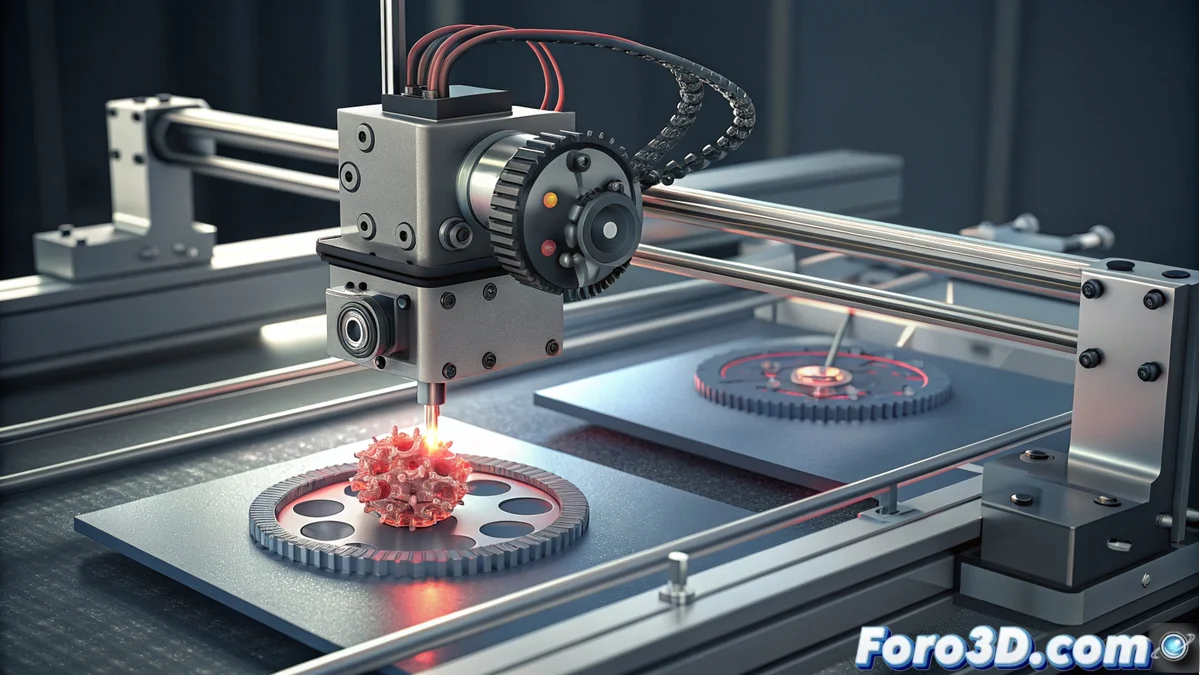

Boston Micro Fabrication Obtains US Patent for Dual-Resolution Micro-Scale 3D Printing System

The company Boston Micro Fabrication has reached a significant technological milestone by receiving US patent number 12,420,486 B2, which legally protects its revolutionary additive manufacturing system in microscopic dimensions. This intellectual property protection specifically covers the dual-resolution architecture integrated into its specialized 3D printing equipment 🎯.

Patented Technological Innovation

The patented system, officially named Multi-Scale System for Projection Micro Stereolithography, represents a fundamental advance in precision manufacturing capabilities. The technology allows users to fluidly alternate between two distinct resolution configurations within the same equipment, completely eliminating the need for manual changes to optical components during the manufacturing process 🔄.

Key Features of the Patented System:- Automatic transition between high and medium resolution modes without operator intervention

- Unified optical architecture that avoids the exchange of physical components

- Maintenance of manufacturing process integrity without technical interruptions

This patent solidifies our leadership position in micro-scale 3D printing and validates years of research into adaptive optical systems for additive manufacturing

Commercial Implementation in the microArch D1025

The dual-resolution technology is already fully operational in the microArch D1025 printer, available on the market since early 2024. This industrial equipment incorporates the patented optical system as the central element of its design, offering users the flexibility to select between 10-micrometer resolutions for ultra-precise details and 25-micrometer resolutions for processes that prioritize production speed ⚡.

Operational Advantages of the microArch D1025:- Continuous workflow without pauses between resolution changes

- Optimization of total manufacturing time according to specific requirements

- Compatibility with specialized materials for advanced technical applications

Specialized Industrial Applications

The system's versatility finds its maximum expression in industrial sectors that simultaneously demand microscopic precision and productive efficiency. Industries such as the manufacturing of implantable medical devices, miniaturized electronic components, integrated photonic systems, and microfluidic devices benefit directly from this ability to adapt resolution according to the specific needs of each zone of the fabricated component 🏭.

Impact on Engineering Processes

Engineers and designers now have a versatile tool that allows them to optimize their manufacturing strategies without compromising the critical details of their designs. While professionals debate the best methodological approaches—whether to start with high resolution and switch to speed or vice versa—the equipment operates with automated efficiency, executing programmed instructions without participating in philosophical considerations about the optimal production approach 🤖.