Colibrium Additive Launches the M Line 4 x 1kW System for Additive Manufacturing in Aerospace and Defense

The Colibrium Additive division, part of GE Additive, has officially launched its innovative M Line 4 x 1kW additive manufacturing system, specifically designed to meet the demands of the aerospace and defense sectors. This revolutionary equipment incorporates four 1kW lasers that operate simultaneously, drastically increasing productivity in the production of metal components with complex geometries. The platform is optimized to work with high-strength, high-temperature alloys, common in aerospace applications, ensuring repeatability and quality in every manufactured part. 🚀

Technical Features and Operational Benefits

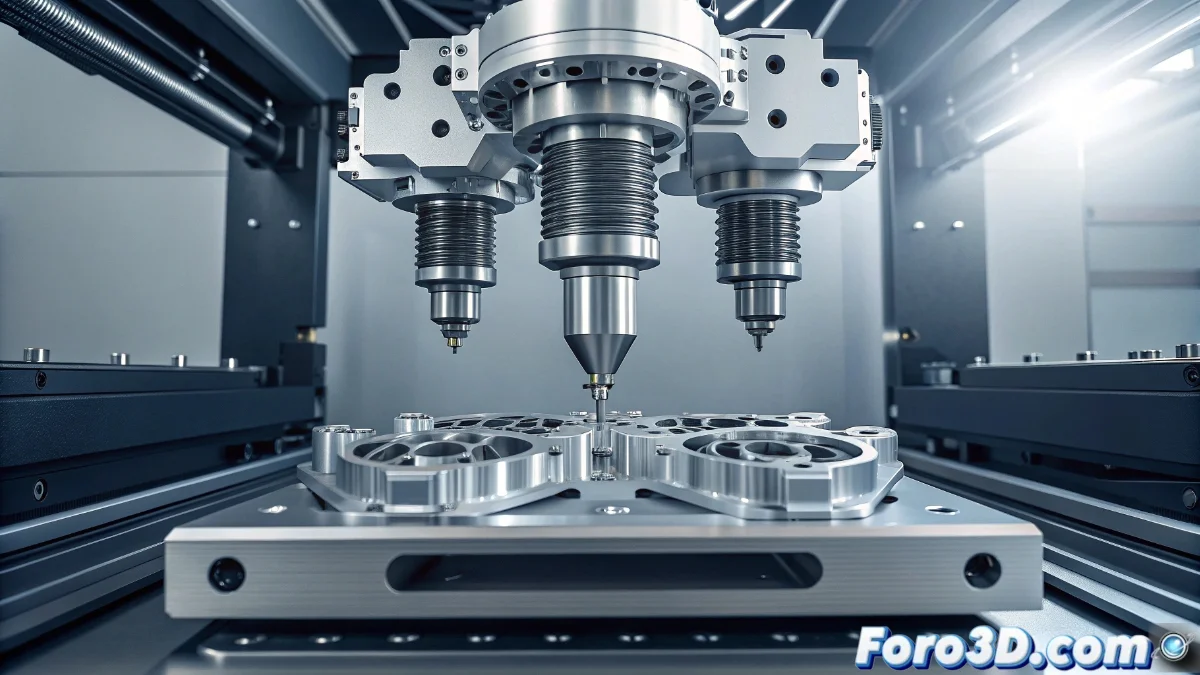

The M Line 4 x 1kW system employs a multi-laser print head that enables higher manufacturing speeds without sacrificing part resolution or mechanical properties. Each laser can operate independently or in coordination, facilitating the creation of intricate geometries and significantly reducing cycle times. Furthermore, the equipment integrates advanced real-time monitoring sensors and control software that automatically adjusts parameters to maintain process stability, resulting in greater efficiency and less material waste, vital aspects in demanding production environments. 💡

Key System Advantages:- Four 1kW lasers working simultaneously to increase productivity

- Capability to manufacture complex geometries with high precision and repeatability

- Real-time monitoring and automatic parameter adjustment to reduce waste

The ability to produce large parts with superior mechanical properties makes it an ideal solution for rapid prototyping and series production.

Applications in Strategic Industries

This system is primarily aimed at manufacturing critical components for turbines, aeronautical structures, and defense systems, where lightness, strength, and precision are essential. Its ability to produce large-scale parts with enhanced mechanical properties positions it as an optimal solution for both rapid prototyping and series production. Companies in the field are already evaluating its implementation to shorten delivery times and reduce costs associated with traditional machining, while increasing design flexibility. ✈️

Key Sectors and Applications:- Manufacturing of components for turbines and aeronautical structures

- Production of defense systems with high-precision requirements

- Rapid prototyping and series production with high-strength alloys

Impact on the Additive Manufacturing Market

With this innovation, Colibrium Additive strengthens its position in the industrial additive manufacturing market, offering a platform that combines speed, precision, and versatility. While some wonder if it will be possible to print entire airplanes from home in the future, the truth is that this system brings that possibility closer by enabling the manufacturing of critical components with unprecedented efficiency. The technology not only optimizes current processes but also opens new opportunities in the design and production of parts for high-demand sectors. 🔧