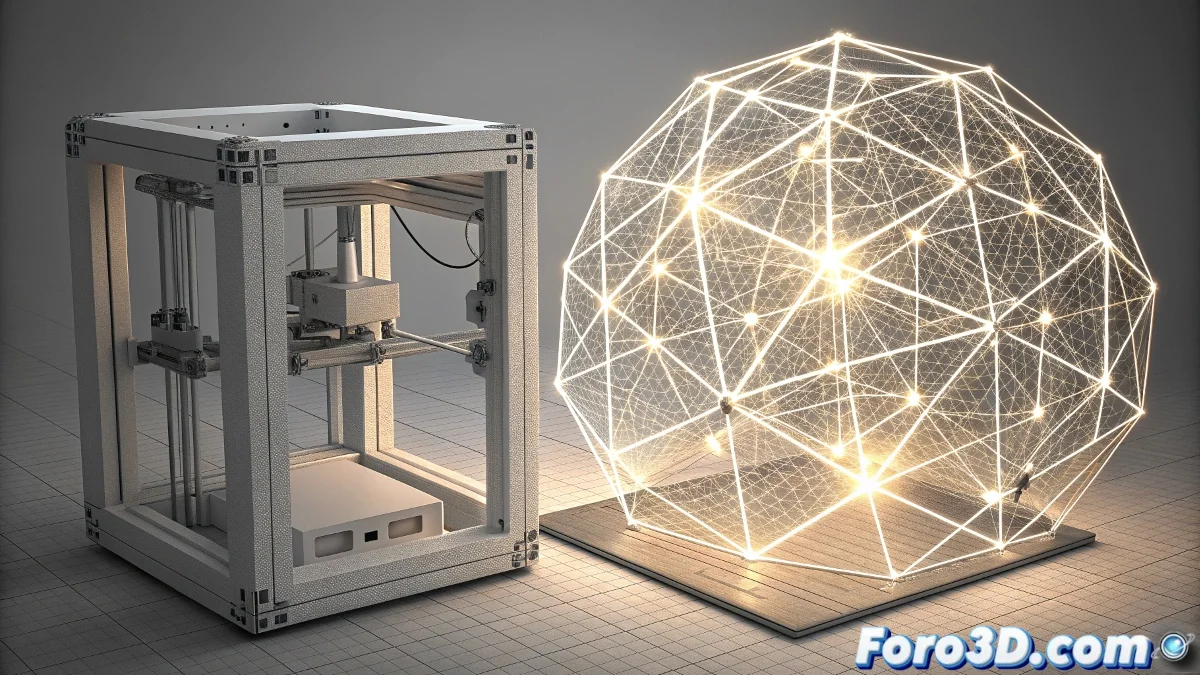

When Polygons Turn into Real Objects

Polygonal modeling for 3D printing represents that fascinating intersection where the digital materializes into the physical. Unlike modeling for rendering or animation, where visual appearance is priority, here each triangle and quadrilateral must meet specific structural requirements to survive the journey from software to the real world. Understanding this fundamental difference is the first step toward creating models that not only look good on screen but also print successfully.

The central philosophy revolves around creating solid and manifold geometry - a term that describes closed meshes without holes or overlapping faces. While visual rendering can tolerate certain topological irregularities, 3D printing demands mathematical precision because every imperfection translates directly into a physical problem. Slicing software needs to perfectly interpret the model's outer surface to generate the instructions that will guide the printer.

Fundamental Principles of Printable Modeling

- Manifold geometry where each edge belongs exactly to two faces

- Minimum thicknesses that exceed the printer's nozzle diameter

- Clean topology without inverted faces, duplicate vertices, or inconsistent normals

- Polygon optimization balancing visual detail with printing efficiency

The Science Behind the Perfect Mesh

Creating models for 3D printing requires thinking like an engineer as well as an artist. Every design decision must consider how the material will behave during printing and afterward. The laws of physics become silent collaborators in the creative process: gravity affects overhangs, material shrinkage influences final dimensions, and internal stresses can cause deformations. The successful modeler anticipates these factors from the first vertex.

A good 3D model looks great on screen, a great 3D model prints perfectly

Specific techniques include the strategic use of triangulated versus quadrangulated faces, where triangles provide structural stability but squares subdivide more cleanly. Chamfers and fillets are not just aesthetic elements, but structural reinforcements that distribute stresses at critical corners. The ideal print orientation must be considered during modeling, as it directly affects the object's final strength.

Common Mistakes and How to Avoid Them

- Non-manifold faces that create geometry impossible to interpret

- Too-thin walls that collapse during printing

- Unnecessarily dense topology that slows down processing

- Mesh intersections that create non-printable negative volume

Mesh analysis tools become indispensable allies, identifying problems that the human eye might overlook. Most modern 3D modeling software includes specific functions for print preparation, from thickness checkers to overprint detectors. Mastering these tools separates hobbyists from professionals in the field of digital manufacturing modeling.

Those who think that modeling for 3D printing is the same as for animation have probably had to learn the hard way why their creations didn't survive the printing process 🖨️