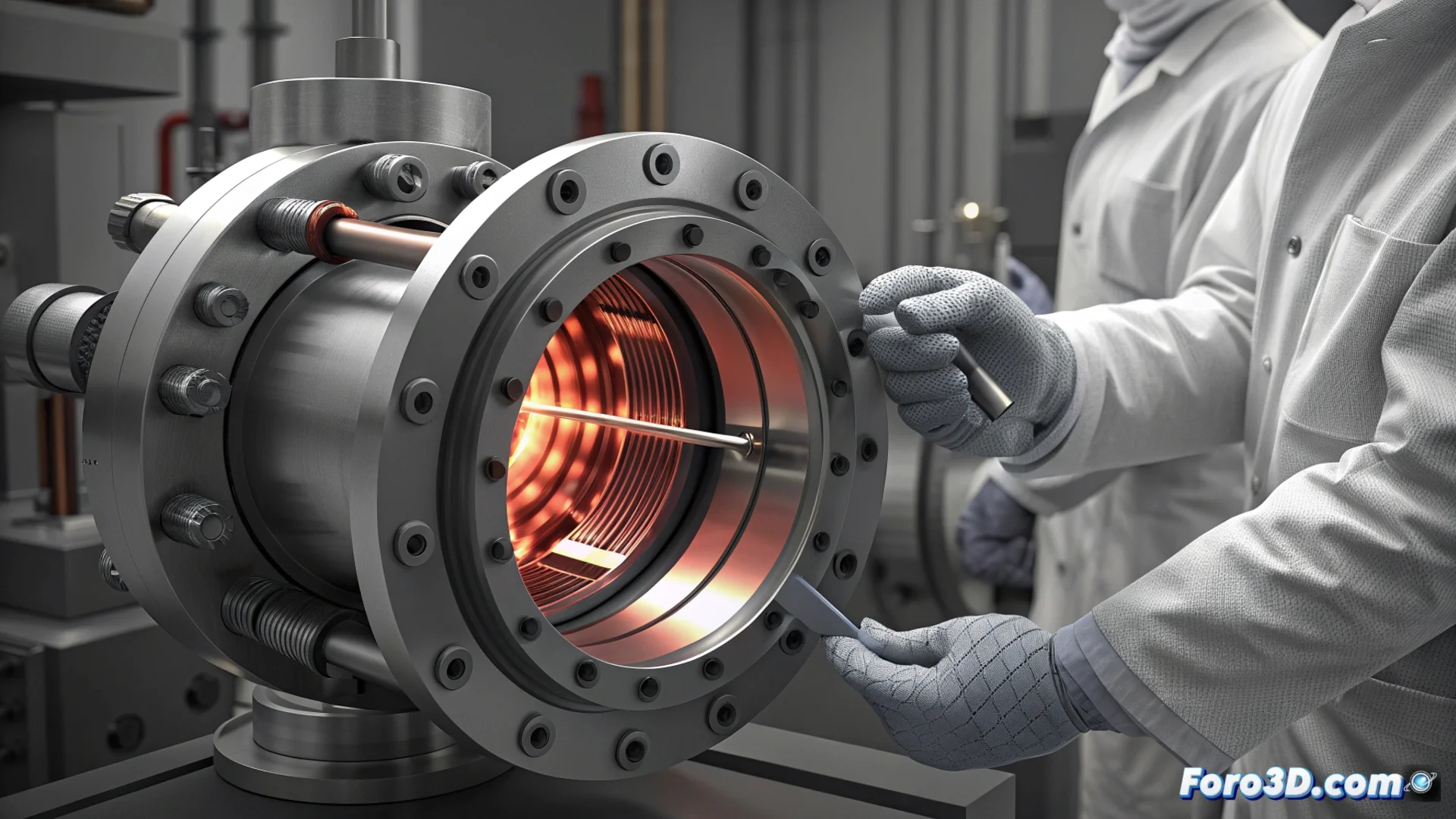

British Researchers Develop Tungsten and Copper for Nuclear Fusion

A team from the University of Manchester is exploring how to produce tungsten and copper parts for fusion reactors. These elements are essential for assembling the divertor, a critical segment that faces immense heat and constant particle impact. The goal is to achieve a robust and permanent bond between the two metals, something that traditional techniques cannot accomplish. To overcome this challenge, the team applies modern additive manufacturing methods. 🔬

Laser 3D Printing Breaks the Barriers of Conventional Processes

Joining tungsten and copper with normal procedures involves major challenges. The disparity in their melting temperatures and how they expand with heat causes stresses that break the joint. Laser 3D printing enables depositing precise layers of copper onto a tungsten base, creating a progressive change. This gradual transition in composition reduces thermal stresses and strengthens the structure of the finished part.

Key advantages of the gradient bond:- Mitigates stresses caused by the different thermal expansion of the metals.

- Creates a stronger interface resistant to fracture.

- Allows designing components with material properties that change in a controlled manner.

Fusion two metals can seem as complex as fusing atoms in a star, but here at least we don't need to replicate solar gravity.

The Progress Aims to Boost Fusion Energy

Achieving an effective and long-lasting divertor is one of the biggest technical challenges for building commercially viable fusion reactors, such as the major ITER project. A component that withstands plasma conditions is essential for the reactor to operate without interruptions. This initiative not only advances materials science but also brings us closer to achieving a clean and nearly unlimited energy source.

Impact on reactor development:- More durable components allow longer and more stable operating cycles.

- Overcomes a key material bottleneck for the design of future reactors.

- The technique could be adapted to join other materials with incompatible properties.

A Crucial Step Toward the Energy Future

This work demonstrates how additive manufacturing solves materials engineering problems that previously seemed insurmountable. By perfecting the bond between tungsten and copper, it paves the way for building the systems that contain fusion plasma. Each advance of this kind brings us a little closer to mastering an energy source that could transform our global electricity supply. ⚡