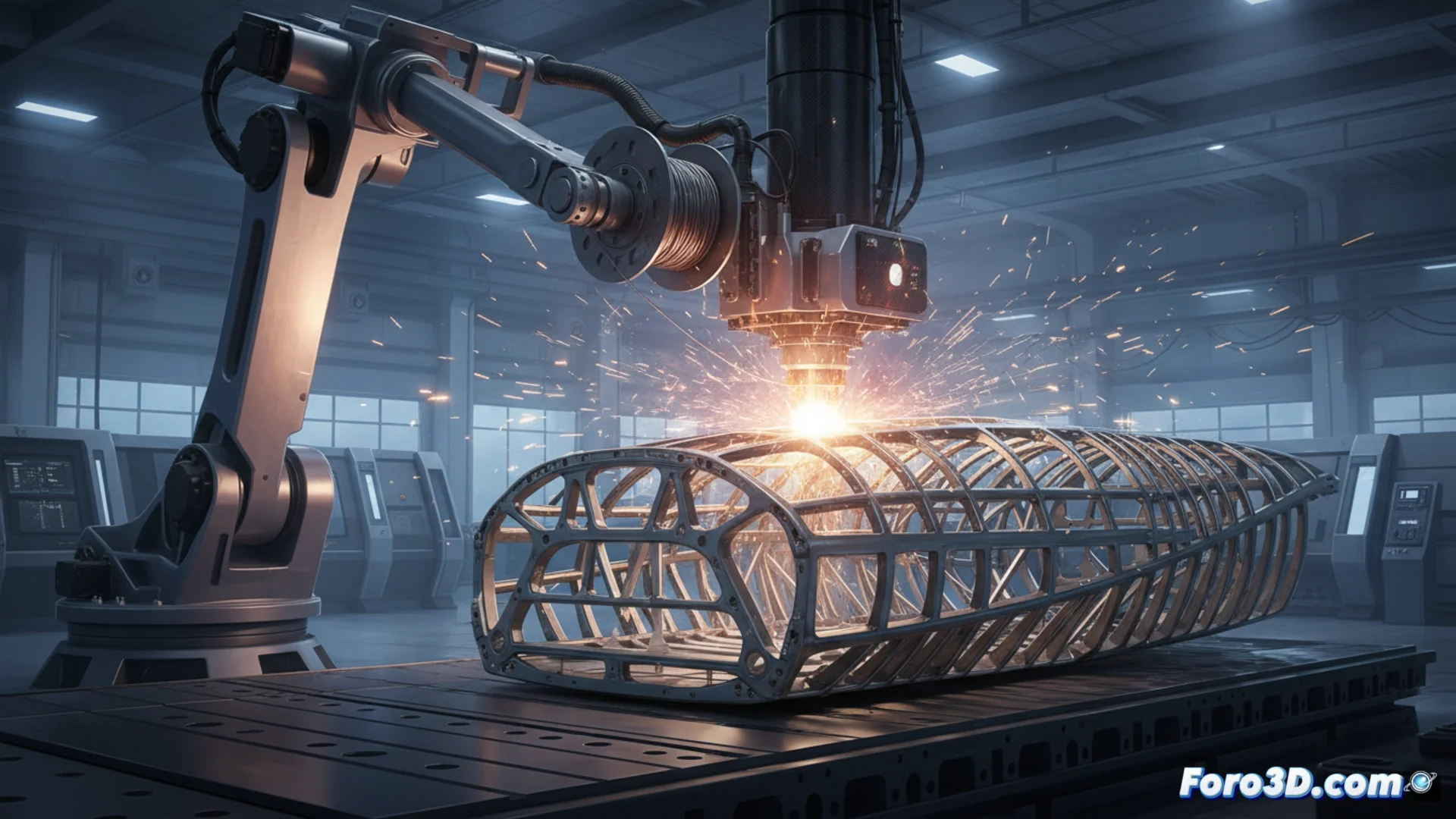

Airbus Manufactures Large Titanium Parts with Wire-DED Technology

The aeronautical company Airbus is applying an advanced additive manufacturing method to produce large-sized titanium structural components. This technique, known as wire-DED, represents a significant advancement in how the largest parts of an aircraft are built. 🛩️

The Layer-by-Layer Manufacturing Process

The wire-DED system works by depositing material selectively. It uses a titanium wire that is melted with a high-power energy source, such as a laser, plasma, or electron beam. This allows building parts up to seven meters long directly from a digital model, with geometry very close to the final one.

Key Advantages of the Wire-DED Method:- Drastically reduces wasted material compared to traditional subtractive methods.

- Accelerates the total time to produce a component, from design to raw part.

- Minimizes the need to forge the metal and machine it extensively afterward.

CNC machining, which once dominated the workshop, now shares space with a machine that essentially draws with molten metal.

Implementation in Aircraft like the A350

This technology is no longer a prototype. Airbus has successfully integrated parts manufactured with wire-DED into in-service aircraft. A concrete example is the cargo door frames of the A350 model. These components still go through a final machining phase and a rigorous certification process, but their use demonstrates the technique's viability in real environments.

Next Steps and Expansion:- The company plans to extend the use of this technique to other areas of the aircraft.

- The goal is to further optimize assembly lines and simplify complex designs.

- It seeks to redesign parts to make them lighter or with previously impossible internal shapes.

Transforming the Aerospace Industry

This evolution marks a profound change in the production of large structural parts. By depositing material only where required, an efficiency is achieved that traditional methods cannot match. This directly impacts cost and time, but also opens the door to reinventing how components are designed. The near future will see this technology gain more prominence, building the aeronautical revolution, literally, line by line. ⚙️