Researchers from the Lawrence Livermore National Laboratory and various universities have achieved a key breakthrough in the field of 3D metal printing. Thanks to a new method, complex materials such as copper and tungsten have been optimized, opening new possibilities for different industries.

The Challenge of Working with Complex Metals

One of the main challenges in 3D printing with metals like copper is their ability to reflect laser energy, which reduces the efficiency of the process. In traditional terms, this phenomenon increases energy consumption, making the process less efficient and more costly.

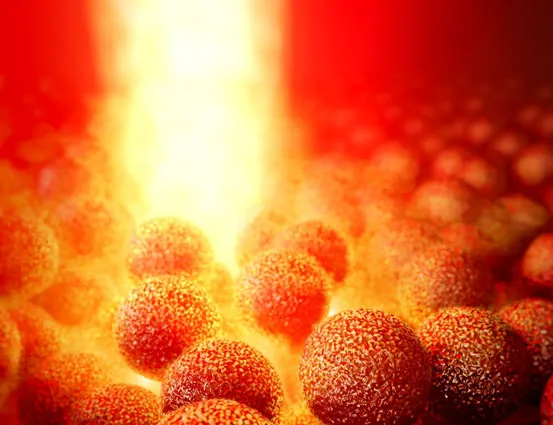

An Innovative Solution: Wet Chemical Etching

The research team has developed a process called wet chemical etching, which involves submerging metal powders in a special solution that gives them a texture at the nanometric level. This texture facilitates energy absorption by the material, increasing the efficiency of the 3D printing process.

“The new process improves energy absorption by up to 70%, significantly reducing costs and the energy required during the printing of metals like copper or tungsten.”

Benefits for Industry

- Energy Efficiency: By reducing energy consumption, the printing process becomes more sustainable and cost-effective.

- Accessibility: The technique does not require customized machines, making it more accessible to various industrial sectors.

- High Precision: Thanks to this advance, printed parts are more precise, improving their performance in high-demand applications.

- Cost Reduction: By improving efficiency and reducing energy use, production costs are considerably lowered.

Environmental and Economic Impact

The improvement in energy efficiency not only offers economic benefits but also reduces the environmental impact of 3D printing by requiring fewer resources to produce the same high-quality parts. This is particularly relevant for industries such as heat exchanger manufacturing or clean energy technologies, which could leverage these innovations to optimize their processes.

The Future of 3D Metal Printing

This advance in 3D printing of complex metals, such as copper and tungsten, allows companies from various sectors to manufacture high-performance parts with greater precision, lower energy consumption, and reduced costs. Thanks to this technique, 3D metal printing becomes a more viable, accessible, and sustainable option for the future.

“The combination of efficiency and sustainability opens new opportunities for industries that require high-quality parts with low environmental impact.”

With this innovative technology, 3D metal printing is expected to continue its expansion and become an essential tool for industrial sectors worldwide.