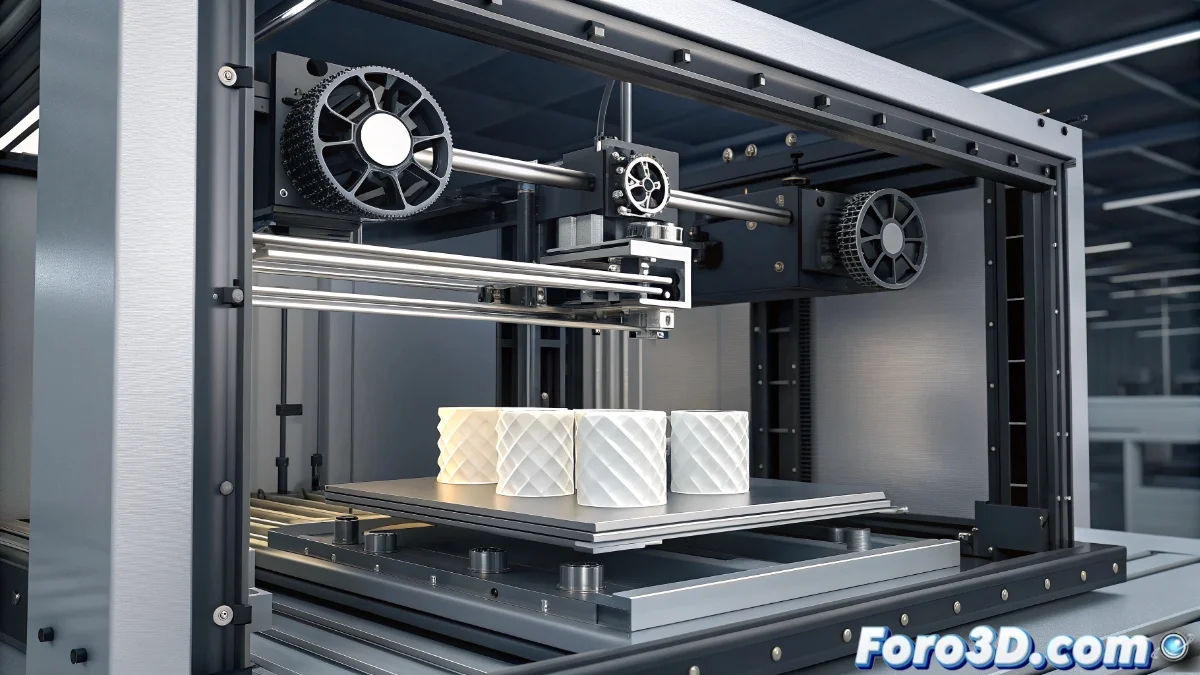

Felixprinters presents the Pro L/XL 3.0 series for advanced industrial manufacturing

The company Felixprinters has revolutionized the market with the launch of its new Pro L/XL 3.0 series, specifically designed for industrial environments that demand maximum productivity and adaptability. These 3D printers stand out for their modular construction that allows customizing and upgrading the equipment as manufacturing needs evolve. With print volumes reaching 600 × 400 × 600 mm, they can handle large-scale parts without sacrificing speed, reaching up to 150 mm/s under optimal conditions. This combination of size and speed makes them ideal tools for companies seeking to optimize their additive manufacturing processes 🚀.

Technical features and operational flexibility

The series incorporates dual extrusion as standard, facilitating the use of soluble support materials or printing with two different filaments on the same part. The automatic calibration system ensures that every job starts with a perfectly leveled bed, reducing preparation times and minimizing errors. Additionally, its modular design not only simplifies maintenance and replacements but also allows adapting the machine to new technological advances without needing to replace the entire equipment. This versatility is complemented by compatibility with a wide range of materials, from PLA and ABS to more advanced technical composites, expanding possibilities in demanding applications 🔧.

Key advantages of the Pro L/XL 3.0 series:- Extensive print volumes of 600 × 400 × 600 mm for large-sized parts

- Print speeds of up to 150 mm/s without compromising quality

- Standard dual extrusion system for support materials and multiple filaments

The modularity of these printers not only reduces maintenance costs but also ensures that companies can upgrade their equipment as new technologies emerge, offering a long-term investment.

Applications in contemporary industry

These printers are aimed at sectors where speed and customization are crucial, such as rapid prototyping, tooling creation, molds, and final part production. Their ability to work with multiple materials makes them suitable for manufacturing functional components that require specific properties, such as heat resistance or rigidity. In production environments, the possibility of quick changes and modular upgrades means less downtime and greater adaptability to market demands. Thus, the Pro L/XL 3.0 series not only accelerates manufacturing but also offers a durable and scalable solution for companies seeking to integrate 3D printing into their value chains 💼.

Main industrial applications:- Rapid prototyping for product development and design validation

- Manufacturing of custom tooling and molds with high precision

- Production of final parts using advanced technical materials

Conclusion: Innovation without limits in additive manufacturing

The Pro L/XL 3.0 series from Felixprinters represents a significant advancement in industrial 3D printing, combining large volume, high speed, and modularity in a single machine. Although with so many advanced features, one might almost expect it to make coffee too, for now it limits itself to revolutionizing additive manufacturing without adding caffeine to the process. These printers not only improve efficiency in production but also offer a flexible and upgradable platform to face the future challenges of the industry 🌟.