Innovations in Additive Manufacturing Materials

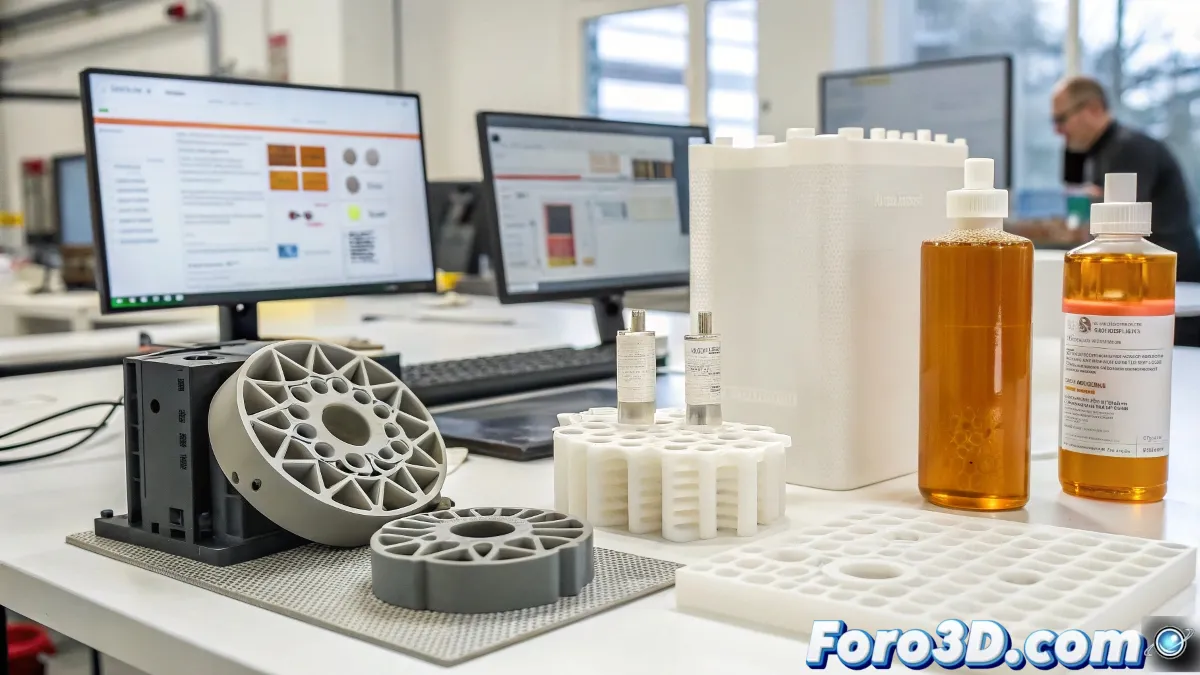

The professional 3D printing sector is experiencing significant advances in the development of materials with enhanced mechanical properties. These improvements allow parts manufactured using additive technologies to compete in performance with components produced by traditional methods.

"The evolution of 3D printing materials is removing the barriers between prototyping and final production"

Improvements in High-Performance Resins

The latest generation of resins for SLA printing presents notable characteristics:

- Impact resistance comparable to industrial thermoplastics

- Greater deformation capacity before fracturing

- Dimensional stability under demanding working conditions

- Compatibility with accelerated post-processing procedures

Optimization of Curing Processes

The new post-processing systems considerably reduce the time needed to achieve the final properties of the parts:

- Rapid heating to optimal temperature

- Uniformity in the curing of complex parts

- Greater energy efficiency

- Ability to process multiple materials

Integration with Industrial Workflows

Software updates allow for better resource management in production environments:

- Centralized control of multiple machines

- Automation of repetitive processes

- Compatibility with traditional manufacturing systems

- Tools for serial production

Future Perspectives

These developments are transforming the role of 3D printing in industry, enabling its use not only for rapid prototyping but also for final applications in sectors such as:

- Automotive components

- Medical devices

- Industrial tools

- Consumer products