Accelerated Wear in Voron Printers Due to High Speed

Voron printers stand out for their ability to operate at very high speeds. However, maintaining constant accelerations above 15,000 mm/s² can compromise their mechanical integrity in the medium term. This intensive use does not usually cause sudden failure, but rather progressive deterioration that directly affects the final quality of the parts. 🛠️

Recognizing Signs of Fatigue in Components

The first warning is usually unusual sounds, such as squeaks or vibrations, coming from the linear motion carriages. Subsequently, the machine begins to lose precision, which manifests as layers that do not align correctly, surfaces with vibration patterns, or imperfections in the corners of the models.

Steps to Confirm the Diagnosis:- Listen carefully to detect anomalous noises during printing.

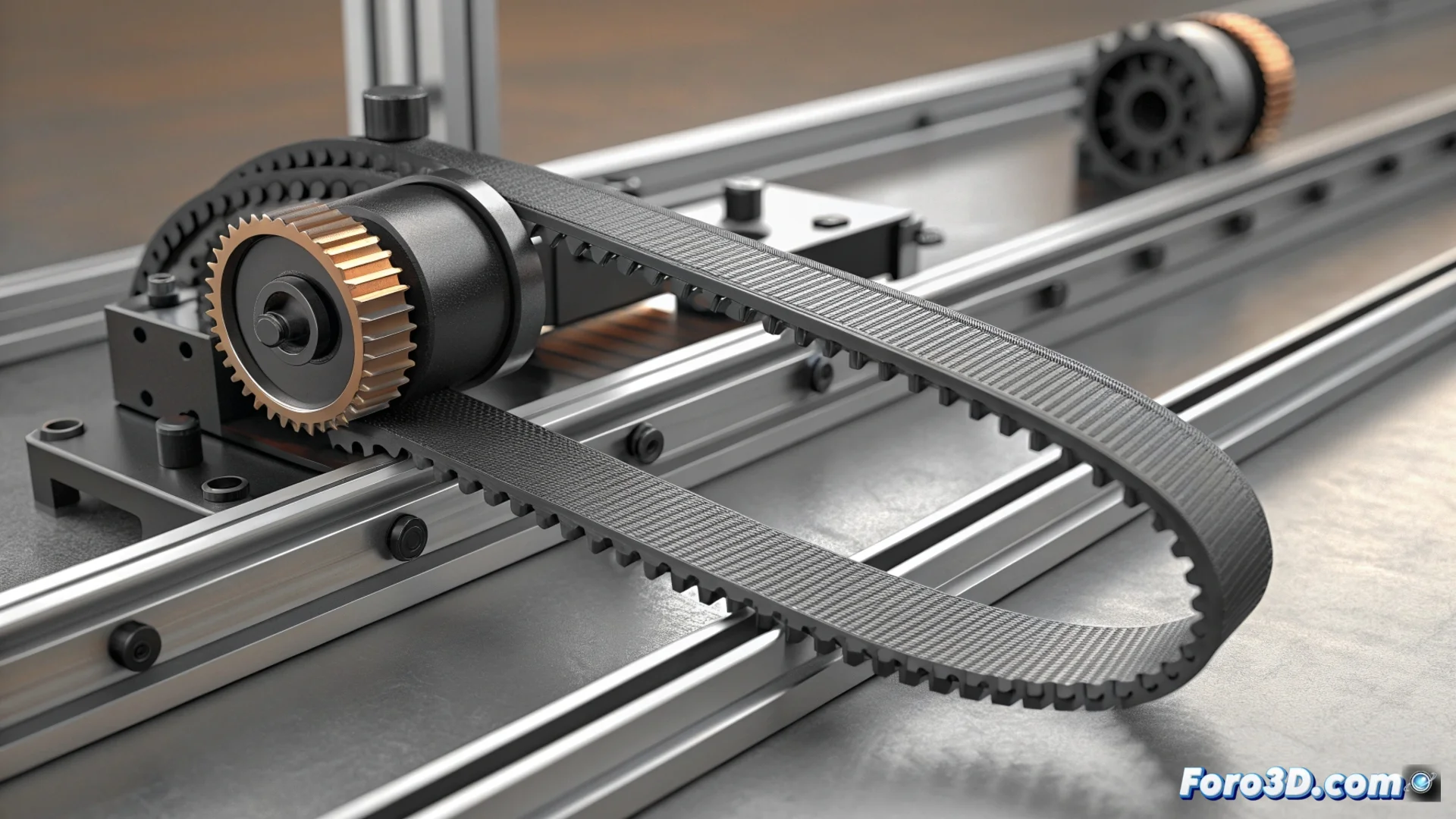

- Visually inspect the transmission belts for worn teeth, loose fibers, or excessive stretching.

- Manually check the linear bearings to assess if they have play or if their movement is not smooth.

The paradox of building a machine to run and then having to moderate its pace so it doesn't fall apart has its point. Sometimes, maximum speed does not equate to optimal efficiency.

Implementing Effective Preventive Maintenance

To counteract this premature wear, it is essential to establish a routine of periodic care. This proactive approach not only mitigates deterioration but can significantly extend the printer's operational life, even under high-demand conditions.

Key Maintenance Actions:- Frequently clean and lubricate the linear rails and bearings.

- Adjust belt tension according to the manufacturer's specifications.

- Inspect pulleys to ensure they are secure on their shafts and have no play.

- Consider using higher-quality components, such as polymer-coated bearings or fiberglass-reinforced belts, for intensive use environments.

Balancing Performance and Durability

Managing a Voron printer for high speed involves finding a balance. Prioritizing durability through rigorous maintenance and the selection of robust components allows enjoying high performance without sacrificing long-term print quality consistency. The key is understanding that caring for mechanical elements is the foundation for reliable production.