The Flexible Revolution: How Elastomers are Transforming 3D Printing

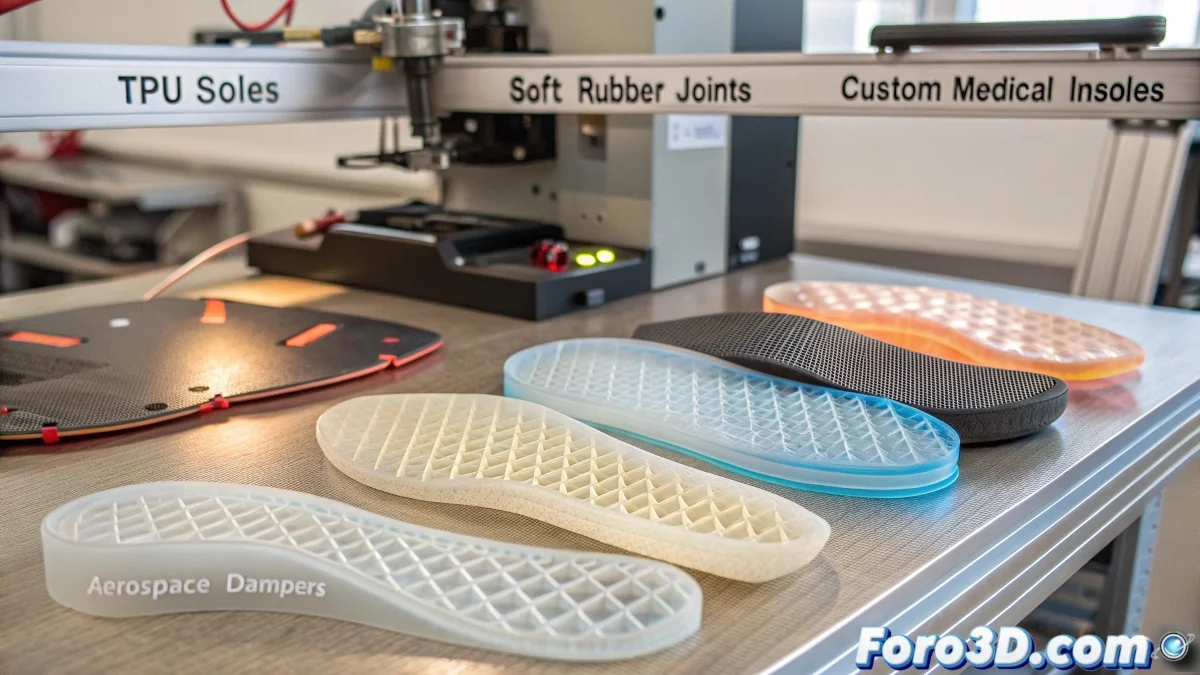

The world of 3D printing is undergoing a radical shift toward flexibility. Elastomers, those materials that combine the strength of plastics with the elasticity of rubber, are paving the way for new industrial applications. 🌈

If 3D printing was once synonymous with rigidity, now we can say it has become more... elastic in its approaches.

A Market Stretching Toward the Future

The numbers speak for themselves: from 2.5 billion dollars in 2021 to a projected 6.1 billion in 2030. This annual growth of 7.1% demonstrates how key industries are adopting these materials for:

- Automotive components that absorb impacts

- Customized medical devices

- Resistant aerospace parts

Dominate Flexibility in Your 3D Projects

For digital creators, these materials open up a world of possibilities. In Blender, you can simulate their behavior using:

- The Soft Body modifier for realistic animations

- Shaders with subsurface scattering for that rubbery look

- Physics simulations for deformable objects

Renders in Cycles or V-Ray can perfectly capture that characteristic appearance of elastomers, especially when combined with normal maps and subtle displacement. 🎨

Materials That Change the Game

From TPU to advanced silicones, these materials are not only more flexible, but also smarter and more versatile. They enable the creation of functional, ready-to-use parts with properties that previously required complex manufacturing processes.

So the next time you see a 3D printed object, don't try to bend it... unless you know it's made of elastomers. Though if it breaks, you can always say you were testing its elastic limits. 😉