Begner Agenturer installs GEFERTEC's arc80X system in Sweden

The Swedish company Begner Agenturer is accelerating its growth in the manufacturing sector with 3D technology. It confirmed that it will integrate GEFERTEC's arc80X machine into its newly opened facilities in Falun. This move is key to its plan to increase capacity for making metal parts with intricate geometries. 🏭

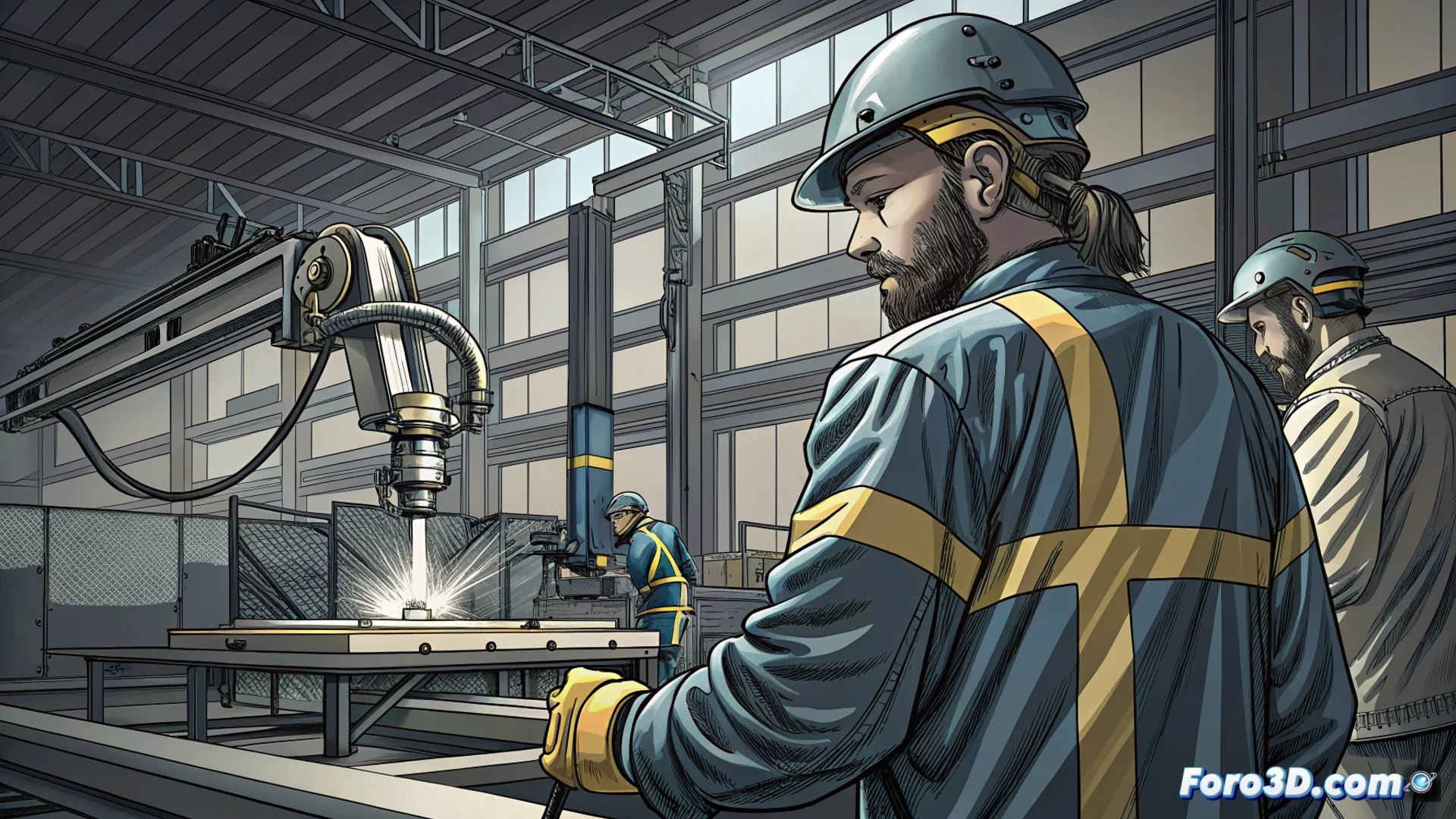

The WAAM technology behind the arc80X

The arc80X equipment operates with the process known as WAAM (Wire Arc Additive Manufacturing). This method melts a metal wire using a high-precision electric arc, depositing material layer by layer to build 3D objects. It stands out for producing large volumes of parts at a faster rate than other metal 3D printing techniques, such as laser sintering. Its main use is to manufacture prototypes, tooling, and operational components in high-demand industries.

Key features of the process:- Uses a controlled electric arc as the energy source to melt the material.

- Utilizes metal wire as raw material, which is usually more economical than powder.

- Ideal for producing large-size parts that would be very costly or impossible to machine.

This technology allows Begner Agenturer to reduce delivery times and offer more flexible solutions to its customers, consolidating its position in the Nordic market.

Strategic objectives at the Falun plant

With this acquisition, the company aims to meet the demand from heavy industries in the region. The Falun plant will specialize in handling orders requiring large-dimension parts or custom designs that are complex to obtain with traditional subtractive methods.

Target sectors and applications:- Aerospace and Defense: For structural components or engines.

- Energy and Oil: Parts for turbines, generators, or drilling equipment.

- Heavy Engineering and Naval: Elements for large machinery or, potentially, ship parts.

The future of manufacturing in Sweden

This installation positions Begner Agenturer as a benchmark in metal additive manufacturing in Scandinavia. The ability to "print" large-scale components opens the door to manufacturing huge parts, such as those needed for a ship, without relying exclusively on a conventional shipyard. The advancement represents a significant change in how critical parts for industry can be produced and supplied. ⚙️