The Art of Connecting Joints with Smart Geometry

Creating cylinders that automatically orient between two joints in Maya is like establishing digital bridges that dynamically adapt to their anchor points 🌉. This technique is invaluable for mechanical systems, robotic limbs, or any situation where geometry needs to connect two moving points while maintaining correct orientation and proportion.

Preparation: The Importance of Local Axes

The success of this technique critically depends on the correct alignment of the cylinder's local axes. A poorly oriented axis will result in erratic rotations regardless of how the constraints are configured.

- Initial Alignment: Orient the cylinder along the Y axis generally

- Freeze Transformations: Reset transformations before applying constraints

- Visual Verification: Use display → transforms → local rotation axes

- Central Pivot: Ensure the pivot is at the geometric center

A well-aligned local axis is like a calibrated compass: it always points in the right direction.

Aim Constraint Setup for Orientation

Aim constraints are the heart of the system, responsible for keeping the cylinder pointing towards the target joint like a digitally guided missile.

- Aim Vector: Configure according to the cylinder's orientation axis (usually Y)

- Up Vector: Set the axis that maintains vertical orientation

- World Up Type: Use "object rotation" for greater stability

- Constraint Weights: Adjust influence for smooth blending

Controlling the Second End with Complementary Techniques

While the aim constraint controls one end, the other end requires additional approaches to complete the connection system.

- Secondary Aim Constraint: For fine control of the opposite end

- Point Constraint: To fix position without affecting rotation

- Pole Vector Constraint: For twist and intermediate orientation control

- Expression-Based Control: For complex custom behaviors

Stretch Systems for Adaptable Length

For cylinders that must stretch or compress between joints, stretch deformers add that crucial layer of mechanical realism.

- Native Stretch Deformer: Specific deformer for stretching

- Distance Expressions: Mathematical calculation of length based on joint positions

- Volume Preservation: Maintaining volume during compression

- Scale Limiters: Preventing unwanted extreme stretching

Common Practical Applications

This technique finds application in numerous animation and rigging scenarios where dynamic connection between elements is needed.

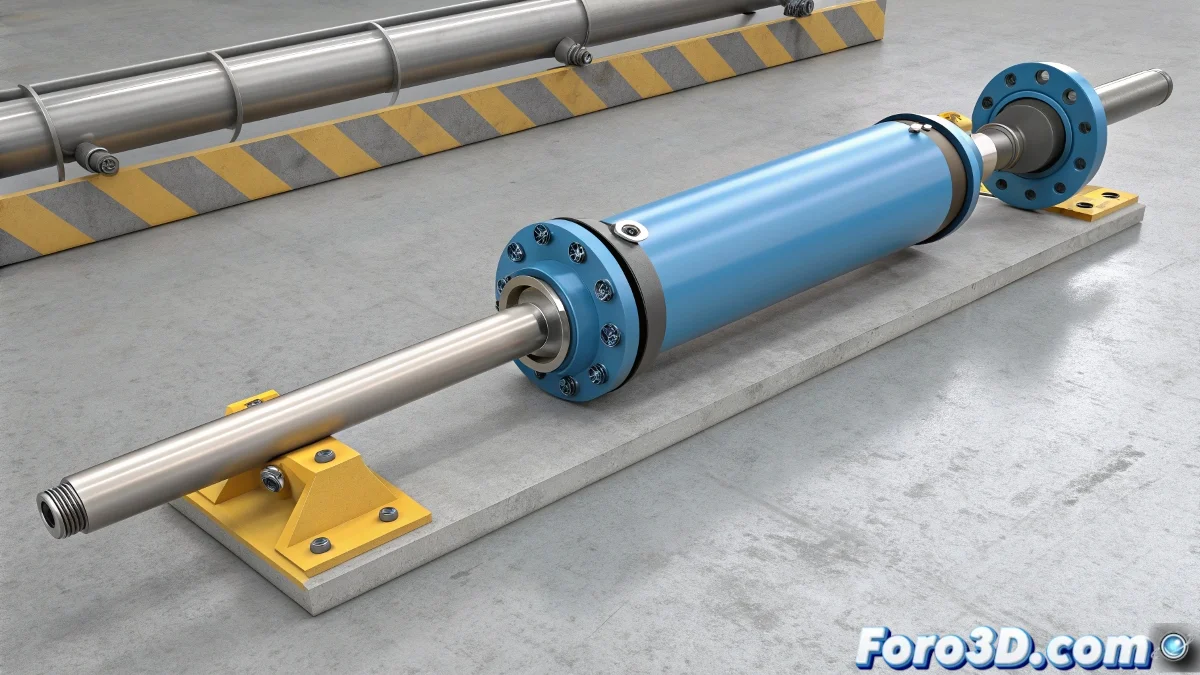

- Robotic Arms: Connections between mechanical parts

- Hydraulic Systems: Realistic pistons and hydraulic cylinders

- Organic Connections: Tentacles, appendages, and biological extensions

- UI Elements: Visual connections in animated interfaces

Optimization and Troubleshooting

Like any technical system, problems can arise that require debugging and optimization.

- Gimbal Lock: Avoid by using quaternions or Euler filters

- Sudden Flip: Adjust up vector objects for greater stability

- Performance: Use efficient constraints for complex systems

- Render Considerations: Verify that deformations render correctly

Professional Workflow

Implementing this system consistently requires following a specific methodology to ensure predictable results.

And when your cylinder decides