China Automates Manufacturing Joints for Humanoid Robots

During its campaign to promote the Optimus robot, Elon Musk of Tesla repeated that machines must make machines. This concept is now being adopted by companies in China, which have managed to mass-produce articulated components for humanoid robots without human workers intervening. This technical progress represents a fundamental step toward making robots more efficiently and economically. 🤖

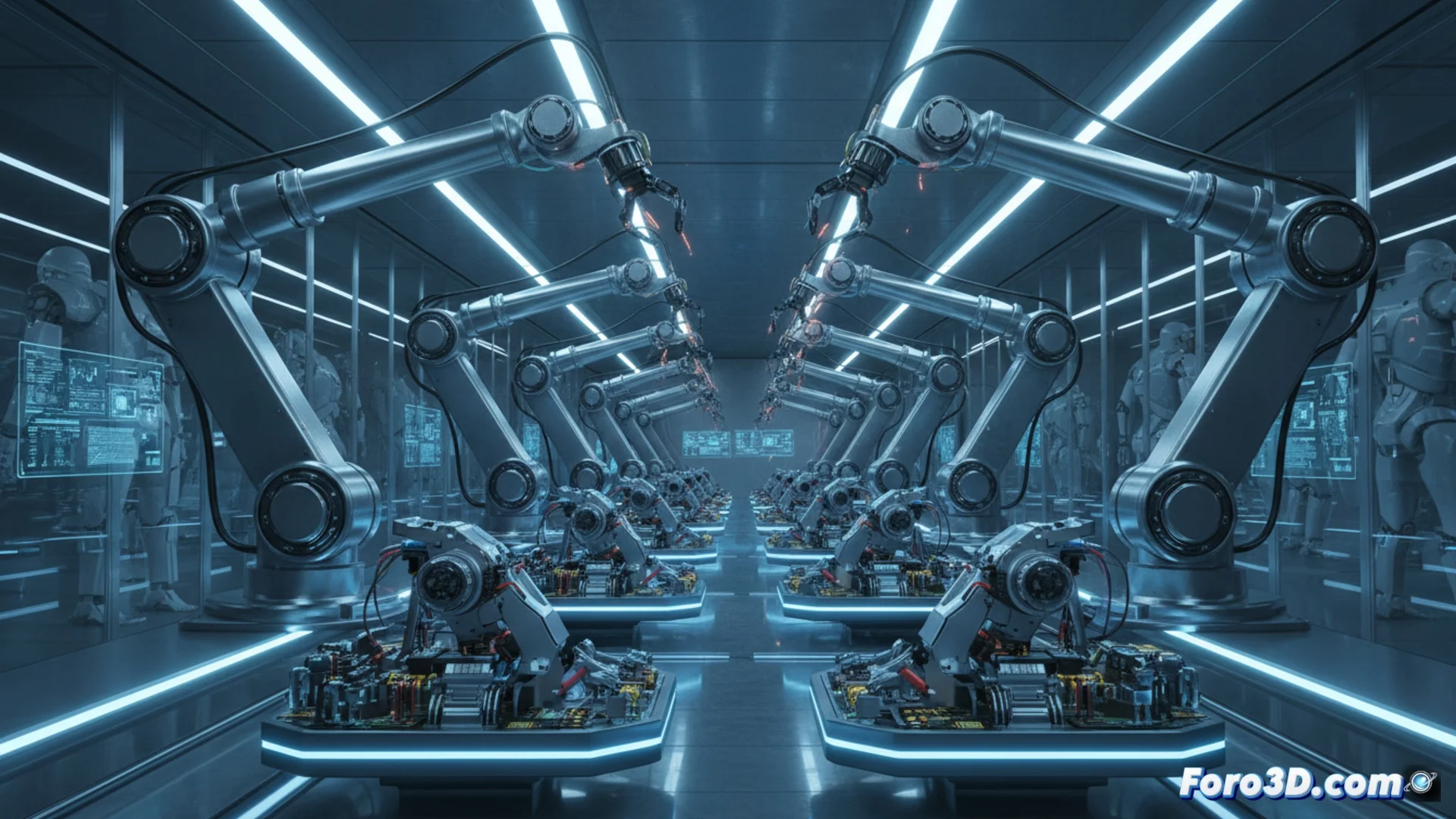

Manufacturing Robotic Components Without Human Intervention

The company AgiBot Innovation Technology has deployed fully automated manufacturing systems to produce high-precision joints. These systems assemble, verify, and prepare the parts for shipment without requiring direct human supervision. The process not only accelerates the production of components but also ensures consistent quality in every unit, which is vital for a humanoid robot to function flawlessly.

Key Features of the Automated Process:- Production lines that operate non-stop without personnel.

- Integrated quality control that tests each joint.

- Automatic packaging of the final product ready for shipment.

"Machines must make machines" - Principle now applied in robotic manufacturing.

Implications for the Robotics Sector

This production method could significantly reduce the costs of making complex robots. By automating the creation of the most sensitive parts, such as joints that emulate wrists or knees, it paves the way for more feasible mass manufacturing. Other global producers are monitoring these advances, as whoever dominates the production of these essential components could lead the service robot market.

Expected Impacts on the Industry:- Significant reduction in the final price of humanoid robots.

- Possibility of scaling manufacturing to much higher volumes.

- Shift in the global supply chain for key robotic components.

The Future of Robotic Manufacturing

It seems that Musk's idea is being taken literally: in the near future, if a robot suffers damage to a joint, another machine will be responsible for repairing it. This cycle of machines maintaining machines could define the next era of industrial automation, making robot production an exclusive domain of automated systems. 🔧