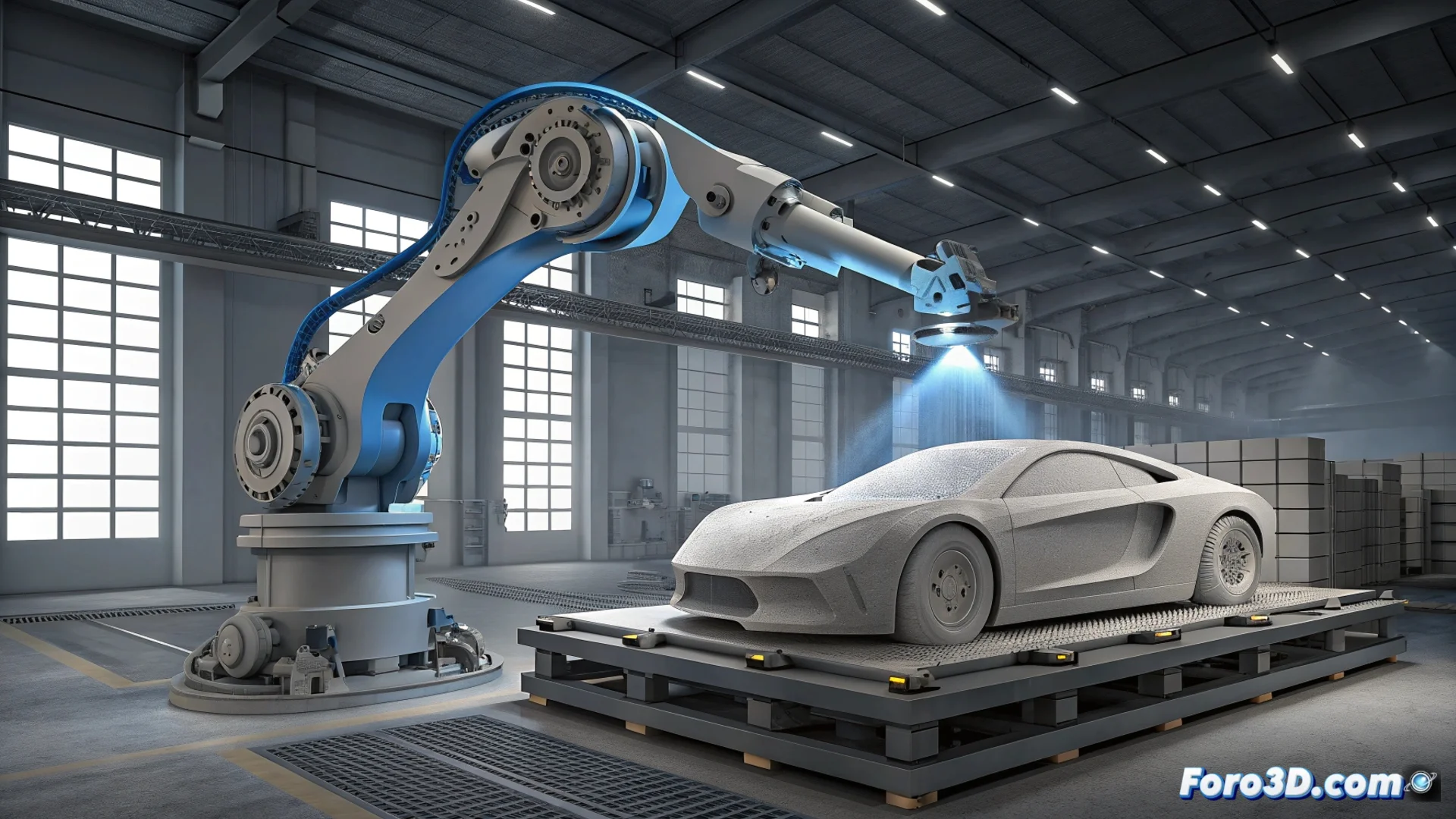

A Chinese factory produces body panels with 3D scanners

The automotive industry is evolving with the integration of digitization technologies. A factory in China has begun to implement a system that uses 3D scanners to manufacture body components, marking a change in how vehicles are developed. This process captures physical geometries and converts them into digital data that directs production machines, streamlining the entire cycle. 🚗

Fusion of digitization and direct manufacturing

The core of the system lies in combining 3D capture with computer-controlled machining. Technicians do not rely on complex blueprints, but instead scan a physical master model. A laser device collects a dense point cloud that defines every curve and surface. Specialized software processes this data to build an exact three-dimensional digital model, which subsequently guides robotic arms or CNC milling machines.

Key steps in the workflow:- Scanning the master: A clay model or existing part is digitized using a high-resolution 3D scanner.

- Generating the digital model: The software reconstructs the point cloud into a 3D mesh or production-ready NURBS surface.

- Programming the machine: The final 3D file is used to create G-code that controls subtractive manufacturing equipment.

This approach seeks the 'impact' of avoiding manufacturing errors, not that of the bumpers. It prioritizes absolute precision over manual methods prone to deviations.

Concrete advantages in automotive production

Adopting this technology generates tangible benefits in speed and accuracy. It drastically reduces the time needed to develop and test new designs, as it eliminates many intermediate stages of traditional molding. Companies can iterate designs more quickly and manufacture limited series or custom components efficiently.

Positive impacts on the production chain:- Accelerate prototyping: It goes from the physical model to the machined part in a continuous digital flow.

- Minimize human errors: Automating the copying process reduces deviations and ensures that every replica retains the original dimensions.

- Reduce costs: It decreases the need for rework, manual adjustments, and manufacturing multiple test molds.

The future of precise manufacturing

This case demonstrates how 3D digitization is transforming industrial manufacturing. It is not just about copying shapes, but about creating a perfect bridge between conceptual design and physical reality. The ability to capture and reproduce complex geometries with fidelity opens doors to more viable customization and faster development cycles in the automotive sector and beyond. 🔧