AFRL and University of Michigan Develop 3D-Printed Structures That Efficiently Block Vibrations

Vibration engineering reaches new levels of sophistication with the development of 3D-printed structures specifically designed to block mechanical waves. This research collaboration between the Air Force and academia represents a significant advance in protecting sensitive equipment 🛡️.

Computational Designs for Advanced Vibration Control

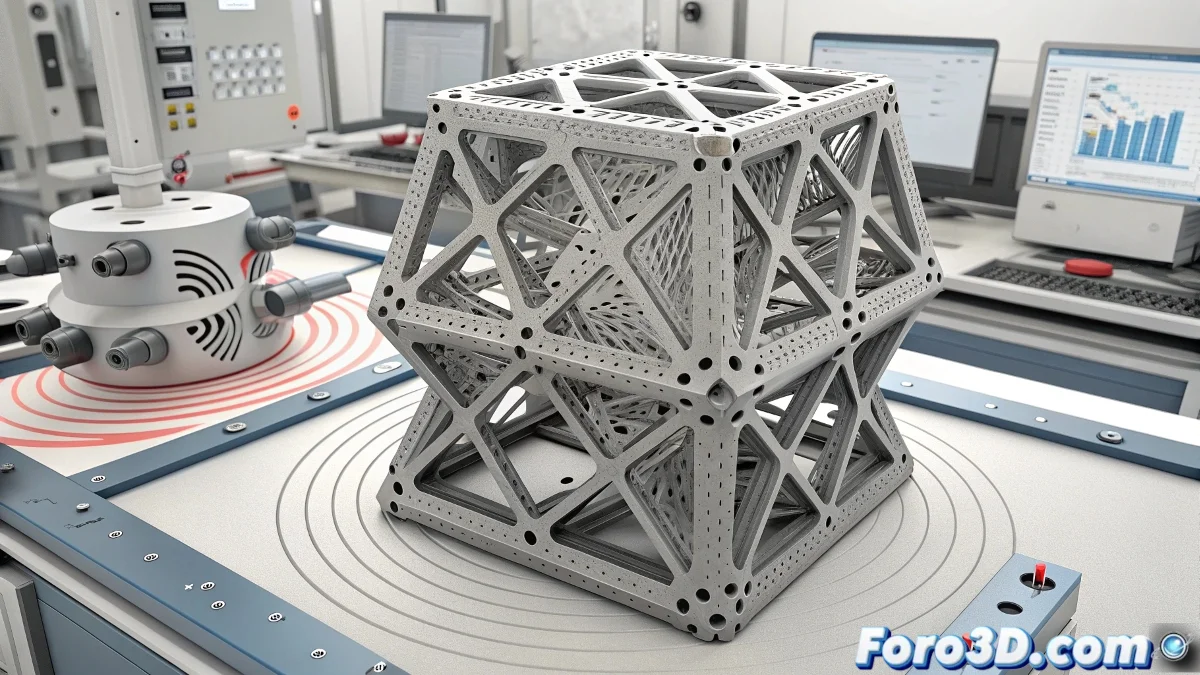

Researchers have used topology optimization algorithms to create geometries that efficiently scatter and absorb vibrations. These metamaterial designs leverage the unique capabilities of additive manufacturing to produce structures impossible to fabricate conventionally.

Innovative Technical Features:- Geometries with local resonators tuned to specific frequencies

- Cellular structures with damping integrated into the design

- Fractal patterns that scatter vibrational energy across multiple scales

3D printing allows us to go beyond traditional manufacturing limitations and create structures that literally redirect and absorb vibrational energy in a programmed manner

Critical Applications in High-Precision Industries

The technology finds immediate applications in sectors where vibrations compromise performance or safety. From aerospace systems to medical instrumentation, these structures offer customized protection against different vibrational profiles ✈️.

Priority Implementation Fields:- Navigation and guidance systems in aerospace vehicles

- Sensor platforms for defense and surveillance applications

- Critical automotive components in high-performance vehicles

Competitive Advantages of Additive Manufacturing

3D printing not only enables the creation of complex geometries but also optimizes material usage and reduces the weight of damping solutions. This comprehensive approach radically transforms the traditional focus of vibration control in advanced engineering 🏭.