When Plastic Conducts Electricity

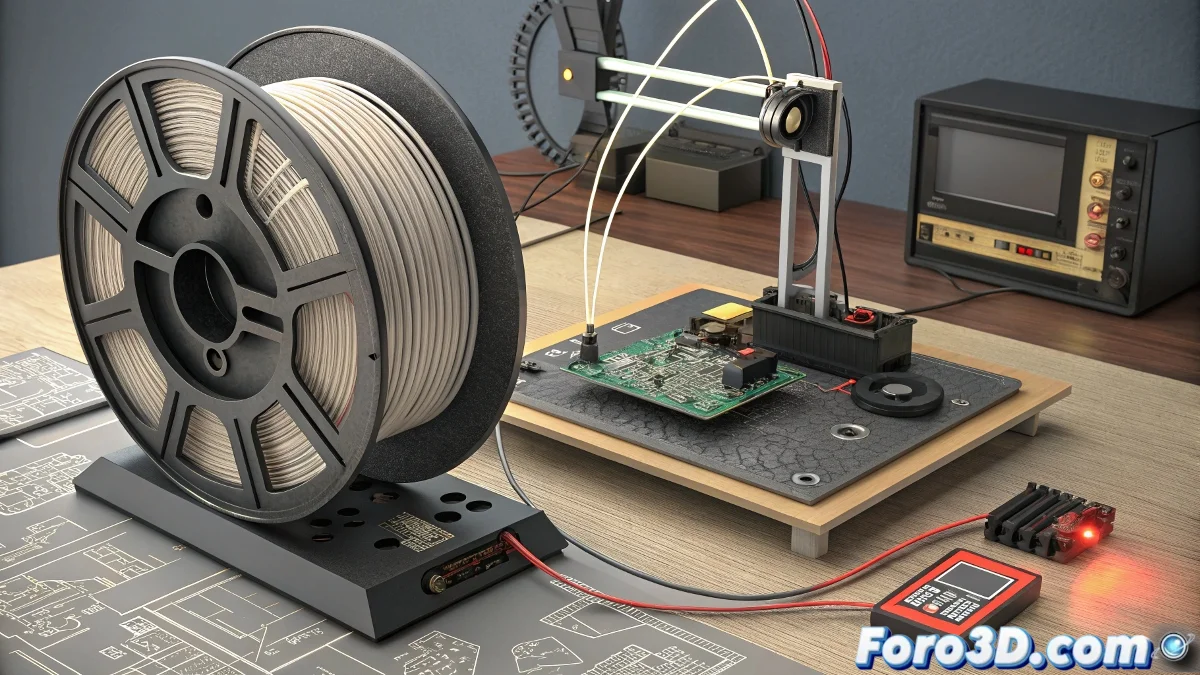

Conductive PLA represents a fascinating fusion between 3D printing and electronics, allowing electrical functionality to be integrated directly into printed parts. This composite material mixes conductive particles, typically carbon or graphene, with a base of traditional PLA, creating a filament that can carry electrical current while maintaining the printing properties of the original material. The result opens up possibilities for rapid prototyping of electronic devices and smart objects.

What makes Conductive PLA unique is its ability to serve as both a structural and conductive material simultaneously. Unlike traditional methods that require inserting wires or printed circuits, this material allows conductive paths to be created directly integrated into the part's geometry. This feature is particularly valuable for wearables, tangible interfaces, and prototypes where the integration between form and function is critical.

Electrical and Mechanical Properties

- Typical resistivity between 0.1 and 30 ohm-cm depending on the formulation

- Compatibility with touch sensors and low-power circuits

- Maintenance of the basic printing properties of standard PLA

- Limited capacity for high currents, ideal for signals and low power

The Art of Designing Printed Circuits

Working with Conductive PLA requires completely rethinking the electronic design approach. Instead of adding components to an existing structure, the designer must integrate conductive paths as an integral part of the 3D geometry. This involves considering factors such as the minimum thickness of traces, the distance between conductors, and the orientation during printing to ensure electrical continuity through the layers.

Conductive PLA transforms the 3D printer into an integrated electronic prototyping machine

Printing with this specialized material presents particular technical challenges. The conductive particles slightly increase abrasiveness, recommending the use of stainless steel or ruby nozzles. The printing temperature is usually similar to standard PLA, between 190°C and 220°C, although some manufacturers recommend temperatures at the upper end to improve conductivity. Precise calibration is crucial to ensure consistent extrusion that maintains conductive properties.

Innovative Applications of the Conductive Material

- Wearable prototypes with integrated sensors

- Tactile interfaces and 3D printed buttons

- IoT devices with built-in antennas and circuits

- Educational tools for teaching electronics

The versatility of Conductive PLA has found applications in diverse fields such as robotics, interactive product design, and academic research. Its ability to create complex three-dimensional circuits that would be impossible with traditional PCB manufacturing methods makes it an invaluable tool for innovators and makers. Although it does not replace metallic conductors for high-current applications, it opens up a world of possibilities for integrated electronics and smart objects. ⚡

Using Conductive PLA is like being an electronics wizard: you can make electricity flow through plastic, although sometimes the resistance makes you feel like you're fighting the laws of physics. 🔮

You can see this product and similar ones in the: store