A Danish institute and heatflow develop a 3D printed cooling system

An alliance between the Danish Technological Institute (DTI) and the company Heatflow is generating a breakthrough in how to cool servers. Their project is based on creating a liquid cooling system that uses additive manufacturing to produce key components, aiming to surpass the efficiency of conventional air conditioning methods. 🚀

Direct and customized cooling for critical components

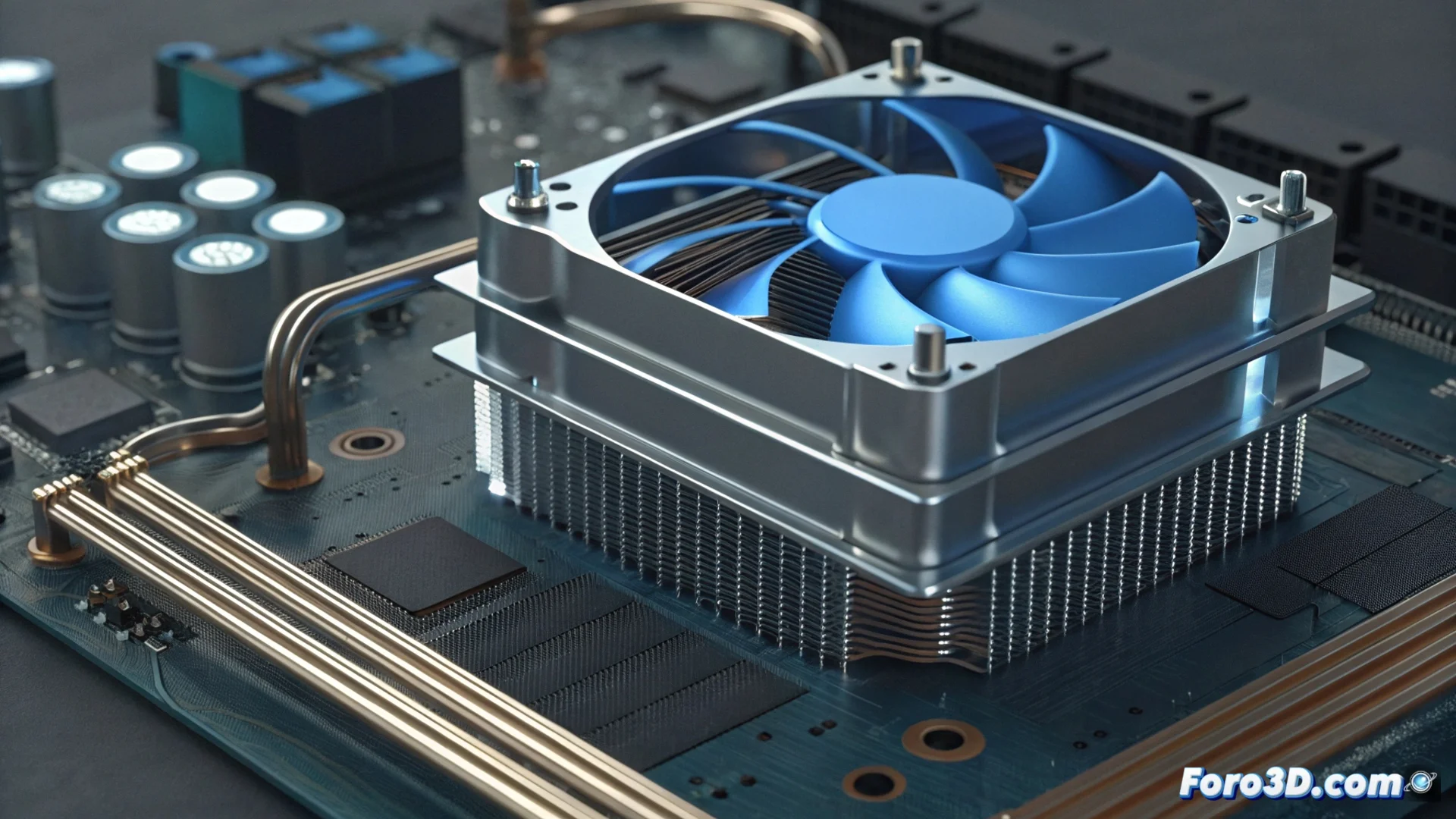

The technology is based on modules that connect directly to the parts that generate the most heat inside a server, such as processors (CPUs) and graphics processing units (GPUs). By manufacturing these heat exchangers in 3D, it is possible to adapt them to the exact shape of each chip, optimizing contact to transfer heat. A coolant liquid circulates through internal channels designed specifically to capture thermal energy more effectively. 💧

Key advantages of using 3D printing:- Allows creating complex internal geometries that are unfeasible with traditional production techniques.

- Reduces waste material by building only the necessary structure, making the process more sustainable.

- Facilitates customizing each piece for perfect thermal coupling with specific components.

The solution aims to reduce the overall energy consumption of the data center, as liquid cooling systems are usually more efficient than those that move large volumes of air.

Impact on efficiency and sustainability

Implementing this approach with additive manufacturing not only enables advanced designs but also contributes to a greater goal: making data centers consume less energy. By dissipating heat more directly and controllably, the load on the building's general air conditioning systems is reduced.

Benefits of the proposed system:- Greater efficiency in heat transfer compared to air cooling.

- Potential to save a significant amount of electrical energy.

- Servers can "sweat" their heat in a controlled manner, a metaphor that illustrates its optimized operation.

The future of server cooling

This joint development marks a path toward how to manage heat in digital infrastructure. By combining the customization enabled by 3D printing with the superior efficiency of liquid cooling, a new standard is established for dissipating thermal energy in high-density environments. The innovation demonstrates that additive manufacturing can solve critical engineering problems, taking energy efficiency to another level. 🔥