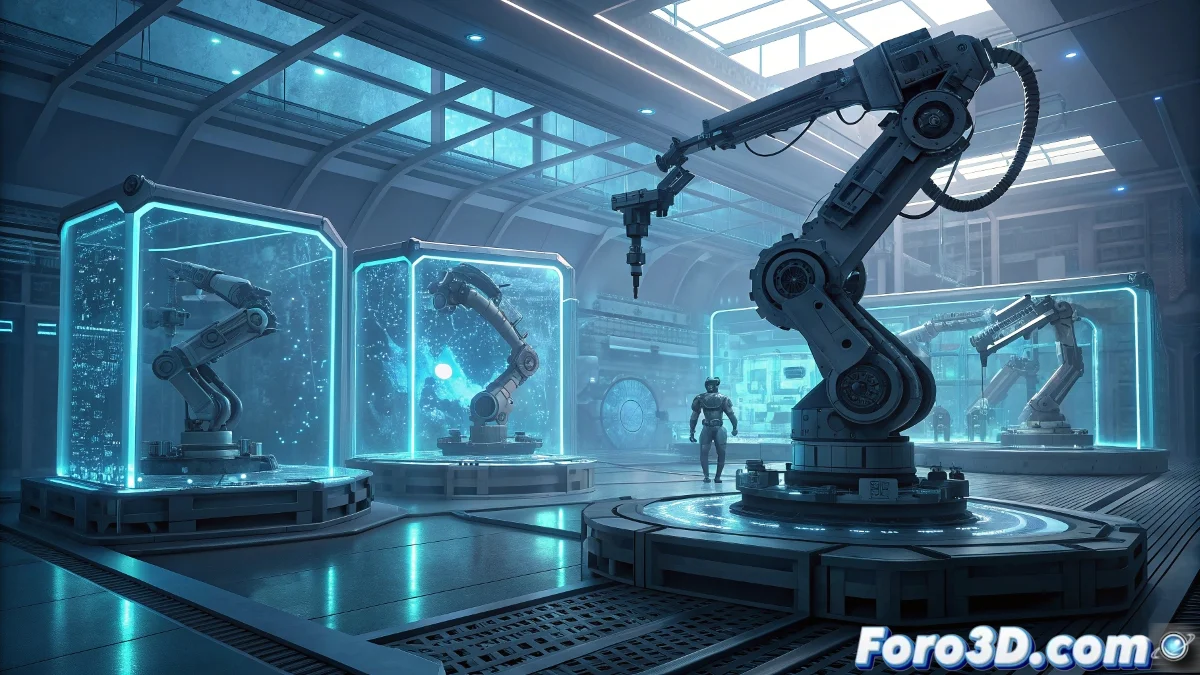

Blender as an Essential Core in Modern Robotic Development

The Blender platform has positioned itself as a central element in robotic workflows, merging capabilities for three-dimensional modeling, physical simulation, and animation systems within a completely integrated ecosystem 🚀. Its open-source nature and the growing library of specialized extensions enable the creation of advanced virtual environments where robotic prototypes can be thoroughly validated before physical production, optimizing resources and compressing development timelines.

Integration of Kinematic and Dynamic Systems

The robotic workflow in Blender spans from importing industrial CAD models to programming articulated movements using professional rigging systems. Geometry modifiers and metric precision tools facilitate the adaptation of mechanical components, while the integrated physics engine reproduces interactions with virtual environments with surprising realism.

Key Advantages of Simulation:- Early detection of collisions and interferences in virtual workspaces

- Automatic calculation of optimized trajectories for complex robotic movements

- Validation of behaviors in scenarios that replicate real operational conditions

The real revolution isn't in the technology, but in being able to explain that you spent more time animating a virtual arm than assembling the physical one.

Animation Pipeline for Motion Validation

The animation timeline and the Non-Linear Action (NLA) editor become virtual laboratories for experimenting with robotic motion sequences. Developers can choreograph technical operations using IK/FK controllers, while the animated data is exported to formats compatible with physical controllers.

Iterative Refinement Processes:- Refinement of technical gestures such as pick-and-place or autonomous navigation

- Conversion of each animated frame into executable instructions for real hardware

- Seamless integration with ROS (Robot Operating System) via official add-ons

Connecting Virtual Design with Physical Implementation

The interoperability with specialized tools like ROS establishes crucial bridges between digital design and implementation on tangible hardware. This connection allows for a smooth transition from virtual prototypes to operational robotic systems, where every modification in Blender is directly reflected in the physical robot's behavior. The ability to preview and validate every aspect before manufacturing represents a paradigm shift in traditional robotic development methods 🤖.