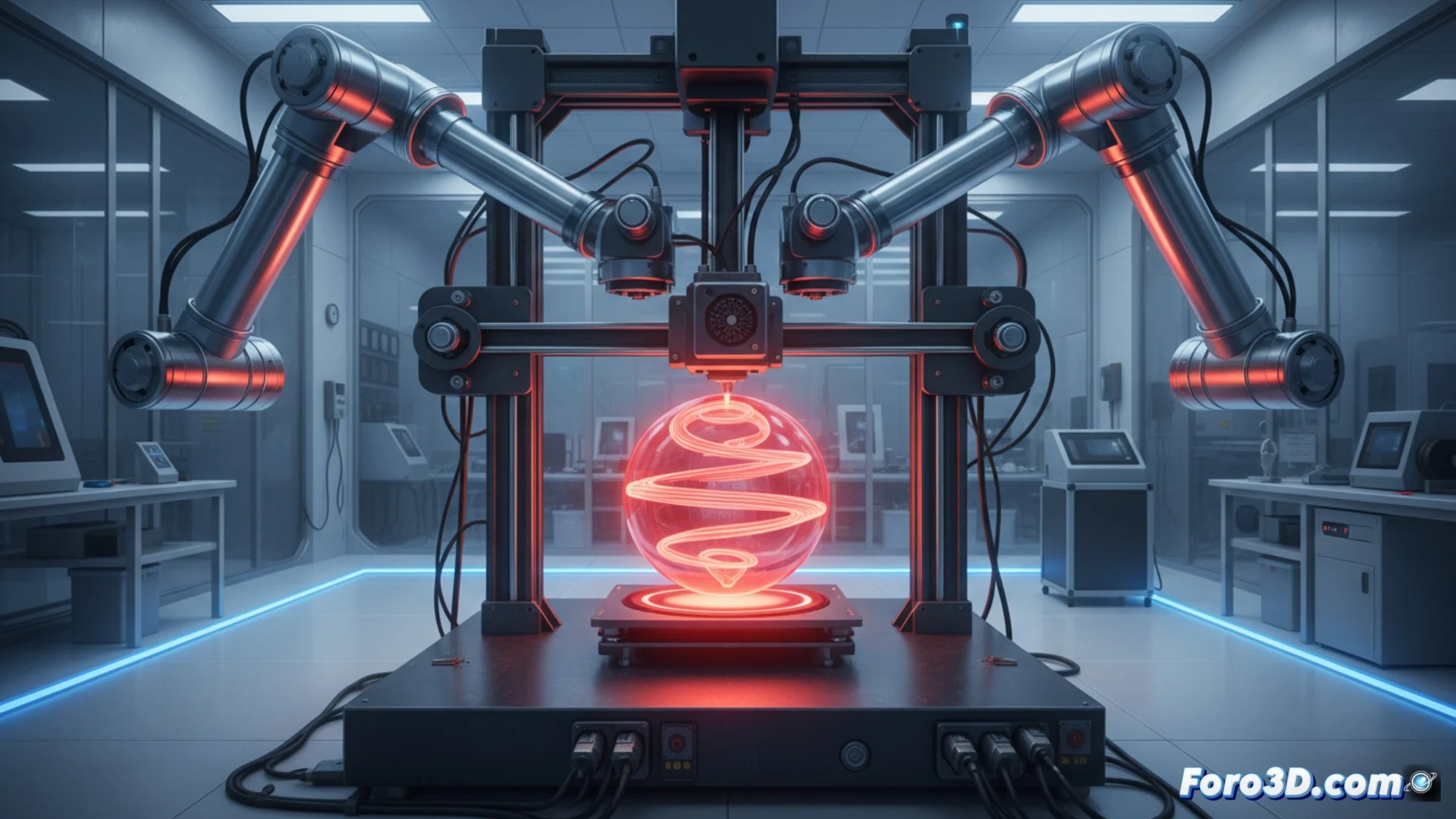

A South Korean company prints spherical containers without supports

The South Korean firm 3D Printing has unveiled an innovative procedure to produce spherical containers using additive manufacturing without relying on support structures. This breakthrough solves a persistent technical challenge in creating shapes with pronounced overhangs. The methodology enables the generation of hollow and sealed spheres in a single work cycle, optimizing the process and reducing filament consumption. 🚀

The key is precise nozzle control

The core of the process lies in precisely programming the extruder's path and managing variables such as speed and material flow rate. By depositing the molten thermoplastic at a defined angle and overlap, each newly applied layer is stably supported on the previous one, even in the most demanding curved areas. This eliminates the need to generate and then remove supports, a step that is often tedious and can damage the part's surface.

Main advantages of the technique:- Eliminates the step of generating and removing support structures, saving time and material.

- Improves the integrity and surface quality of the part as a continuous structure.

- Allows adaptation of the process to various thermoplastics used in FDM.

It seems gravity took a break in South Korea, where printers defy physical principles to build perfect spheres without scaffolding.

Potential uses in various industrial fields

This progress is important for sectors that need hermetic containers or parts with aerodynamic profiles, such as the aerospace, automotive, or consumer goods industries. Producing these components as a single piece without supports enhances their structural strength and aesthetic finish.

Sectors that can benefit:- Aerospace and automotive: For components requiring aerodynamic shapes and sealing.

- Consumer goods: For designing packaging or decorative elements with organic shapes.

- Specialized manufacturing: For prototypes or final parts that demand complex closed geometries.

A step forward in additive manufacturing

This method not only simplifies the printing process but also expands design possibilities in additive manufacturing. By intelligently controlling material deposition, new paths open up for creating objects that were previously unfeasible or very costly to produce. The technique demonstrates that, with an ingenious approach, fundamental technical limitations can be overcome. 🔧