Constraint-Based Rigging: Beyond the Parent-Child Hierarchy

In the field of 3D animation and rigging, there is a paradigm that elevates control to a superior level: constraint-based rigging. This approach goes far beyond the parent/child hierarchy system, establishing a network of logical rules and programmatic links that precisely govern the behavior of bones and objects. Imagine building a puppet system where each string responds to a specific physical law, rather than simply pulling a chain. 🎭

Why Does It Surpass the Classic Hierarchy?

The main advantage of this method is its non-destructive flexibility and granular control. While a rigid hierarchy can suffer from gimbal lock or unexpected deformations, a network of constraints allows for creating complex relationships of orientation, position, and scale. This is essential for systems like highly stable inverse kinematics (IK), aiming mechanisms (aim) for eyes or cameras, and the simulation of realistic mechanical elements like pulleys or complex joints. The same element can be influenced by multiple controllers, facilitating secondary animations and follow-through in a much more intuitive and robust way. 🧠

Key Benefits of the System:- Non-Linear Control: A bone can be influenced by several controllers at once, breaking the linearity of the parent-child chain.

- Error Prevention: Minimizes common issues like gimbal lock and unwanted rotations in complex hierarchies.

- Modular and Reusable Rigs: Facilitates the creation of control systems that can be adapted or replicated in different assets.

Mastering constraint-based rigging requires thinking like an engineer, ensuring that your complex logical network doesn't turn into an impossible knot to untangle in the middle of the night.

Practical Applications and Workflow

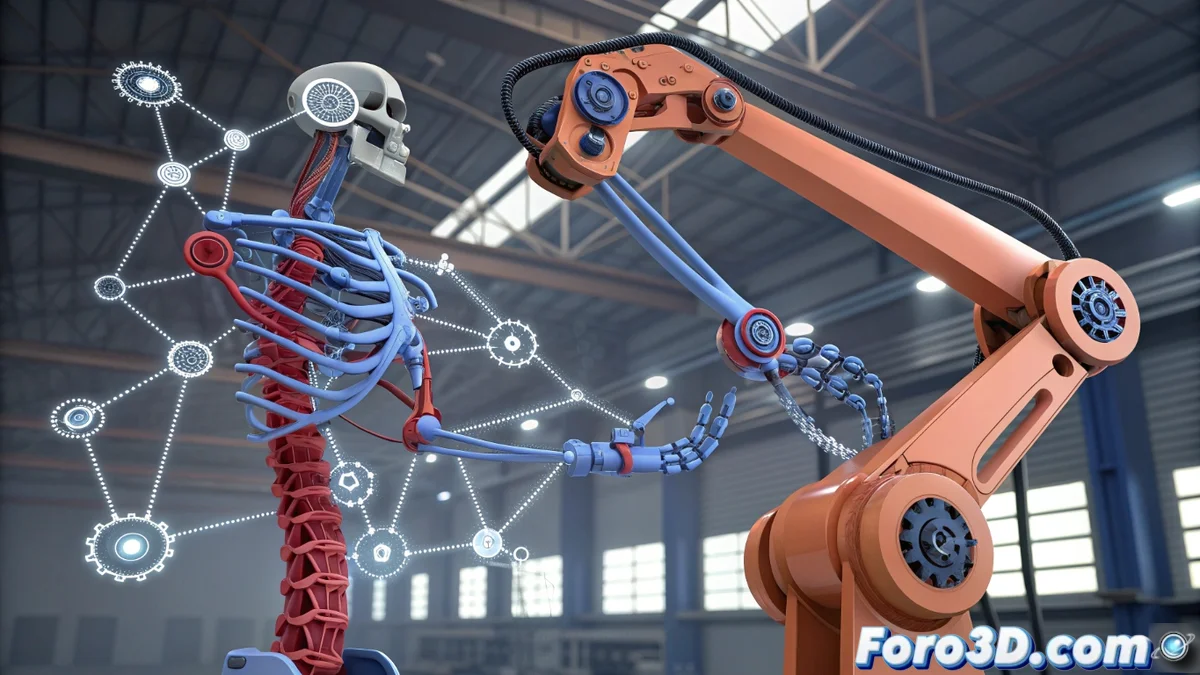

This paradigm is the ideal choice for assets with precise mechanical movement. It is indispensable in creating rigs for robotic characters, vehicles with realistic suspension systems, industrial machinery, or any element that requires predictable and complex kinematic behavior. In applications like Blender, Maya, or 3ds Max, it is implemented through a powerful toolbox that includes transformation constraints, stretch-to, limit distance, and above all, the powerful drivers system. Drivers allow linking parameters to mathematical expressions, other bones, or properties, weaving a mesh of intelligence that defines all possible interactions within the rig. ⚙️

Common Tools in 3D Software:- Transformation Constraints: To copy or limit the location, rotation, or scale of an object relative to another.

- Drivers System: The heart of advanced control, enabling data-based, expression-based, and logical relationships.

- Specialized Constraints: Such as Stretch To for realistic elongation or Limit Distance to maintain defined spaces.

The Art and Engineering of Control

Adopting constraint-based rigging implies a mindset shift: from sculptor-artist to engineer-artist. Planning is crucial. It begins by defining a skeleton of bones and a network of visual controllers, then "wiring" between them with this mesh of logical rules. The result is a powerful, organized, and predictable control system. However, its complexity demands careful design to avoid creating circular dependencies or networks so tangled that they are difficult to debug. The reward, however, is a level of control and realism in animation that traditional methods simply cannot match. 🏗️✨