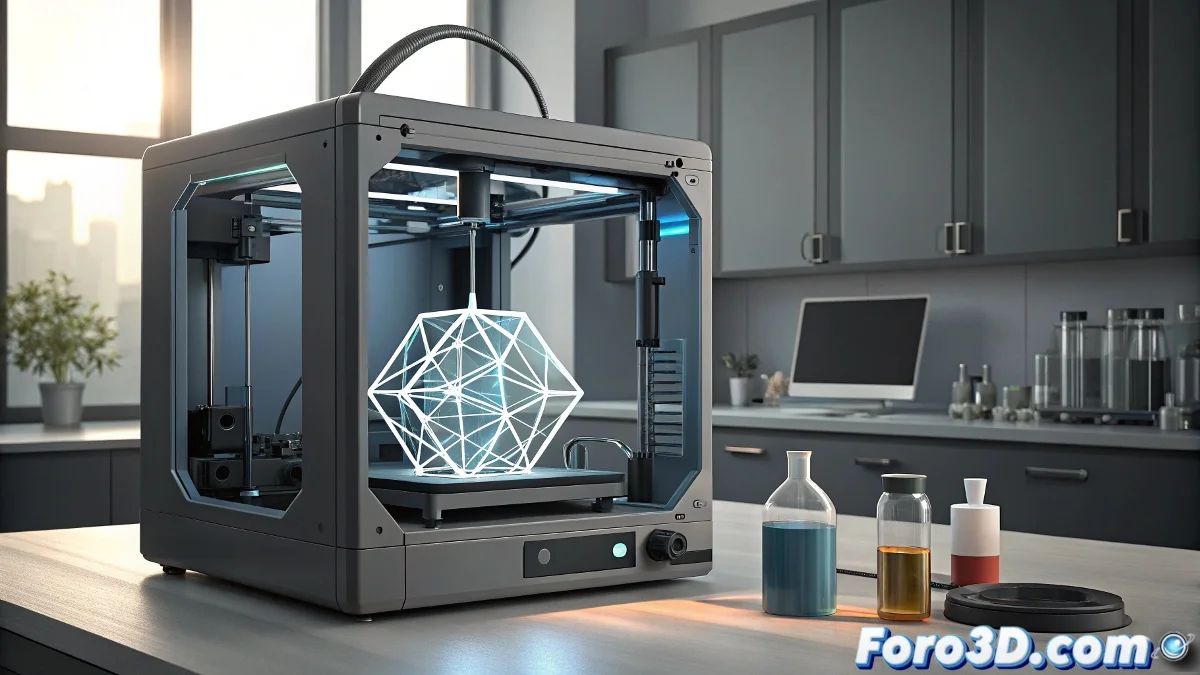

Advanced Maintenance for 3D Printers with DLS Technology

The arrival of 3D printers with DLS technology has marked a before and after in additive manufacturing, standing out for its revolutionary printing speed. However, this technological innovation brings new challenges in post-print maintenance, especially in resin handling and system cleaning. Users must adapt to specific procedures to avoid waste and maximize efficiency 🚀.

Innovative Tank Cleaning Techniques

The continuous light system requires a different approach for cleaning the resin container. Experts emphasize the use of specialized silicone spatulas that preserve the tank's integrity. An increasingly widespread practice is the immediate filtering of leftover resin after each print, using fine mesh filters to remove impurities. This filtered material must be stored in opaque and airtight containers to maintain its properties.

Efficient Cleaning Strategies:- Implementation of dual interchangeable tank systems to reduce downtime between prints

- Use of silicone spatulas that avoid scratches and damage to the container surface

- Systematic filtering of leftover resin with high-precision meshes for reuse

The user community is revolutionizing maintenance with collaborative solutions that optimize every step of the process

Material Performance Maximization

Reducing resin waste is essential for economic and environmental sustainability. Through the use of specialized software, users can precisely calculate the volume needed for each project, incorporating material optimization functions. Manufacturers are responding with innovative developments such as resin cartridges with vacuum systems that eliminate air bubbles and facilitate the near-total return of leftover material.

Advanced Utilization Methods:- Precise volume calculation using software with integrated optimization algorithms

- Implementation of vacuum cartridges that minimize losses and bubbles

- Open sharing of parameter configurations that reduce excess without compromising quality

Adapting to the New Era of 3D Printing

What seemed like a liberating technology has evolved into a process that requires specialized knowledge. Users must develop skills in resin management and predictive maintenance to make the most of their equipment. The learning curve, although demanding, is being facilitated by community collaboration and the development of increasingly intuitive tools. The future of DLS 3D printing will depend on this balance between technological innovation and accessible maintenance practices 💡.