Autodesk Fusion 360 Uses Artificial Intelligence to Design and Manufacture Parts

The Autodesk Fusion 360 platform incorporates advanced features that use artificial intelligence to transform how components are conceived and manufactured. These tools allow defining project goals and obtaining optimized design and manufacturing solutions automatically. 🤖

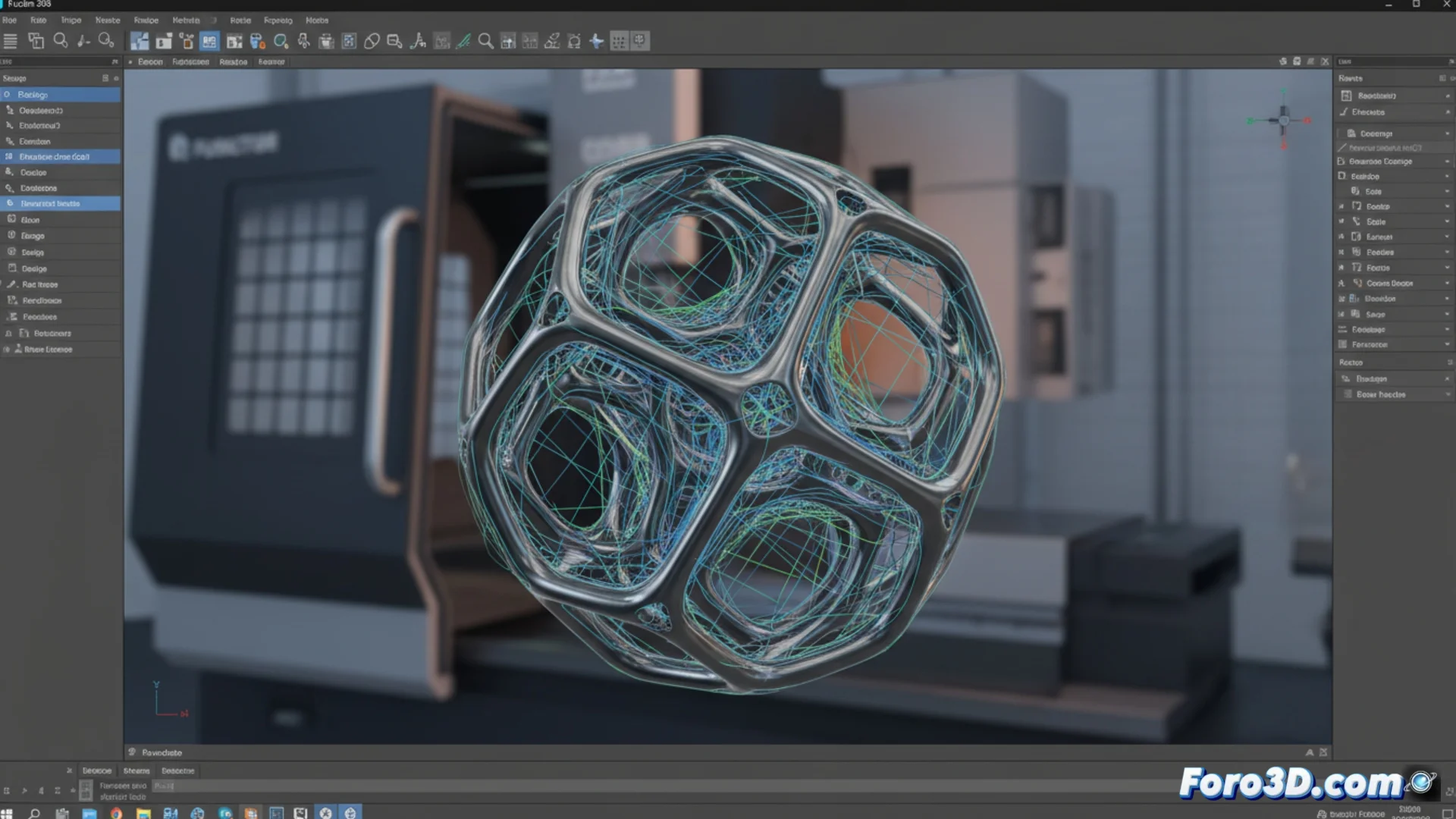

AI Generates Shapes that Meet Engineering Requirements

The user inputs key parameters such as the material, the loads it must withstand, the goal of reducing weight, and the areas that cannot be modified. The generative design system processes this data and proposes multiple geometry options that are both efficient and organic. This method explores possibilities that a designer might overlook, prioritizing effective material use and structural integrity.

Parameters Defined by the User:- The type of material that will be used.

- The specific forces or loads that the part must resist.

- The goal of reducing the final weight of the component.

- The exclusion zones where material cannot be placed.

AI can propose a part so organic and efficient that it resembles an alien bone, and then suggest machining it with a tool that doesn't even exist yet.

Planning Machining with Intelligent Algorithms

Within the CAM module, artificial intelligence examines the created geometry and recommends the most effective way to machine it. It analyzes different toolpaths to select those that shorten the total operation time on the CNC mill. It also considers tool wear by proposing movements that avoid sudden stresses or unnecessary travels.

Advantages of AI-Guided Machining:- Programming faster operations for the CNC machine.

- Extending the lifespan of cutting tools.

- Positively impacting production costs and overall productivity.

A Connected Environment from Concept to Manufacturing

These capabilities operate within a unified environment, making it easy to make changes and test alternatives with great agility. A generated design can be transferred directly to the CAM workspace to organize its manufacturing without losing information. The consistency of the digital model prevents errors when moving from one phase to another. Engineers can modify design constraints, regenerate the shape, and instantly see how that alters the suggested machining strategy, thus closing the complete cycle between imagining a part and preparing to produce it. 🔄