A new technique combines 3D printing and laser to create scaffolds that regenerate bone

Regenerative medicine advances with an innovative method that fuses additive manufacturing and photonics. Researchers from Complutense University of Madrid and CSIC have devised a process to produce supports that serve as a base for bone tissue reconstruction. This approach promises to transform how complex bone defects are addressed. 🦴

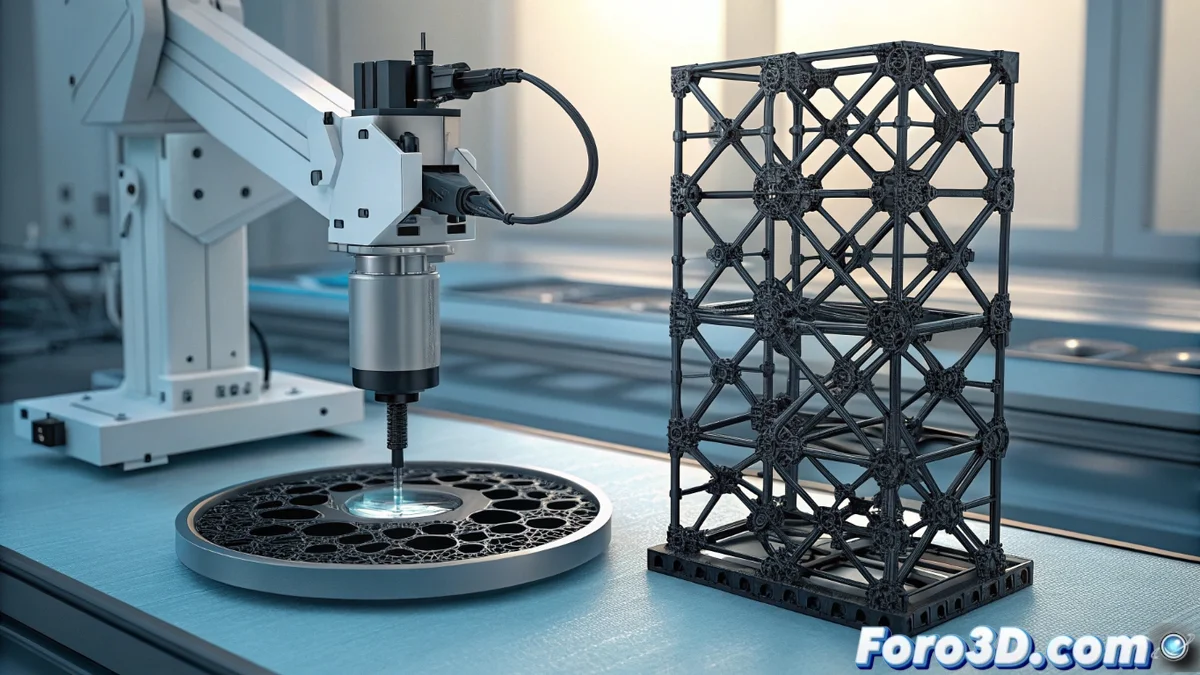

The synergy between printing and laser

The technique is based on two main stages. First, the base structure is 3D printed using a polycaprolactone filament, a polymer tolerated by the body. To enhance its properties, it is mixed with graphene nanoparticles. The differential step comes next: a CO2 laser modifies the material's surface. This treatment generates micro and nano-scale roughness precisely without resorting to chemical agents, which is key for interacting with cells.

Key advantages of the process:- Geometric customization: 3D printing allows adapting the scaffold's shape and porosity to the specific bone defect of each patient.

- Surface bioactivation: The laser creates textures that bone progenitor cells perceive, favoring their anchoring and beginning of differentiation.

- Enhanced material: The addition of graphene provides electrical conductivity and mechanically reinforces the polymer structure.

This advance opens a path to create custom implants that could be used in reconstructive surgery after trauma or tumor removal.

Promising results in the laboratory

Tests with cell cultures have yielded encouraging data. The scaffolds that received laser treatment demonstrated superior bioactivity. The cells not only adhered more effectively but also accelerated their natural mineralization process, that is, they began to deposit calcium phosphate (the main component of bone) more quickly.

Characteristics of the ideal scaffold:- Mimetic architecture: Its porous design mimics the natural bone structure, allowing vascularization and three-dimensional cell growth.

- Functionalized surface: The laser-controlled roughness acts as a physical signal that guides cell behavior.

- Biodegradable support: The base material is designed to degrade gradually as the new bone tissue takes its place.

The future of bone repair

This research places biomedical 3D printing at a new level, where not only the shape is manufactured, but also the biological function of the surface is programmed. The possibility of producing implants that perfectly adapt to the geometry of the lesion and that, in addition, activate and accelerate the natural bone regeneration marks a milestone. The path from the laboratory to the clinic is underway, showing that layer technology can build much more than prototypes. 🏥