When Processors Become Silicon Legos

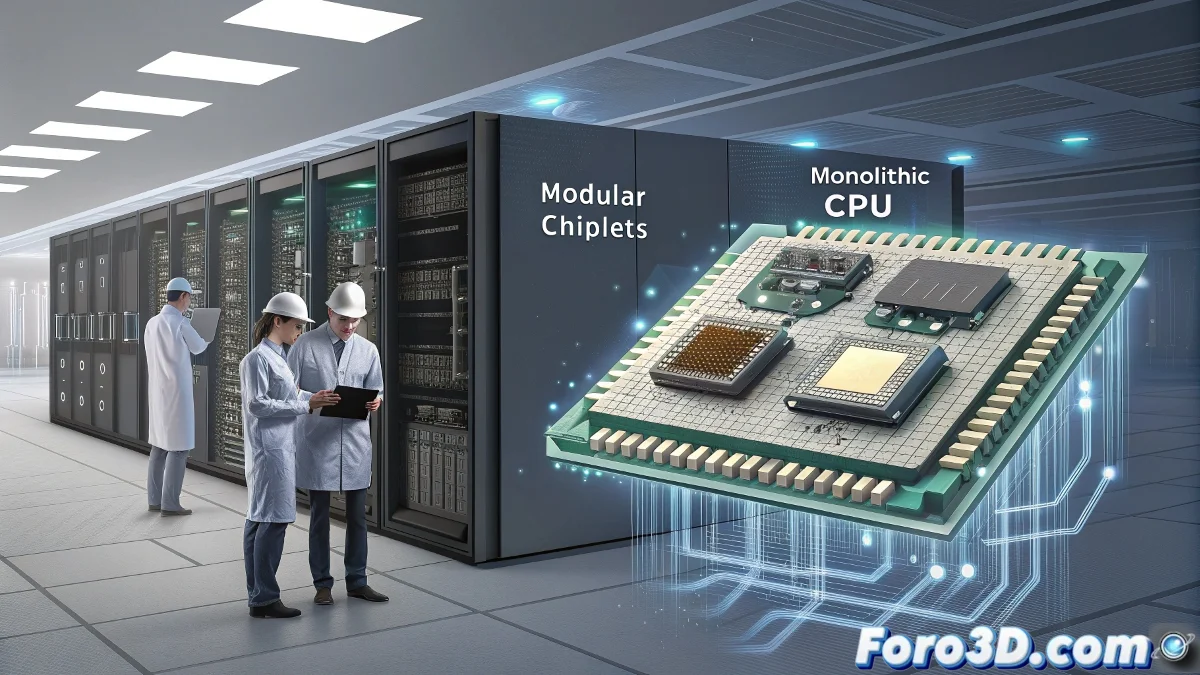

The semiconductor industry is undergoing a quiet revolution that could end decades of monolithic design. Chiplet technology represents a paradigm shift towards modular processors where different components are manufactured separately and integrated into a single package. This approach challenges the traditional Moore's Law by allowing the combination of the best fabrication nodes for each specific function, creating processors that would be impossible to manufacture as a single piece of silicon.

The magic of chiplets lies in their ability to turn physical limitations into optimization opportunities. Instead of trying to cram everything into the same die with the same characteristics, designers can now select the ideal fabrication process for each component: advanced nodes for CPU cores, more mature technologies for I/O, and specialized processes for accelerators. The result is processors that are not only more efficient but also more economical to produce. 💡

In the world of chiplets, specialization beats forced integration

The Anatomy of a Modular Processor

A chiplet-based design breaks down the traditional processor into specialized functional blocks interconnected via advanced packaging technologies.

- Compute chiplets containing the CPU cores with the most advanced nodes

- I/O chiplets manufactured in more economical processes for interfaces and controllers

- Memory chiplets with HBM memory stacks integrated directly into the package

- Accelerator chiplets specialized in specific tasks like AI or encryption

High-speed interconnects like AMD's Infinity Fabric or UCIe (Universal Chiplet Interconnect Express) allow these components to communicate with latency and bandwidth comparable to a monolithic design.

Competitive Advantages Over Traditional Designs

The modular approach offers tangible benefits that explain its accelerated adoption across all market segments.

- Better manufacturing yield by producing smaller dies with a lower probability of defects

- Cost reduction by using optimal processes for each function without compromises

- Greater design flexibility allowing components to be mixed and matched according to needs

- Partial upgradability where only some chiplets need redesign between generations

For professional applications like 3D rendering and simulation, this modularity means being able to have exactly the combination of computing power, memory, and specialized acceleration that each workflow requires.

The Technical Challenges of the Modular Revolution

Despite its advantages, the transition to chiplets presents significant obstacles that the industry must overcome.

Design complexity, testing challenges, and the standardization of interconnections represent barriers that explain why monolithic processors continue to dominate in smaller-scale segments. However, the momentum from consortia like UCIe suggests that interoperability between chiplets from different manufacturers could soon become a reality. 🔧

And if this trend continues, we may soon be able to assemble our processors like Lego pieces... although probably with assembly instructions more complicated than any Lego Technic set 😉