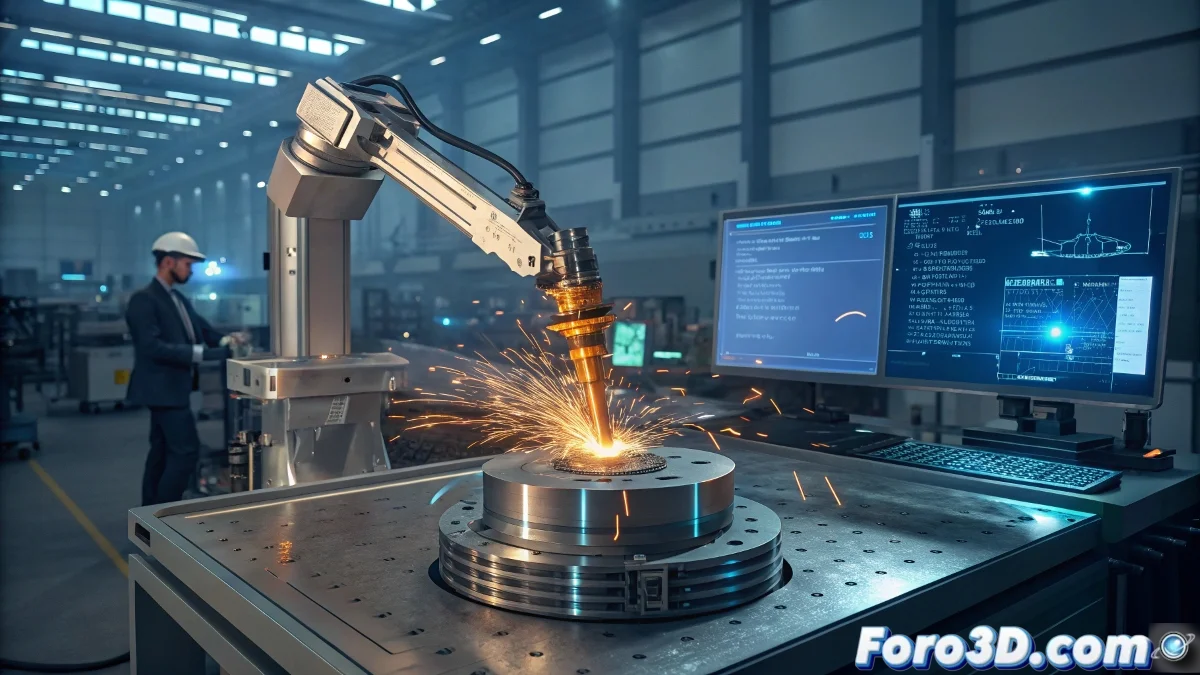

When Alchemy Meets 3D Printing

Caltech researchers have turned metallurgy into a digital design game 🔧🖥️. Their new system allows for printing custom metal alloys as if you were configuring the menu of your favorite fast food... albeit with a bit more science and fewer trans fats.

From Years to Hours: The Miracle of Express Metallurgy

While traditional methods required years of experimentation to develop new alloys, this technology combines predictive modeling with 3D printing to create custom metals in record time ⏱️⚡. Want a metal that withstands 1000°C and weighs like a feather? Set the parameters and the printer does the rest (well, almost).

We are democratizing material design. Now you can dream up specific properties and manufacture them, not the other way around — explains the project leader, probably standing next to a printer that costs more than a house.

The Superpower of On-Demand Alloys

- Unprecedented Precision: Atomic-level control over material composition

- Extreme Properties: Thermal resistance, conductivity, or flexibility on demand

- Circular Economy: Less waste than traditional methods

- Lightning Speed: From screen to reality in a matter of days

The applications are as diverse as they are ambitious: from turbines that don't melt to implants that grow with the patient. Although they still can't print gold (sorry, digital El Dorado seekers) ✨.

So now you know: the future of materials is in downloadable files, not in mines. The 21st-century gold rush might be measured in gigabytes instead of grams 💾🔥.