Closed-Well Enhanced Geothermal Systems: A Fracking-Free Alternative

The search for clean and constant energy leads to exploring the heat stored beneath our feet. Closed-Well Enhanced Geothermal Systems (EGS) represent an innovative approach that aims to harness this resource without the controversial methods of hydraulic fracturing. This technology builds an artificial circuit in the depths to capture energy in a more controlled manner. 🔄

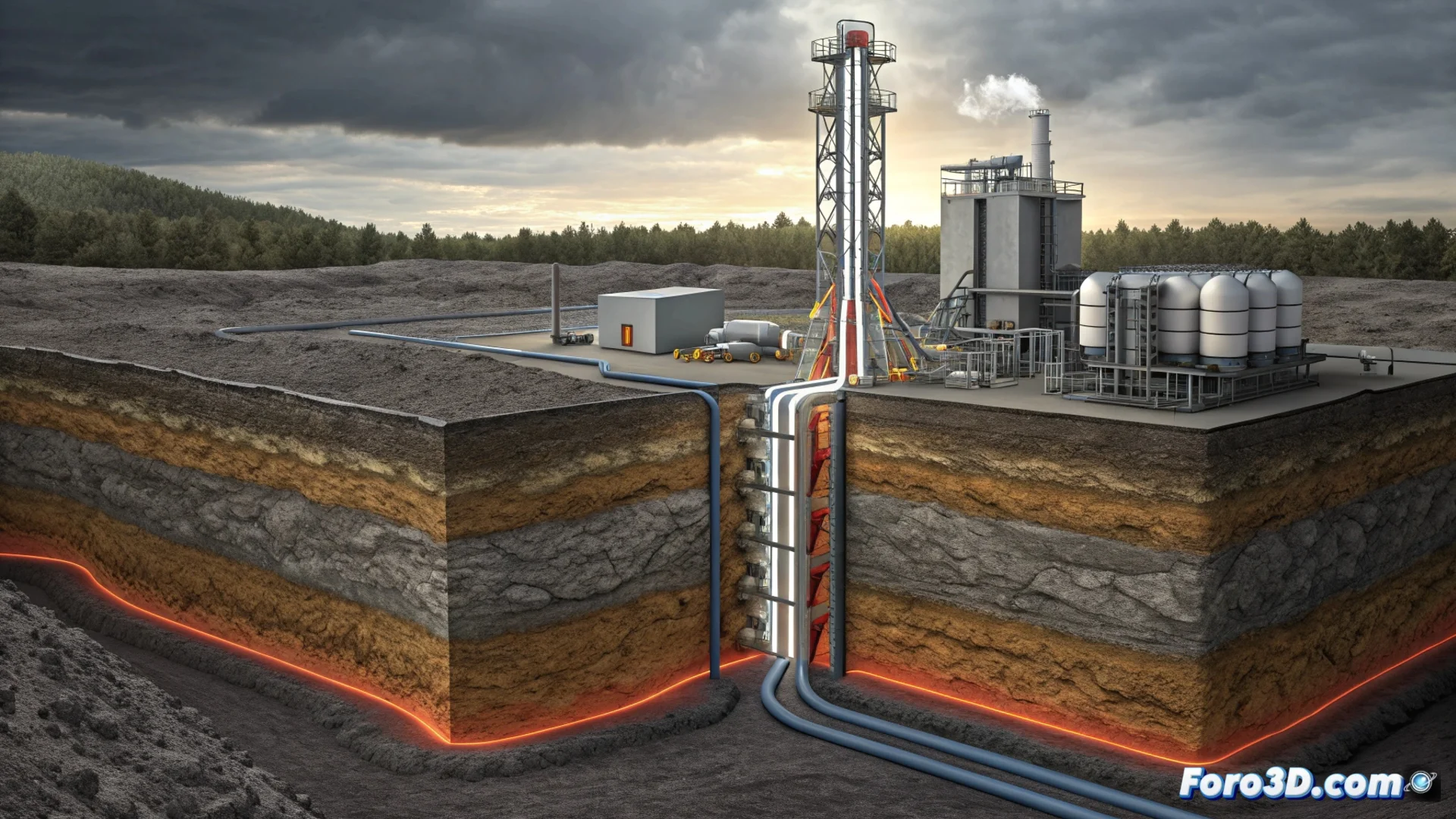

The core of the system: a deep and isolated circuit

The operation is based on drilling two wells that reach rock layers with temperatures above 150°C. These wells are connected underground, creating a completely sealed circuit. Inside it, a fluid, typically water, circulates without ever coming into direct contact with the geological formation. Heat is transferred by conduction through the walls of specialized pipes, designed to withstand extreme conditions.

Key advantages of this sealed design:- Eliminates fracking: It does not require fracturing the rock to create permeability, as the fluid never leaves the installed pipes.

- Minimizes environmental risks: By confining the working fluid, the potential to contaminate underground aquifers is drastically reduced.

- Controls seismicity: The absence of high-pressure injection into rock formations reduces the possibility of inducing perceptible microseisms.

Semantics are crucial in geothermal energy. A closed and sealed circuit operates under fundamentally different principles than systems that rely on fracturing the subsurface.

Technical and economic challenges to overcome

Although the concept is promising, bringing closed-well EGS to commercial scale faces considerable obstacles. Drilling to several kilometers deep is a complex process that entails high costs. The materials for the pipes must withstand decades of exposure to intense heat, high pressure, and corrosive environments.

Critical areas requiring optimization:- Heat transfer efficiency: Heat moves more slowly from the rock to the fluid inside a pipe compared to a fractured reservoir filled with water.

- Drilling costs: Developing faster and more economical drilling technologies is essential for the generated energy to be price-competitive.

- Material durability: Advanced alloys and composites are needed to ensure the long-term integrity of the circuit.

The path to commercial viability

Pilot projects worldwide are testing designs for more efficient heat exchangers and optimized construction methods. The ultimate goal is to demonstrate that electricity can be generated reliably, safely, and at a cost that competes with other energy sources. Beyond the technical challenges, there is a communication challenge: clearly differentiating this technology from others that also drill deeply, to gain public and political acceptance. The future of this next-generation geothermal energy depends on overcoming these fronts simultaneously. ⚙️