Additive manufacturing revolutionizes hydraulic infrastructures

3D printing is profoundly changing the methods for building and maintaining water distribution networks. This technology enables on-demand manufacturing of complex components, such as custom valves or conduits with advanced internal shapes that improve flow. Delivery times are shortened and stock storage costs are reduced, as only the necessary parts are produced near where they are installed. This accelerates repair and expansion tasks for infrastructures, especially in remote locations where obtaining spare parts with traditional methods is slow and expensive. 🚰

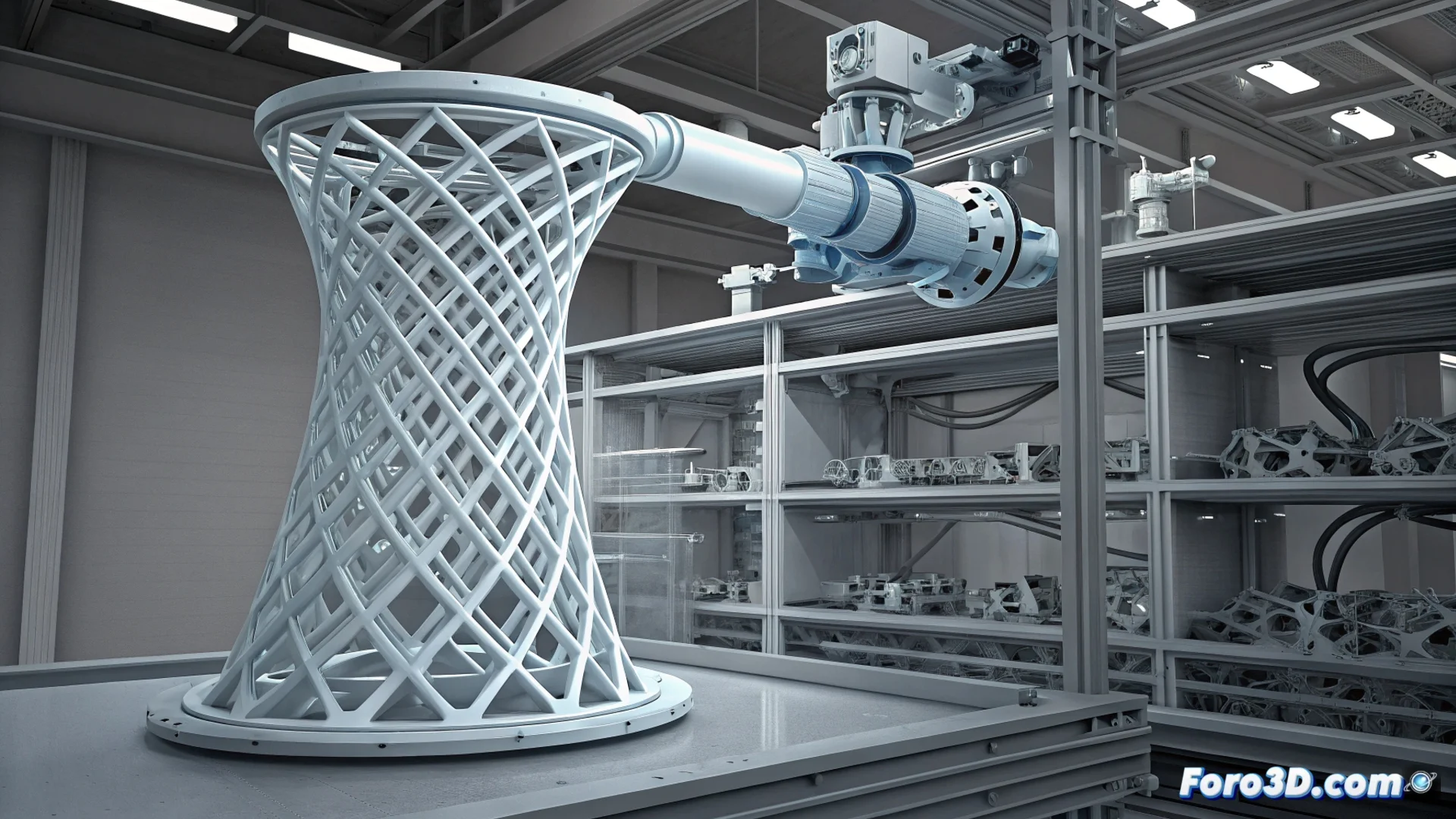

Customize parts to boost efficiency

Engineers can now design elements that were previously unfeasible to produce. They develop nozzles for irrigation that dose water precisely, filters with defined porosities, and couplings that prevent leaks. By printing with corrosion-resistant polymers or composite materials, the lifespan of parts exposed to chemicals or hostile environments is extended. This flexibility to adapt each design to its specific function increases the performance of the entire hydraulic system.

Key advantages of customization:- Optimized geometries: Create internal channels that reduce friction and improve water flow.

- Specific materials: Use composites or technical plastics that resist abrasion and chemicals.

- Perfect fit: Manufacture connectors and adapters to the exact measure of old or non-standard installations.

The ability to iterate quickly on a physical design shortens the development cycles for smarter hydraulic solutions.

Innovate quickly and sustainably

Additive manufacturing facilitates prototyping and validating new concepts in an agile and cost-effective way. Research teams test and adjust tangible models to create more effective systems that combat pollution or capture water resources. Additionally, this process generates less waste than subtractive techniques (like machining), because it only deposits material where needed. Some initiatives are even investigating printing with recycled materials, promoting a circular economy model in water management.

Impact on development and the environment:- Agile prototyping: Test and modify component designs in hours or days, not weeks.

- Less waste: In contrast to milling or turning, where large amounts of excess material are removed and discarded.

- Circular economy: Explore the use of recycled plastics as filament for printing non-critical parts.

A paradigm shift in maintenance

This approach transforms the reactive logic of infrastructure maintenance. Instead of relying on long supply chains and large warehouses, the ability to produce locally any critical part drastically reduces network downtime. The true innovation lies in being able to respond to a breakdown with a digital file and a 3D printer, ensuring service continuity in a previously unthinkable way. 🔧