Artificial Photosynthesis: Creating Green Hydrogen with Solar Light

In the global search for sustainable energy sources, a technology inspired by nature stands out for its elegance and potential: artificial photosynthesis. This innovative field does not aim to generate sugars, like plants do, but clean fuels, mainly hydrogen, using only sunlight, water, and specialized catalysts. This green hydrogen is positioned as a key piece to decarbonize those sectors where direct electrification is complex, such as aviation, maritime transport, or steelmaking. The dream of truly circular and emission-free energy takes shape through chemistry ⚗️.

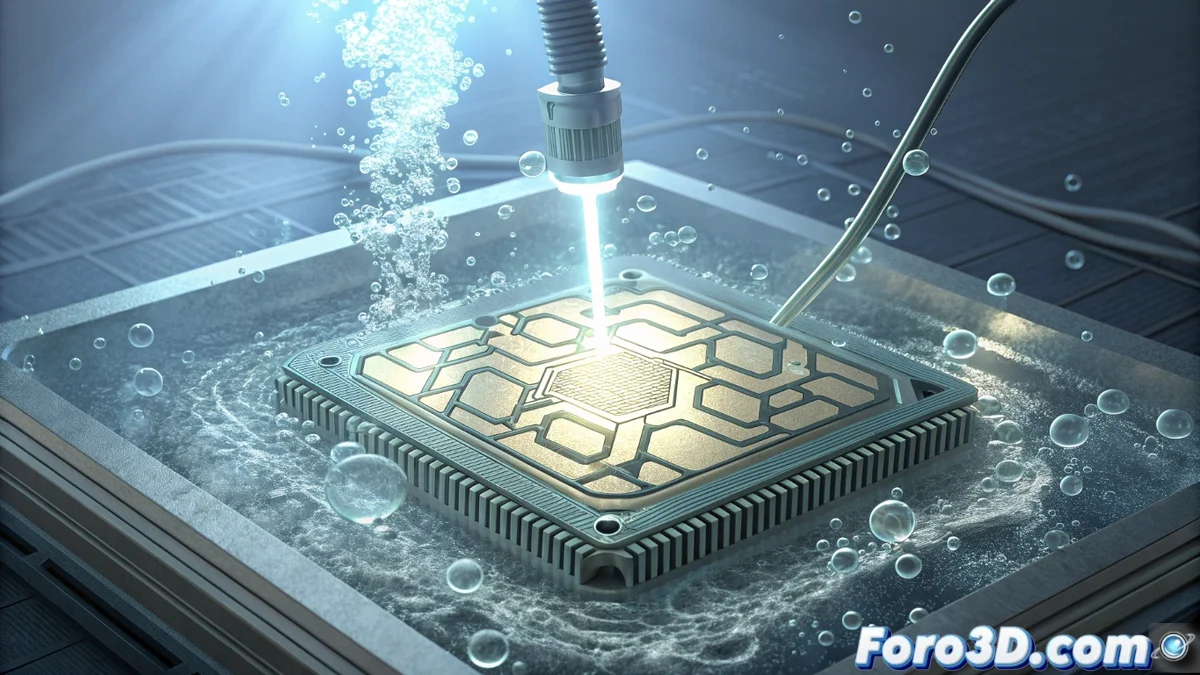

The Inner Workings of Artificial Leaves

The core of this technology is artificial photosystems, devices commonly nicknamed artificial leaves. Unlike a conventional solar panel that produces electricity, these systems integrate semiconductor materials that absorb photons and, in combination with molecular catalysts (often based on abundant metals like cobalt, nickel, or iron), drive a direct chemical reaction. When submerged in water and exposed to light, the semiconductor excites electrical charges that travel to the catalysts. There, the stable bonds of the water molecule (H₂O) are broken, releasing hydrogen gas (H₂) on one side and oxygen (O₂) on the other, in a process that emulates the efficiency of natural photosynthesis 🌿.

Key Components of an Artificial Photosystem:- Light Absorber: A semiconductor material (such as silicon or metal oxides) that captures solar energy and generates electron-hole pairs.

- Hydrogen Evolution Catalyst (HER): Accelerates the reduction reaction that combines protons (H⁺) and electrons to form H₂ gas.

- Oxygen Evolution Catalyst (OER): Manages the more complex oxidation reaction that separates oxygen from water. It is often the bottleneck in efficiency.

The goal is not to have a bush in the garden that fills the tank, but to create industrial solar farms that produce fuel on a massive and sustainable scale.

Obstacles on the Path to Industrialization

Despite its enormous promise, the transition from laboratories to large-scale applications presents considerable technical challenges. The solar-to-fuel conversion efficiency (STF) still needs to improve to compete economically. Additionally, the long-term stability of materials in aqueous and often corrosive environments is a critical issue. Researchers are focusing on designing more robust photoelectrochemical cells and discovering catalysts that are both highly active, durable, and composed of abundant earthly elements 🔬.

Main Lines of Research to Overcome Challenges:- Monolithic Integration: Develop devices where the light absorber and catalysts are fused into a single compact and efficient unit.

- New Materials: Explore perovskites, nitrides, or powder photocatalysts that offer better cost-performance ratios.

- System Design: Optimize the management of produced gases (H₂ and O₂) to avoid explosive mixtures and maximize fuel collection.

The Horizon: Solar Hydrogen Farms

The visionary future of this technology involves the creation of solar hydrogen farms. Vast expanses of these devices are imagined working in parallel, possibly on water surfaces or in deserts, capturing solar energy to produce green hydrogen continuously. This fuel could then be stored, transported, and used in fuel cells to generate clean electricity on demand or directly in industrial processes. Although the path is long, advances in materials science and engineering bring the reality of a truly sustainable, sun-powered hydrogen economy ever closer ☀️➡️💧➡️🚀.