Atomic Structures Revolutionize Metal Printing

A scientific breakthrough in the field of materials science is transforming the possibilities of additive manufacturing. Researchers have discovered unusual atomic formations that enable the printing of aluminum alloys previously problematic for this technology.

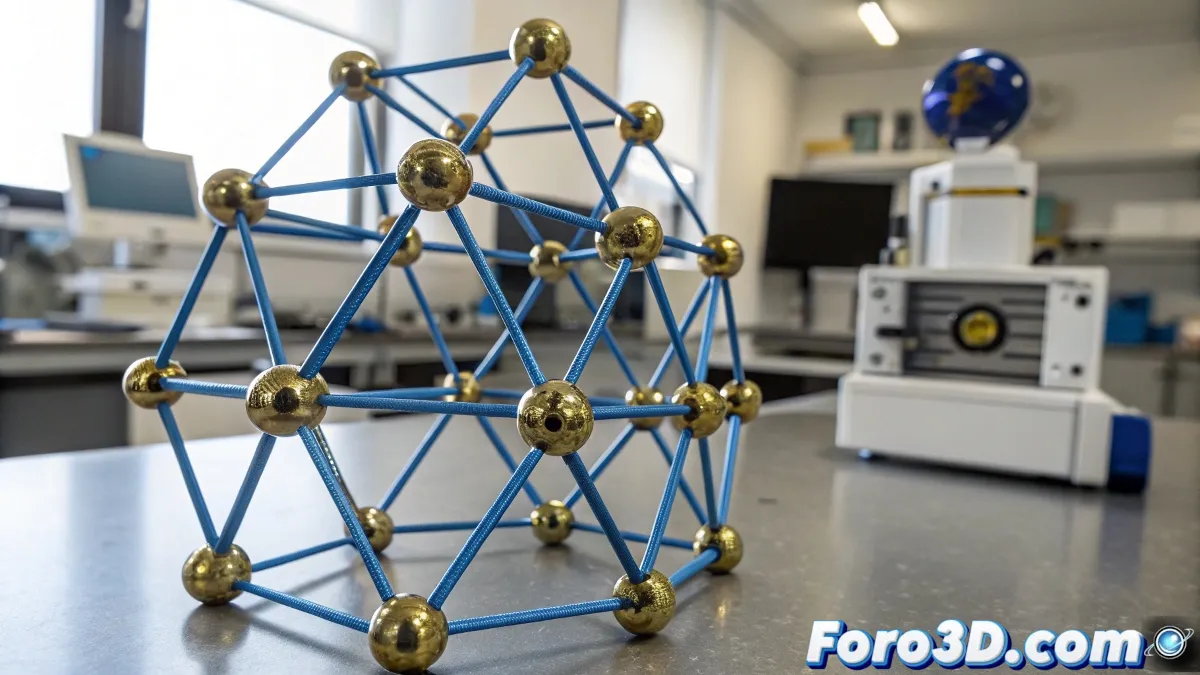

The Mystery of Non-Periodic Patterns

Quasicrystals represent a fascinating anomaly in the world of crystalline structures. Unlike regular atomic patterns, these formations exhibit symmetries that were considered impossible until their discovery in 1982. Their appearance during the 3D printing process explains the unique properties of certain alloys.

"The presence of these unusual atomic structures acts as microscopic reinforcement, preventing the fractures that affect other materials"

Overcoming Thermal Barriers

The main challenge in 3D metal printing lies in the extreme temperatures of the process. While pure aluminum behaves predictably at 700°C, the additive manufacturing environment demands much more rigorous conditions:

- Temperatures exceeding 2,400°C

- Controlled rapid cooling

- Microstructure stabilization

Promising Industrial Applications

This discovery opens new possibilities for sectors demanding advanced materials. The characteristics of these alloys make them particularly suitable for:

- Structural components in aeronautics

- Thermal transfer systems

- High-demand mechanical elements

Future of Advanced Manufacturing

Understanding these phenomena at the atomic level allows for the design of materials specifically adapted to 3D printing processes. This knowledge not only solves current technical problems but also establishes the foundation for the development of new generations of metal alloys.

Research continues to explore how to optimize these unusual atomic structures for specific industrial applications, marking a milestone in the evolution of digital manufacturing.