When 3D Printing Puts on Its Work Clothes

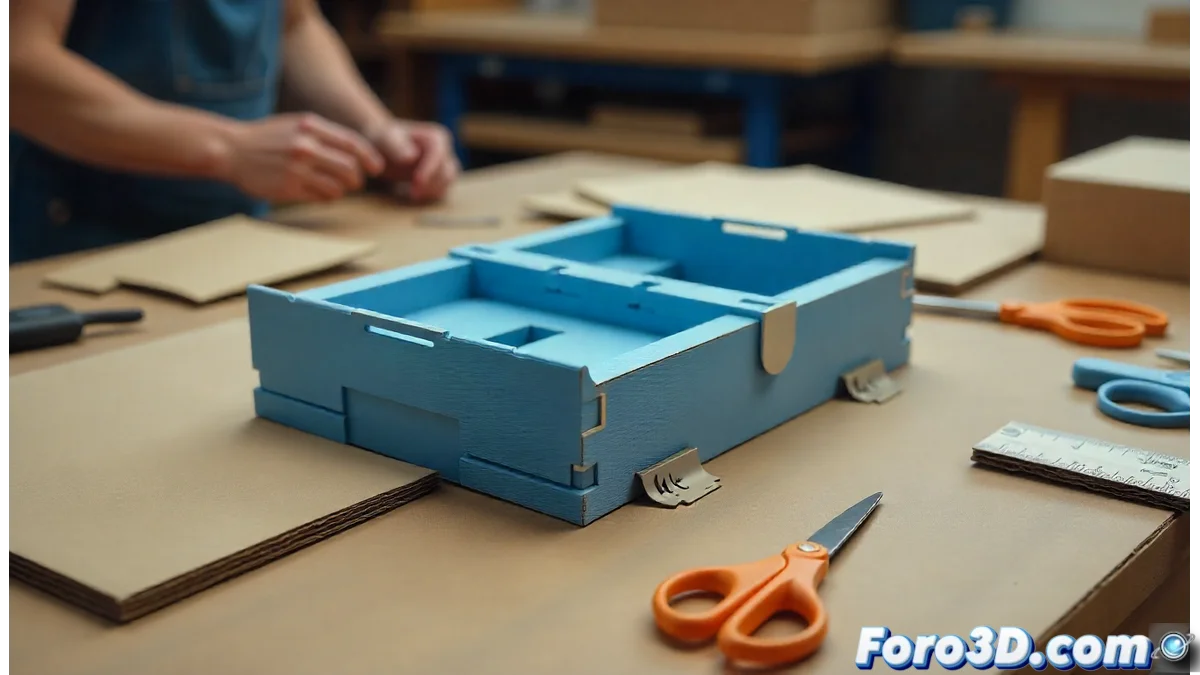

Excamera Labs has presented an ingenious solution to a common problem in small workshops and production lines: manual box assembly. Its prototype is a fully 3D-printed tool that guides each step of the assembly, from folding the flaps to fitting the tabs. 🧰 The idea is as simple as it is effective: use the versatility of parametric design and additive manufacturing to create customized assembly aids, reducing human errors and speeding up processes without the need to invest in expensive industrial machinery. It is the democratization of production tools.

A Modular Design to Adapt to Any Box

The key to this tool is its modularity. Instead of being a rigid piece, it is conceived as a system of components that can be printed and combined according to the dimensions and type of box to be assembled. 📦 Through printed slots, guides, and stops, the operator only has to follow the physical indications of the tool to perform a perfect assembly. If the box design changes, it is enough to modify the CAD file and print the new modules, an agility impossible to achieve with traditional metal tools.

Accessible Materials and Local Production

One of the greatest successes of the concept is its reliance on common FDM 3D printing materials, such as PLA, PETG, or ABS. This means that any workshop with a basic 3D printer can manufacture its own tools on demand. 🌍 The need to wait for orders from external suppliers or store obsolete tools is eliminated, promoting more local and sustainable production. The carbon footprint associated with transporting heavy tools is drastically reduced.

The best tool is not always the most robust, but the one that adapts fastest to changes.

Advantages for the Small Producer

For a small entrepreneur or a workshop with variable productions, the advantages are significant. The initial cost is much lower than that of a steel or aluminum tool, and the development time for a functional prototype is reduced from weeks to hours. 💡 The ability to test a design, identify flaws, and generate an improved version on the same day greatly accelerates iteration and optimization of packaging processes. It is the agile philosophy applied to physical manufacturing.

Practical Limitations to Consider

Like any prototype, it has its limitations. The durability of printed plastic is not comparable to that of metal in intensive and continuous production environments. Wear from friction or exposure to high temperatures can affect its precision and lifespan. ⚠️ Additionally, the final quality of the tool depends directly on the printer's calibration and the skill of the person handling it. It is not a solution for a 24/7 assembly line, but for more modest and variable productions.

The key points that define this tool are:

- Adaptability: It is quickly redesigned and printed for new box formats.

- Error Reduction: Physical guides minimize incorrect assembly.

- Economy: Low material cost and possibility of on-site manufacturing.

- Sustainability: Only what is needed is produced, avoiding unnecessary stock.

The Future of Specialized Tools?

This Excamera Labs prototype points to a broader trend: mass customization of low-cost tools through 3D printing. In the future, it could be common for each company to design and produce its own specific assembly aids, sharing files between different production plants. 🔧 This empowers technicians and designers, giving them total control over their processes without depending on large tooling manufacturers.

So, while large factories rely on robots and heavy machines, small workshops can find in a simple 3D printer their best ally. After all, innovation doesn't always come in a giant container; sometimes, it fits on the print bed. And ironically, the tool that assembles boxes... arrives in a box! A perfect cycle. 😄