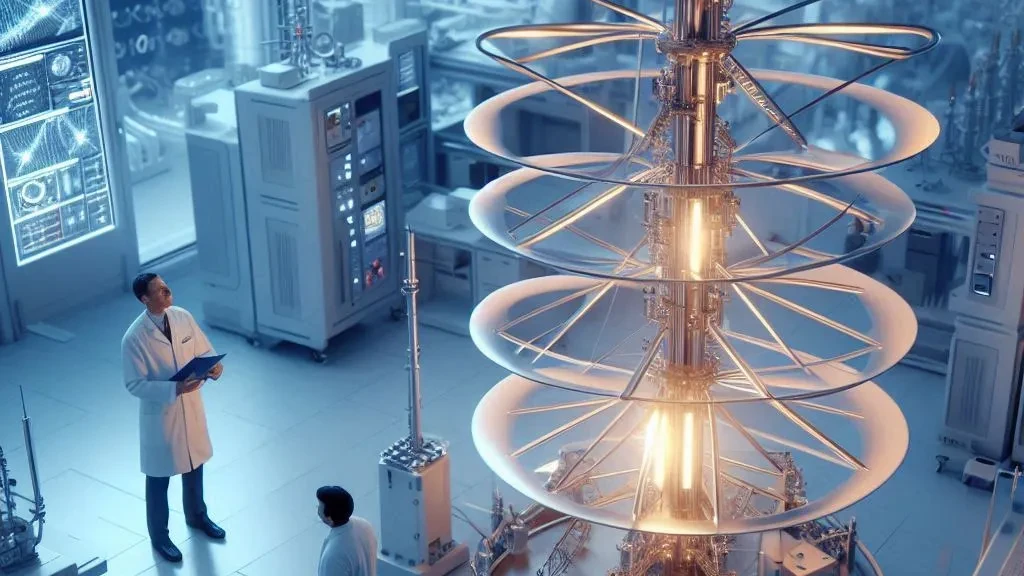

A team of researchers from the Johns Hopkins University Applied Physics Laboratory has developed a revolutionary antenna capable of changing shape based on temperature. This breakthrough is achieved using 3D printing and shape memory alloys like nitinol, allowing the antenna to adapt to different operating frequencies. In this way, it replaces multiple fixed antennas, providing a much more flexible and efficient solution for various technological applications.

Operation and Applications of the Adaptable Antenna

This antenna's ability to change its structure in real-time according to environmental conditions represents a significant leap in telecommunications. By being able to adapt to different frequencies, the antenna optimizes data transmission based on the situation, improving connectivity in a wide range of environments.

The potential applications of this technology span sectors such as:

- Telecommunications: Improvement of signal coverage and quality in hard-to-reach areas or areas with dynamic frequency changes.

- Defense: Adaptability for missions requiring mobile and flexible communication equipment.

- Space Exploration: Adaptation to the changing conditions of space to maintain constant and efficient communication.

Development and Overcome Challenges

The project, which began in 2019, has overcome numerous technical challenges related to integrating 3D printing with advanced materials like nitinol, which has the ability to "remember" its original shape. This innovative combination has enabled the creation of an antenna that is not only efficient but also adaptable in real-time, something that was not previously possible with traditional antennas.

"The adaptable antenna is not only a technological advancement but also a demonstration of the power of additive manufacturing to transform key sectors like telecommunications and defense."

Implications for the Future of Technology

This advancement has the potential to revolutionize the design and production of communication devices, making technology more flexible and efficient. As additive manufacturing continues to advance, we are likely to see more applications of this type of technology in various fields, from medicine to aerospace engineering.

In summary, the adaptable antenna developed by the Johns Hopkins researchers is an example of how innovation in materials and manufacturing techniques can lead to more efficient and versatile solutions, opening new possibilities for the future of telecommunications and space exploration.