Axial Engines: A Rotative Revolution in Propulsion

Axial engines represent an innovative alternative to traditional piston engines, employing a rotative principle that eliminates conventional components such as the crankshaft. This unique architecture promises to revolutionize multiple industries with its compact profile and superior mechanical efficiency 🔄

Fundamental Mechanics of the Rotative System

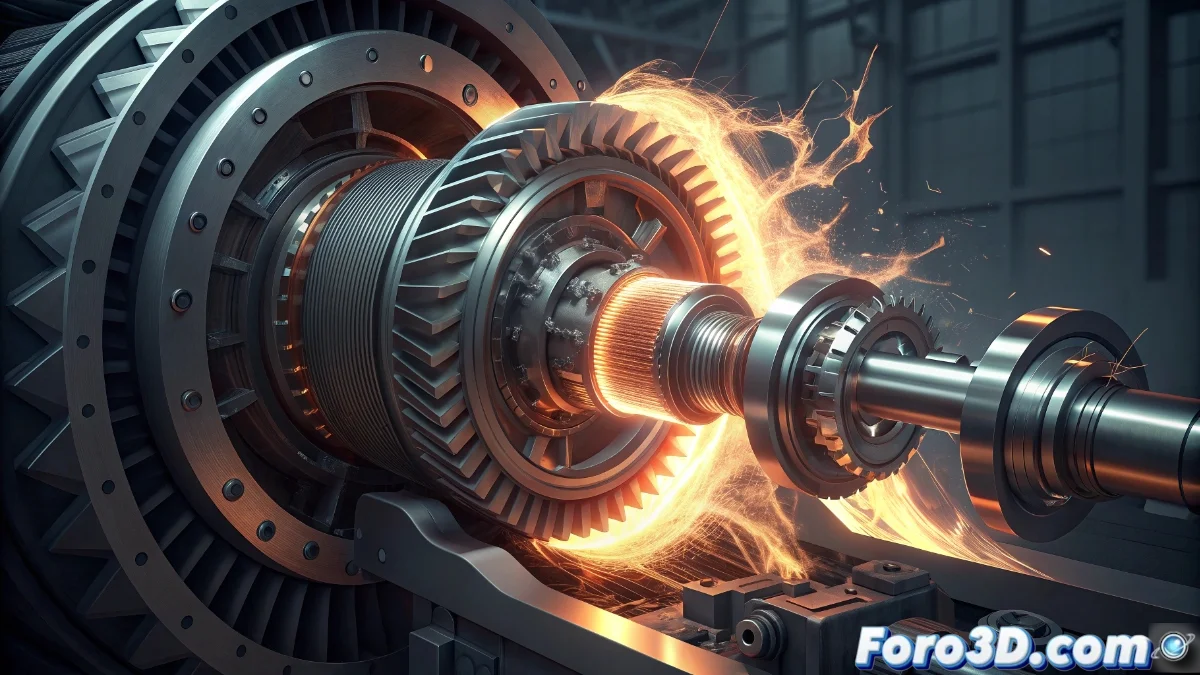

The operational core of these propulsors lies in an eccentric rotor that rotates within a housing of specific geometry, creating variable chambers that execute the complete thermodynamic cycle. The direct transformation of rotative motion into mechanical energy allows for extremely high speeds without conventional reciprocating elements.

Essential Components:- Multilobular rotor that defines the combustion chambers

- Sealing system at the vertices to maintain compression

- Epitrochoidal profile housing that guides the rotary motion

The inherent mechanical simplicity significantly reduces moving parts, but demands ingenious solutions in sealing and cooling

Balance Between Advantages and Practical Limitations

These propulsors stand out for their exceptional power-to-weight ratio and extraordinarily smooth operation, virtues that position them ideally for aerospace applications and portable power systems. However, the technical challenges in material durability and thermal management represent significant obstacles to their mass implementation.

Potential Applications:- Propulsion for drones and unmanned aerial vehicles

- Auxiliary power units in specialized transport

- Compact electrical generation systems

Future Development and Technological Perspectives

The evolutionary path of axial engines critically depends on advances in composite materials and precision manufacturing techniques. Although their development seems to advance in spirals of continuous improvement—a fitting metaphor for their rotative nature—the overcoming of current technical limits could establish them as a viable alternative to conventional propulsors 🚀