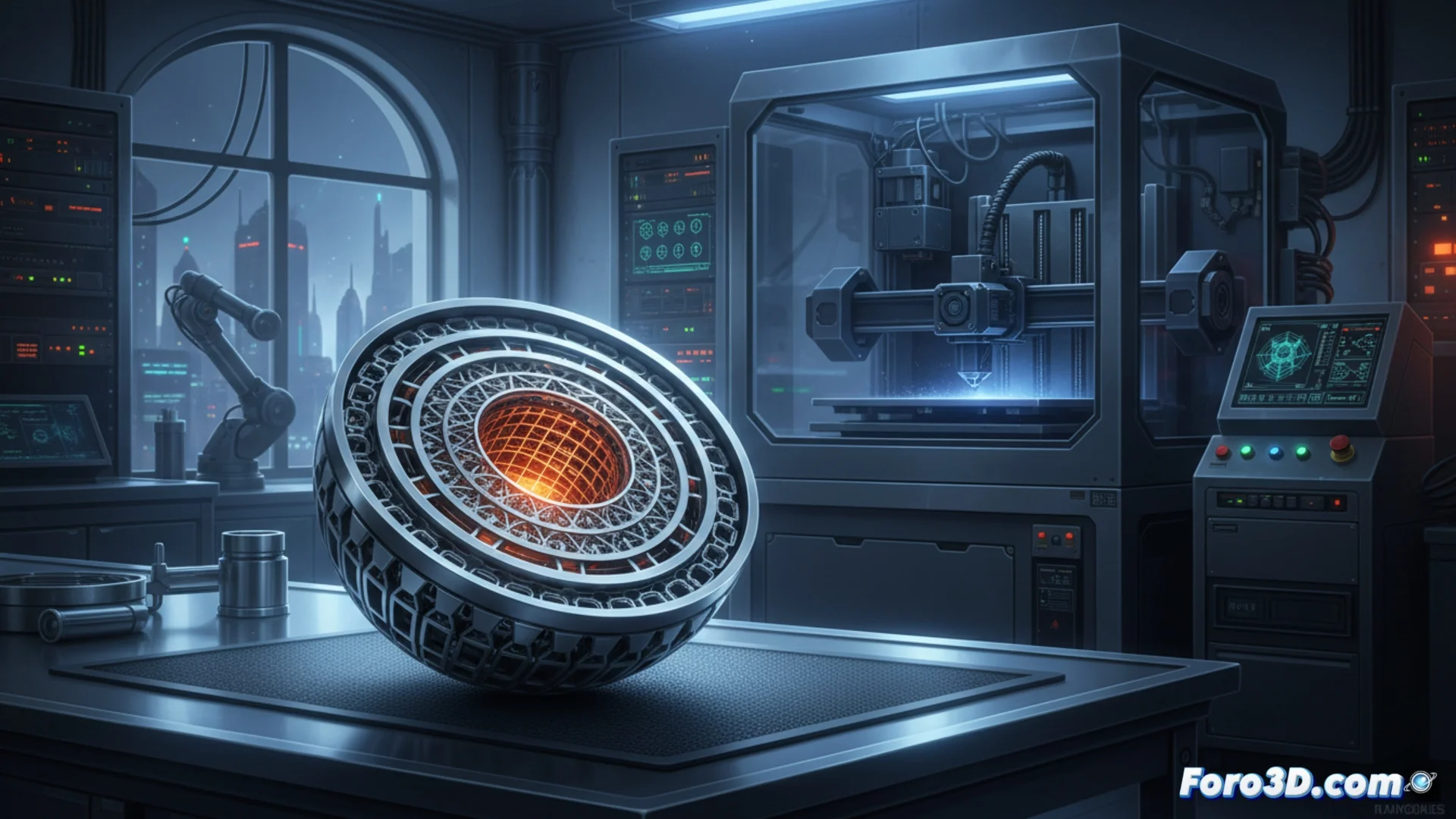

British consortium investigates manufacturing fusion parts with 3D printing

In the United Kingdom, an ambitious initiative called DIADEM has been launched. A team led by the University of Nottingham seeks to apply additive manufacturing to produce metallic parts destined for fusion energy reactors. This effort is backed by funding from the EPSRC's Adventurous Manufacturing program and brings together the United Kingdom Atomic Energy Authority with several companies in the sector. The goal is clear: overcome the barriers of traditional methods to create components that withstand extreme heat and pressure environments. 🔬

The core of DIADEM: designing interfaces between materials

DIADEM stands for Design of Interfaces for Additively Engineered Metamaterials. Its main work is not just depositing metal, but precisely designing the joints or boundaries where different materials meet within the same part. This is fundamental for building metamaterials with specific properties, such as superior heat tolerance and mechanical robustness. 3D printing allows layer-by-layer deposition control, enabling geometries and material blends that were previously unfeasible.

Key pillars of the project:- Focus on interfaces: Investigate how the junction zone between different alloys or materials behaves and can be optimized within an additively manufactured component.

- Create custom metamaterials: Use this capability to generate structures with properties not found in nature, specifically tailored for fusion challenges.

- Overcome geometric limits: Leverage the design freedom of additive manufacturing to achieve internal and external shapes that improve thermal and structural management.

Additive manufacturing allows depositing materials layer by layer with precision, opening the door to geometries and material combinations that were previously impossible to achieve.

A strategic collaboration to bring the technology to the real world

To ensure this research does not remain in the lab, DIADEM integrates top-tier industrial partners. The participation of Rolls‑Royce, the Manufacturing Technology Centre, and Aerosint ensures that the findings have immediate practical application. These organizations bring their deep expertise in advanced alloys, production processes, and 3D printing systems that can handle multiple materials simultaneously.

Benefits of the collaboration:- Accelerated knowledge transfer: The synergy between university, public research center, and industry shortens the path from concept to functional prototype.

- Focus on industrial applications: Technical challenges are defined and solved with their implementation in future commercial fusion power plants in mind.

- Early validation: Developed components can be tested and evaluated in environments and with criteria relevant to industry.

A crucial step to make fusion energy viable

The final challenge is monumental: manufacturing parts that do not fail under the brutal conditions of a fusion reactor, where conventional materials reach their limit. This project demonstrates that metal 3D printing goes far beyond rapid prototypes or decorative parts. It positions itself as a key enabling technology for one of the most promising and complex potential energy sources. DIADEM's work is not just about manufacturing, but about innovating in material design to contain a small star on Earth. ⚛️