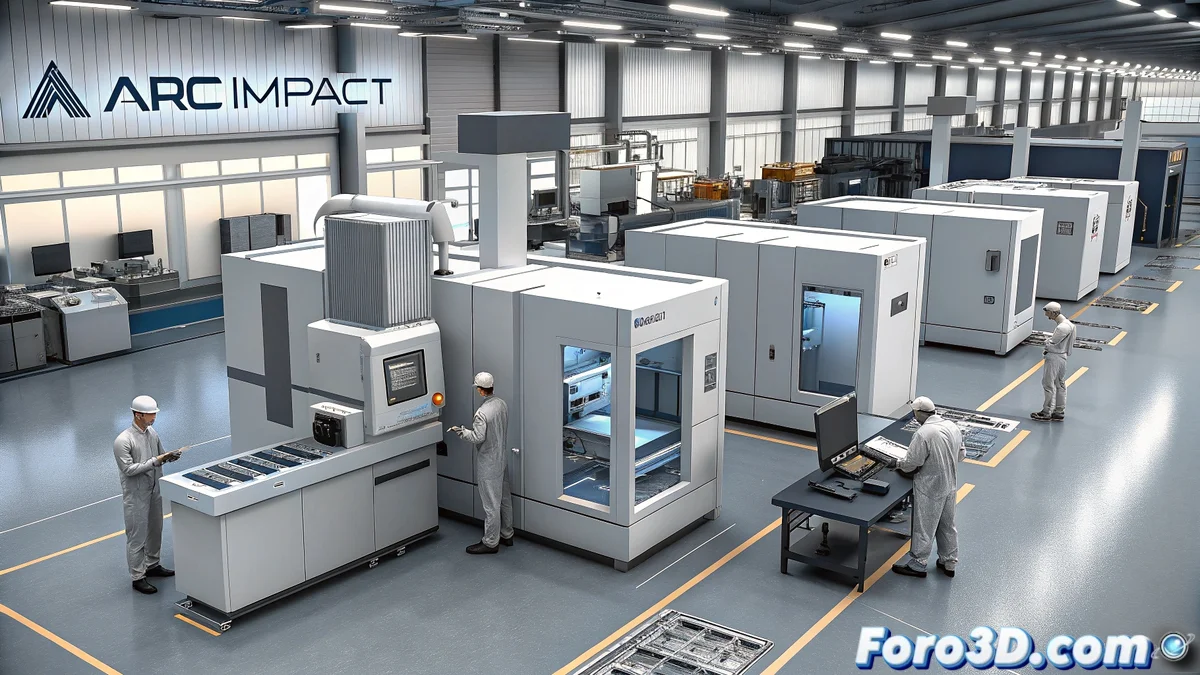

Arc Impact Strengthens Its Platform with Desktop Metal Asset Acquisition

Arc Impact Acquisition Corporation has announced the acquisition of selected assets from Desktop Metal, Inc., including metal and ceramic 3D printing systems, as well as materials from Adaptive3D 🏭. This strategic purchase will allow Arc Impact to consolidate an artificial intelligence-driven advanced manufacturing platform, focused on critical sectors such as defense, automotive, aerospace, and medical. The integration of these technologies not only optimizes production processes but also accelerates innovation in materials and design, positioning the company at the forefront of American reindustrialization. Because in the digital age, even the most complex manufacturing becomes intelligent 💡.

Acquired Technologies and Their Impact on Advanced Manufacturing

The acquisition includes Desktop Metal's Binder Jet portfolio, which encompasses the Production System and the X-Series, known for their ability to produce end-use metal and ceramic components with high precision and scalability. Additionally, Adaptive3D's DuraChain elastomers and FreeFoam resins are incorporated, ideal for applications requiring flexibility and strength in polymers. These technologies are complemented by AI simulations and digital twins, allowing for the optimization of designs and processes before physical manufacturing. The result: reduced waste, greater efficiency, and lighter, more durable components 🚀.

These technologies enable the production of end-use components in metal, ceramic, and polymers, optimizing processes through AI simulations and digital twins.

Strategic Applications in Defense and Medicine

Arc Impact already collaborates with key players in high-demand sectors. With the U.S. Army DEVCOM, it works on qualifying binder-jet printed aluminum for defense applications, ensuring components meet rigorous military standards. With Northrop Grumman, it develops silicon carbide parts for aerospace systems. In the medical field, the company manufactures customized components through DLP printing, such as prosthetics and implants, demonstrating the versatility of its platform in applications where precision and customization are critical. Additive manufacturing thus becomes a pillar for cross-sector innovation 🏥.

Future Vision and Arc Impact's Goals

The company aims to accelerate materials research and process optimization, reducing development times and increasing production scalability. The integration of AI not only improves efficiency but also enables the prediction of failures and real-time parameter adjustments, minimizing errors and costs. Arc Impact positions itself as an emerging leader in the reindustrialization of the United States, focusing on the production of advanced components to replace imports and strengthen strategic autonomy in sensitive sectors. The future of manufacturing is intelligent, agile, and local 🌐.

Technical Features of the Platform

Arc Impact's platform incorporates several key technologies:

- Binder Jet Printing: For metals and ceramics with high productivity and resolution.

- Adaptive3D Materials: Elastomers and resins for flexible, high-performance applications.

- AI Simulation: Optimization of designs and processes using predictive algorithms.

- Digital Twins: Virtual replicas for testing and continuous improvement.

The Irony of Hyper-Advanced Manufacturing

With so much 3D printing and AI technology, engineers will soon need personal drones to pick up parts printed in seconds... though coffee will still take the same time to brew ☕.