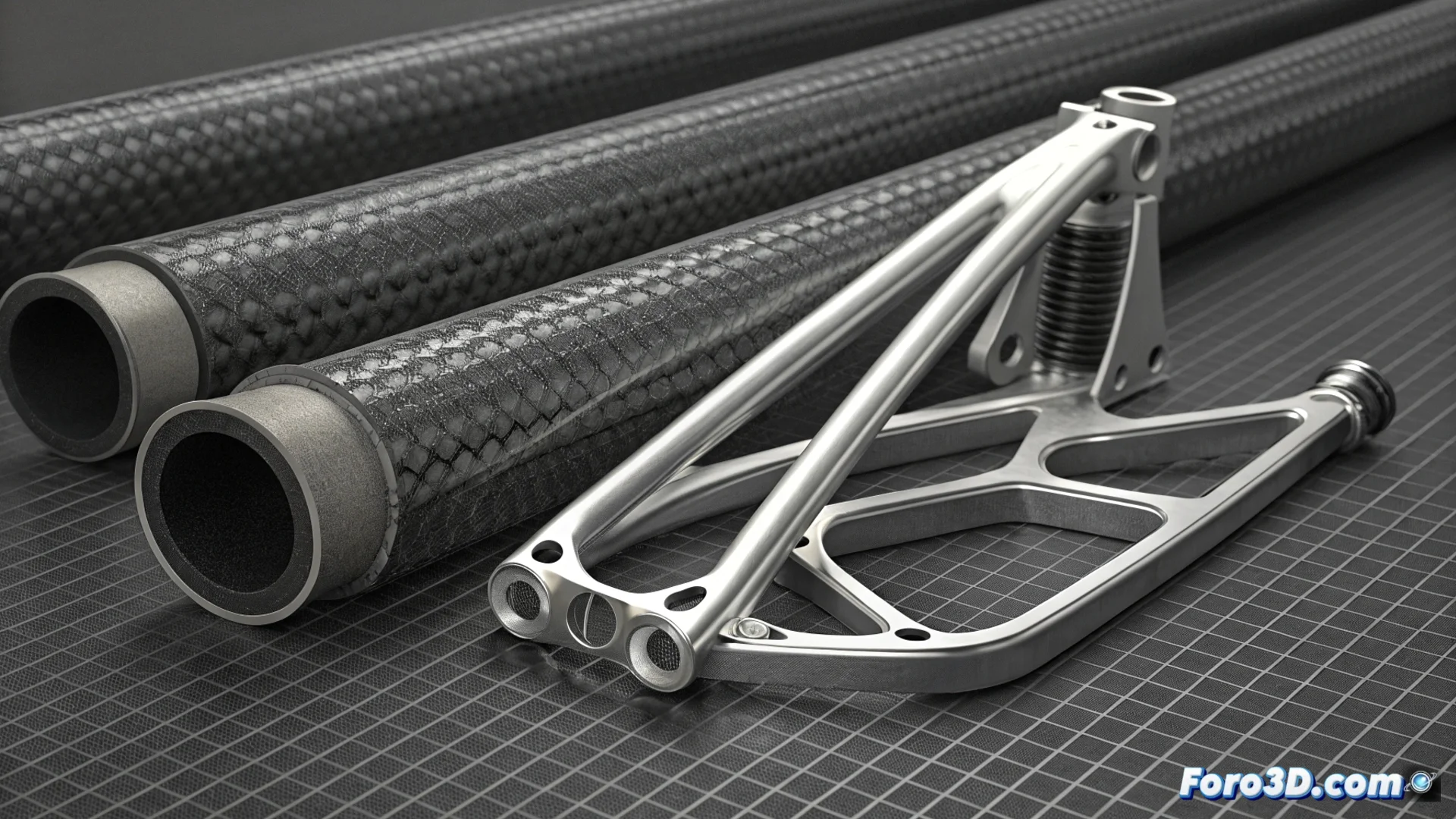

Atherton Bikes Manufactures Frames with 3D-Printed Titanium Lugs

The brand Atherton Bikes, driven by the well-known downhill brothers, is revolutionizing how mountain bikes are produced. Their method integrates 3D-printed titanium lugs with carbon fiber tubes to assemble the frame. This strategy allows customizing each bike to an unprecedented level. 🚵♂️

Customizing Geometry with Additive Manufacturing

Metal 3D printing technology enables the creation of connection components (lugs) with complex internal and external shapes. These parts would be very expensive or impossible to machine with conventional techniques. Each lug serves as a node that joins the carbon tubes forming the main structure of the frame. By printing these nodes, engineers can alter angles, lengths, and joining points so that the frame fits perfectly to the end user's anatomy and pedaling technique.

Key advantages of this system:- Precise morphological fit: The bike adapts to the cyclist's specific measurements.

- Design flexibility: Unique geometries can be tested and produced without high tooling costs.

- Weight and material reduction: 3D printing only deposits titanium where it is structurally necessary.

3D printing gives us the freedom to connect the tubes exactly where we want and how we want, something that is very restrictive with traditional lugs.

Controlling the Frame's Mechanical Behavior

Beyond fitting, this technique allows precisely defining the stiffness of different areas of the frame. Designers can make certain lugs more flexible to absorb vibrations, while others are reinforced to transfer power efficiently. By combining these smart lugs with selected carbon tubes, a predictable and optimized dynamic behavior is achieved for downhill and pedaling performance.

Performance objectives achieved:- Efficient power response: The frame minimizes energy loss when pedaling.

- Controlled vibration absorption: Terrain fatigue is filtered without compromising handling precision.

- Improved durability: 3D-printed titanium and carbon form an extremely strong joint.

The Future of Custom Frames

Atherton Bikes' approach demonstrates how additive manufacturing can transform an industry. It's not just about producing, but about developing tailored solutions that directly respond to the experience accumulated by elite athletes. Although the shipping process for such a specialized frame always carries risks, the inherent robustness of the titanium lugs suggests that the design is prepared to withstand more than just the rigors of the mountain. 🛡️