Complete Guide to Post-Processing Formlabs Ceramic Resin

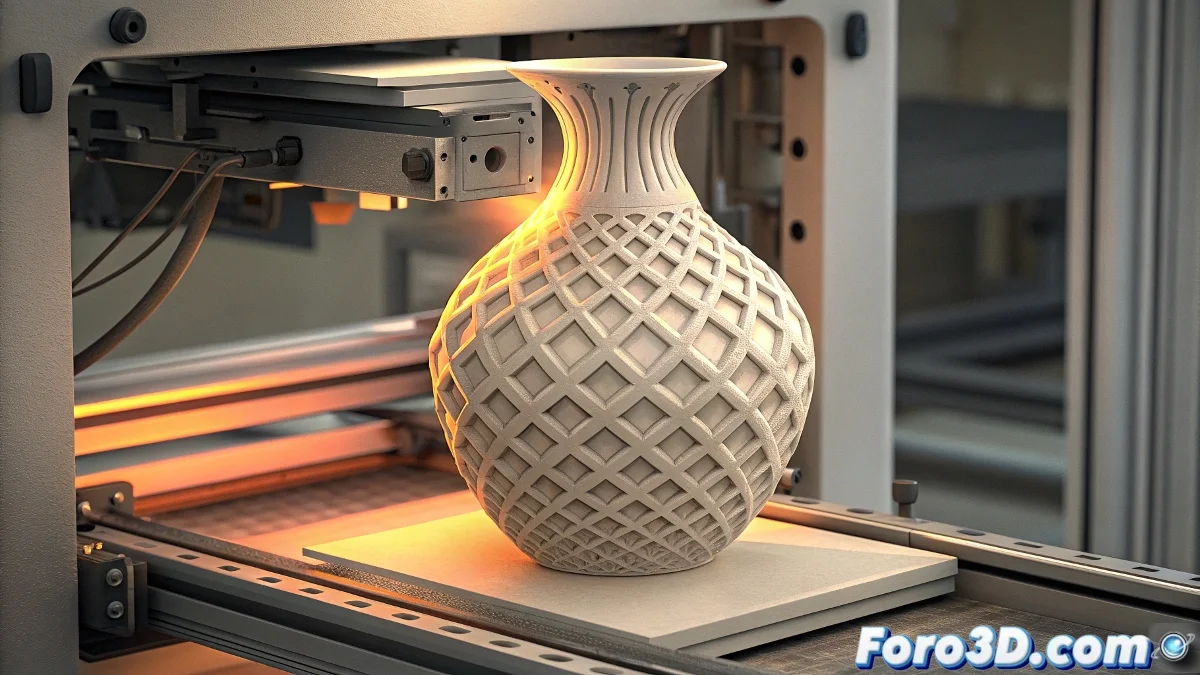

The innovative ceramic resin developed by Formlabs marks a milestone in additive manufacturing of advanced materials, enabling the creation of components that, after a specific thermal treatment, acquire characteristics comparable to those of traditional ceramics. However, the path from printing to the finished product requires impeccable execution of the post-processing stages to avoid imperfections that affect the final performance. 🔬

Mastering Cleaning and Drying Techniques

The initial washing phase must be carried out with Formlabs' official solvent using equipment designed for this purpose, ensuring the complete removal of uncured resin residues without compromising the structural integrity of the part in its green state. It is essential to apply gentle movements and precise timings, complemented by passive drying at room temperature that facilitates the controlled evaporation of residual liquids. The persistence of solvent traces before thermal treatment causes internal stresses during heating, constituting one of the main reasons behind the cracks and deformations commonly reported by users. 💧

Optimized Washing Procedure:- Use exclusively the solvent recommended by the manufacturer in certified cleaning systems

- Apply gentle movements and controlled times to preserve the part's geometry

- Allow complete natural drying before proceeding to firing

Success in the transition from the printed state to the final fired product depends on meticulous control of every process variable

Advanced Thermal Treatment Protocol

The firing cycle must begin with an extraordinarily progressive heating curve, not exceeding 2°C per minute until reaching 200°C, maintaining this temperature for half an hour before gradually increasing to the maximum sintering temperature. During the cooling stage, it is equally crucial to reduce the temperature in a programmed manner, preferably within the same sealed furnace without opening the door until dropping below 60°C. This controlled thermal process enables the ceramic particles to restructure gradually without generating critical stresses that lead to observable structural failures. 🔥

Critical Firing Stages:- Start with a maximum heating ramp of 2°C per minute up to 200°C

- Maintain stable temperature for 30 minutes before continuing the increase

- Cool in a controlled manner inside the closed furnace to room temperature

The Technological Paradox in Printed Ceramics

It is particularly interesting to observe how, after investing in 3D printing technology with micrometric precision, the final result largely depends on replicating ancestral pottery methods that past civilizations perfected empirically. This fusion of the modern and the traditional underscores the importance of understanding the fundamental principles that govern material transformation, regardless of the technology used. Formlabs' ceramic resin thus represents a bridge between contemporary innovation and the accumulated artisanal wisdom of centuries. ⚱️