Axial Flux Motors: The Silent Revolution in Electric Supercars

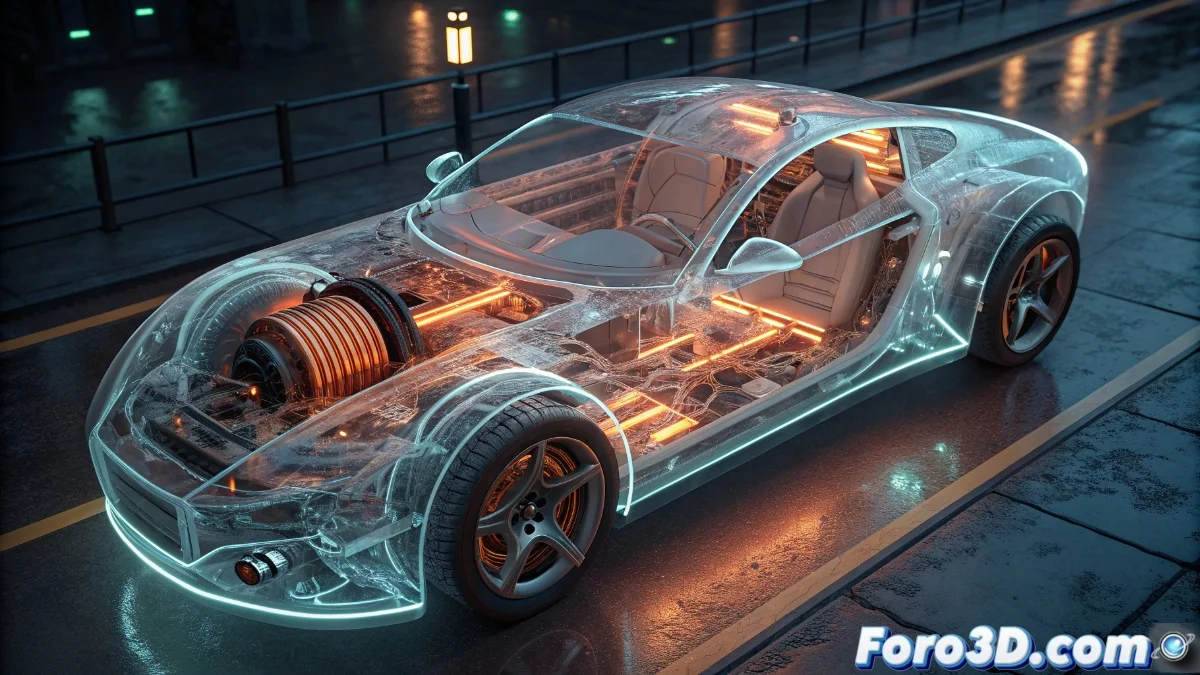

The elite automotive industry is undergoing a radical transformation with the massive adoption of axial flux propulsion systems, a technology that redefines the limits of power and efficiency in ultra-high-performance vehicles. These systems offer a revolutionary torque density in an exceptionally compact format, allowing engineers to create lighter cars with optimized mass distributions. The flat configuration of the motor facilitates innovative implementations, including all-wheel-drive schemes with independent drive units for each tire. 🚗⚡

Technical Advantages of the Axial Architecture

Axial flux motors stand out for their extraordinary power-to-weight ratio, exceeding 95% efficiency under standard operating conditions. Their construction uses permanent magnets and highest-purity copper coils that generate more powerful electromagnetic fields with lower energy demand. This technology enables energy recovery during deceleration that is significantly more effective than traditional systems, extending range in electrified models. The advanced thermal dissipation system prevents overheating even in extreme driving situations.

Key Features:- Energy efficiency superior to 95% under normal operating conditions

- Improved energy recovery during regenerative braking

- Compact design that allows optimizing weight distribution

The extraordinary torque density of these propulsion systems is redefining performance parameters in the elite automotive industry

Implementation in Ultra-Luxury Vehicles

Prestigious manufacturers such as Rimac, Lotus, and Pininfarina are integrating these propulsion systems into their most exclusive models, achieving 0-100 km/h accelerations in times under 2 seconds. The modular nature allows the installation of multiple autonomous drive units, creating all-wheel-drive systems with precise torque vectoring control. This design versatility has inspired concept cars with nearly ideal weight distributions, where the motors are positioned close to the wheels without compromising aerodynamics. Engineers can modify power delivery characteristics through specialized software, adapting the vehicle's behavior to various driving modes.

Highlighted Applications:- 0-100 km/h accelerations in less than 2 seconds

- Modular configuration for all-wheel drive with torque vectoring

- Behavior adaptation through specialized software

The Future of Electric High Performance

It seems that electric supercars have finally found their perfect mechanical ally, although some automotive purists still miss the characteristic roar of combustion engines as their vehicles accelerate in absolute silence toward the future of mobility. This technology represents a turning point in the evolution of high-performance vehicles, combining unprecedented power with revolutionary energy efficiency. 🔋🏎️