Additive Manufacturing Transforms Auxiliary Power Unit Production in Aviation

The Auxiliary Power Unit (APU) is a small turbine engine, crucial for generating electrical and pneumatic power on an aircraft when the main engines are off. Leading companies like Honeywell are now implementing additive manufacturing to produce the most intricate parts of these systems. This technology redefines design limits, enabling the creation of internal channels and cavities that are unfeasible with conventional machining, dramatically optimizing airflow and heat management. ✈️

Redesigning Critical Components Layer by Layer

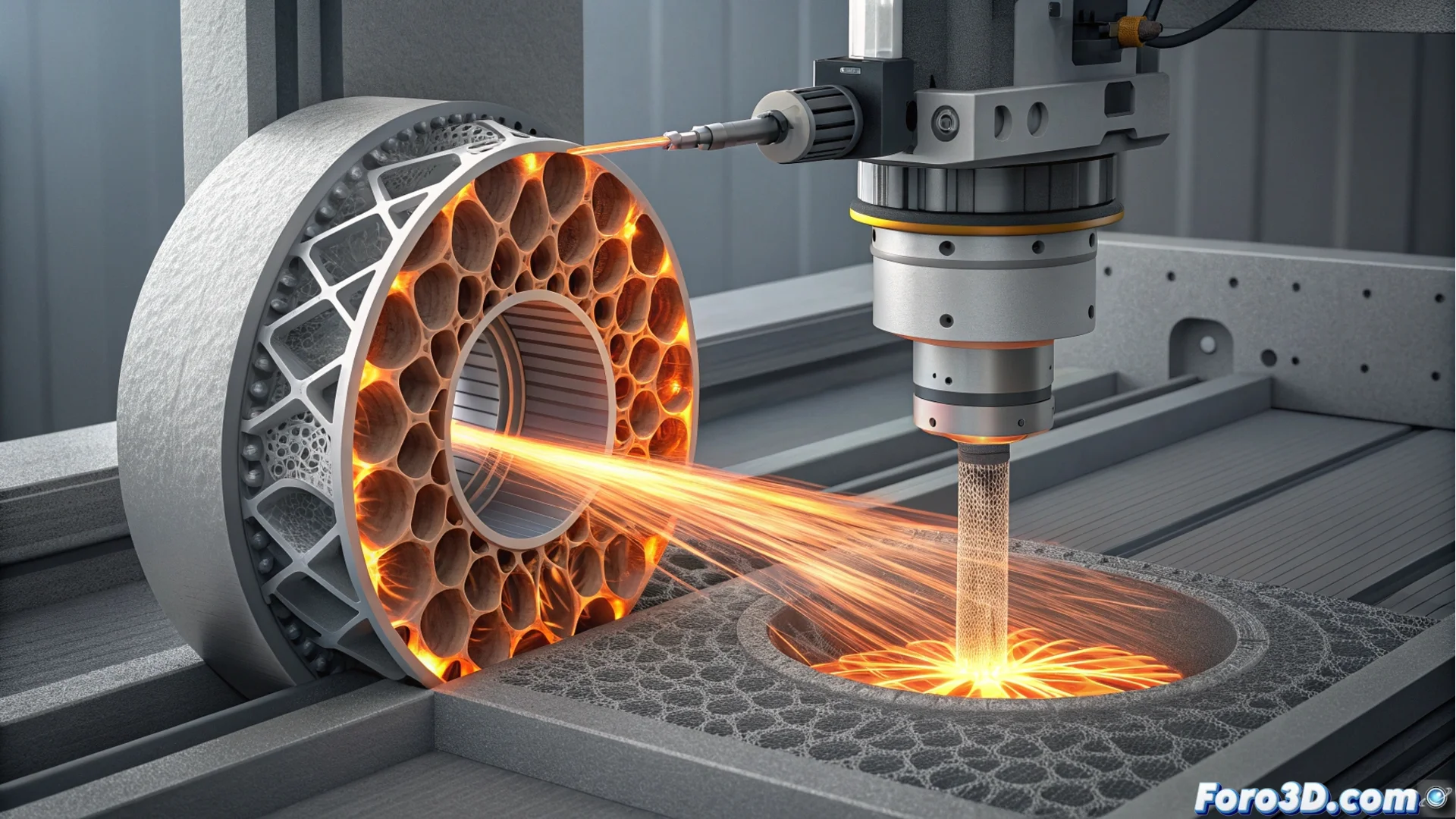

Key elements such as combustion chambers and turbine blades are 3D printed. These are typically produced in high-performance nickel or cobalt alloys, using processes like laser powder bed fusion (LPBF). By building the part additively, organic and unified geometries are achieved that are lighter and have fewer welded or bolted joints. This not only lightens the final assembly but also simplifies assembly of the auxiliary engine, reducing time and costs.

Key Advantages of Integrating Parts:- Reduce Failure Points: Consolidating multiple parts into a single monolithic component eliminates joints and minimizes places where cracks can initiate.

- Shorten Supply Chains: Fewer suppliers for subassembled components are needed, streamlining logistics.

- Design Freedom: Engineers can design the interior of components so that fuel mixes and burns more efficiently, improving overall performance.

The geometric freedom offered by additive manufacturing allows optimizing airflow and heat transfer in levels that were previously science fiction for auxiliary engines.

Tangible Impact on Efficiency and Reliability

These design improvements translate directly into an auxiliary engine that consumes less fuel and is notably more reliable throughout its operational life. The ability to manufacture on demand with fewer production steps also significantly accelerates the process of producing these engines, better responding to market needs.

Final Operational Benefits:- Improve Thermal Performance and combustion efficiency.

- Produce Components with shorter lead times and less material waste.

- Obtain APU Engines with longer time between overhauls and less maintenance.

A Present Reality in Modern Aviation

Although it may seem like cutting-edge innovation, it is a well-established reality in the industry. It is very likely that the plane you travel on uses additively manufactured parts in its APU for essential functions, such as keeping electrical systems and air conditioning operational before takeoff. Additive manufacturing has ceased to be a future promise to become a fundamental pillar for producing smarter and more efficient aerospace components. 🛫