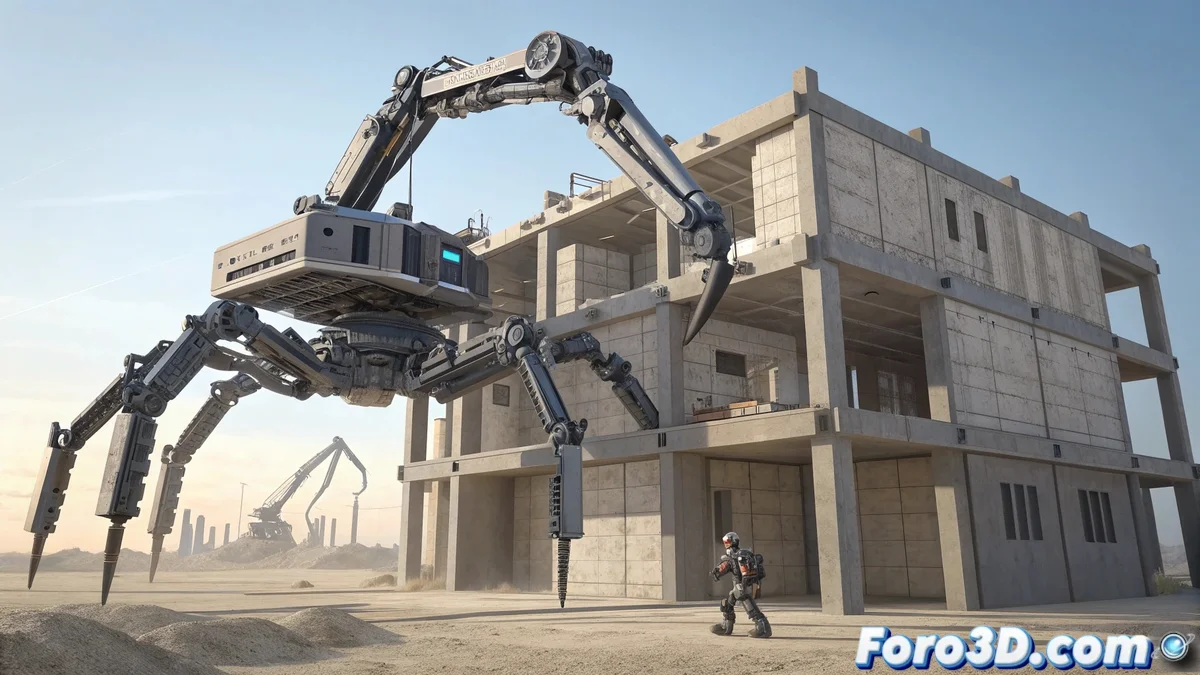

Construction Becomes Arachnid and Digital

An Australian team of engineers has developed what could be the future of construction: a spider-inspired robot capable of printing complete concrete structures in 3D in record time. This innovation combines the advanced mobility of a multi-legged robot with the precision of additive printing, allowing the construction of complete homes in just 24 hours. An evolutionary leap that promises to radically transform one of the industry's most traditional sectors.

Anatomy of a Robotic Builder

The robot features multiple articulated legs that provide exceptional mobility over irregular surfaces and unfinished structures. This unique capability allows it to move over its own work while continuing to print, solving one of the biggest challenges of 3D printing at architectural scale. The system integrates a specialized concrete extrusion head that works coordinated with feedback sensors to maintain precision throughout the construction process.

Integrated Printing Technology

- Multiple articulated legs for omnidirectional mobility

- Extrusion head for fast-drying concrete

- Sensors and cameras for real-time correction

- Integration with BIM software and 3D modeling

Digital to Physical Workflow

The true power of the system lies in its seamless integration with standard design software like Rhino, Autodesk Revit, Blender, and SketchUp. Architects can design complex structures in familiar digital environments and transfer them directly to the robot without needing complex adaptations. This direct connection between the digital model and physical construction eliminates interpretation errors and exponentially accelerates the materialization process.

Applications Beyond Housing

- Emergency construction post-disasters

- Rapid prototyping of architectural elements

- Manufacturing of complex organic structures

- Rehabilitation and expansion of existing buildings

A demonstration of how the convergence between robotics, 3D printing, and digital design can create solutions that seemed like science fiction just a decade ago.

For architects, designers, and construction specialists, this technology represents the materialization of the dream of direct digital manufacturing at architectural scale. The possibility of translating complex 3D models directly into habitable structures without intermediaries could democratize access to customized and efficient housing 🏗️.

And that's how we end up with robots strolling through our future homes while building them... though they'll probably generate fewer complaints about construction delays than human contractors, but more concern about what they'll do when they finish their work 😅.