AAMC Certifies EOS Metal 3D Printing Technology for Critical Aircraft Parts

The aerospace industry reaches a fundamental regulatory milestone with the AAMC certification of EOS's metal 3D printing technology. This official validation sets a crucial precedent for the mass adoption of additive manufacturing in safety-critical applications ✈️.

Rigorous Aeronautical Certification Standards

The AAMC certification confirms that EOS's processes meet the most demanding requirements of the aeronautical industry. This comprehensive validation covers not only the final mechanical properties but the entire production cycle, from materials to quality control.

Key Certified Aspects:- Quality control of metallic raw materials and powder batches

- Stability and repeatability of batch printing processes

- Complete traceability of each part through digital documentation

This certification marks a turning point where additive manufacturing ceases to be an emerging technology to become an established production solution for critical components

Competitive Advantages in Aeronautical Production

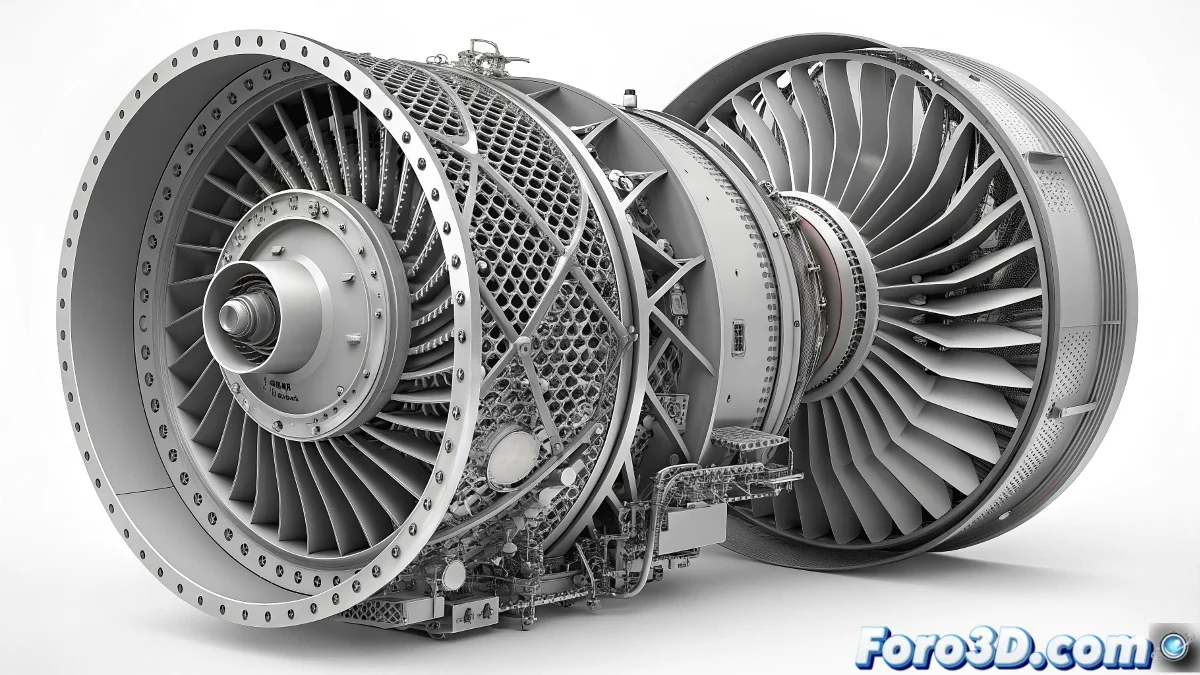

The certified technology enables significant optimizations in design and manufacturing that surpass the capabilities of traditional methods. The geometric freedom of metal 3D printing facilitates the creation of optimized structures that reduce weight without compromising strength 🏭.

Now Certified Components:- Structural supports with optimized topology

- Mounting systems and brackets for avionics

- Hydraulic and pneumatic system components

Future of Additive Manufacturing in Aviation

This historic certification not only validates the current technology but paves the way for more ambitious applications in engines, control systems, and primary structures. Regulatory confidence accelerates the transition towards digital manufacturing across the entire global aerospace industry 🚀.