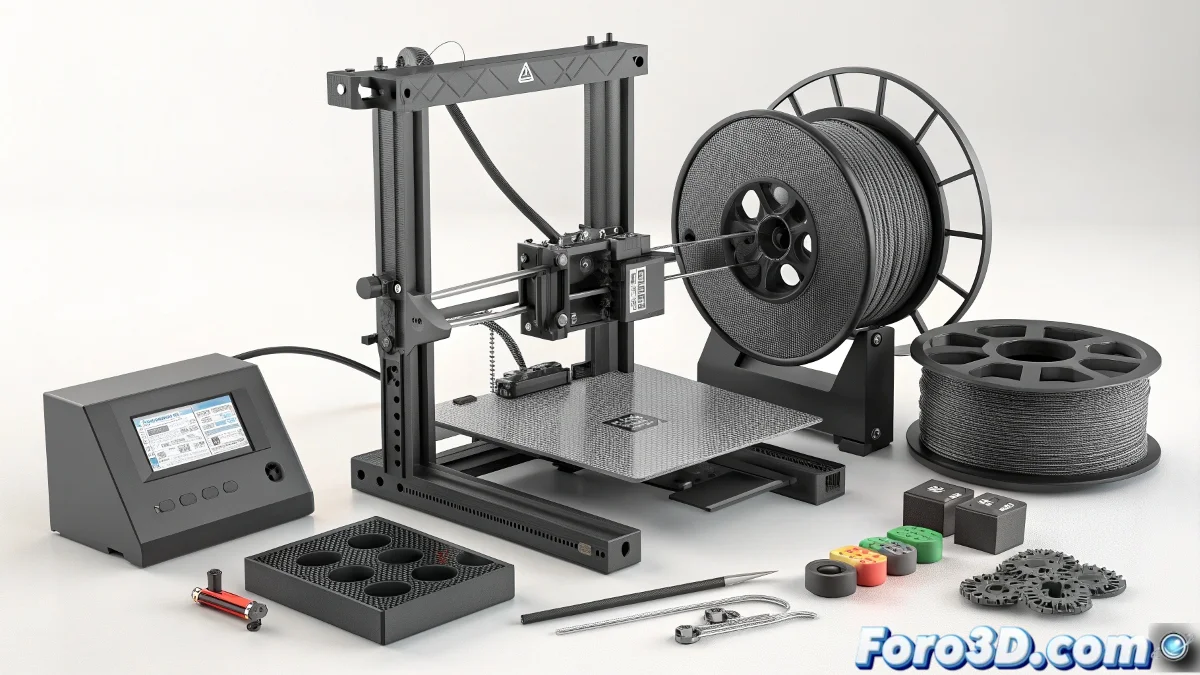

The Revolution of Composites on the Desktop

Carbon Fiber PLA represents the democratization of high-performance composite materials, bringing properties previously reserved for aerospace applications to the realm of home 3D printing. This innovative material blends short carbon fibers with a PLA matrix, creating a composite that retains the ease of printing of the base material while adding exceptional rigidity and dimensional stability. The result is a filament that produces parts remarkably more rigid than standard PLA without sacrificing accessibility.

What makes this material special is its ability to significantly reduce flexing in long and thin parts. While conventional PLA can warp under its own weight in extensive structures, parts printed with Carbon Fiber PLA maintain their shape with rigidity that rivals more advanced engineering materials. This feature makes it invaluable for robotic arms, drone structures, and any application where the stiffness-to-weight ratio is critical.

Enhanced Mechanical Properties

- Stiffness up to 50% higher than standard PLA

- Exceptional dimensional stability with minimal warping

- Significant weight reduction in structural parts

- Characteristic textured surface with professional finish

The Challenge of Extreme Abrasiveness

The main technical consideration with Carbon Fiber PLA is the extremely abrasive nature of the carbon fibers. These particles act like tiny files that quickly wear out conventional brass nozzles. Experienced users exclusively employ hardened steel, ruby, or tungsten carbide nozzles to avoid premature degradation that would affect extrusion diameter and print quality. This is an additional cost that must be considered when adopting this material.

Carbon Fiber PLA offers professional-level rigidity with the accessibility of traditional PLA

Print settings require specific adaptations to optimize results. Temperatures are usually slightly higher than standard PLA, between 200°C and 220°C, and print speed must be reduced to accommodate the higher viscosity of the composite material. Fan cooling can be used moderately, although some users prefer to disable it completely to promote better layer adhesion in structural parts.

Applications Where Carbon Composite Shines

- Drone structures and aerospace components

- Production tools and fixtures requiring rigidity

- Lightweight automotive and robotics components

- Functional prototypes mimicking final production parts

The ability of Carbon Fiber PLA to produce parts with an exceptional stiffness-to-weight ratio has made it a favorite material for technical applications where structural performance is priority. Although its cost is higher than standard PLA and requires investment in specialized nozzles, the mechanical performance it offers more than justifies the investment for serious projects. The unique texture of the finished surface also adds aesthetic value that immediately conveys quality and professionalism. 🏗️

Working with Carbon Fiber PLA is like having a superpower for printers: you transform common plastic into materials that behave like professional composites, even though your nozzle pays the price with every centimeter extruded. 💎

You can see this product and similar ones in the : store