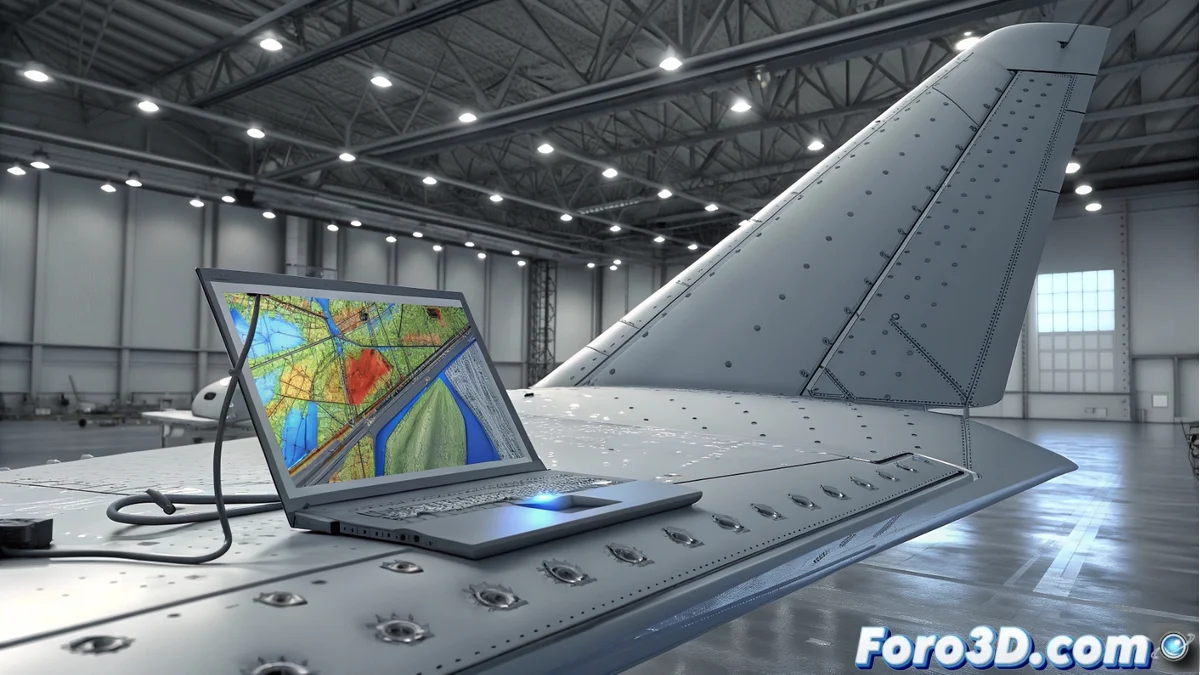

A 3D Scanner Maps Hail Damage on Critical Structures

When hail impacts delicate surfaces like an airplane wing or a solar panel, assessing the damage accurately is crucial for safety. Portable 3D scanning technology offers a solution, capturing the real geometry of each dent for in-depth analysis. 🛩️

Capturing Reality with Extreme Precision

A device like the HandySCAN from Creaform is used to record the complete topography of the affected area. This equipment generates a dense and precise point cloud, defining each imperfection at the micrometric level. This digital capture is the indispensable first step.

Key Advantages of 3D Scanning for Inspection:- Records the complete geometry without contact, preserving the surface.

- Achieves resolution that detects minimal variations in depth and volume.

- Produces an exact digital model that serves as an objective reference.

The worst consequence of a hailstorm is not the initial damage, but not knowing if the structure can safely perform its function.

From Data to Damage Understanding

The point cloud is taken to metrology software, such as GOM Inspect. Here it is processed to measure each individual impact: its depth, diameter, and the volume of displaced material. The software compares the scan with the original CAD model, creating color maps that clearly visualize deviations and severity.

Analysis Process in Metrology Software:- Import and align the point cloud with the theoretical model.

- Automatically measure quantitative parameters for each dent.

- Generate graphical reports with deviation maps for decision-making.

Simulating Behavior Under Stress

The precise geometric data is transferred to a finite element analysis (FEA) environment, such as Ansys. A virtual model of the structure is built and normal operational loads are applied, such as aerodynamic pressure or wind force. The simulation calculates how stresses are redistributed around the damages, identifying stress concentration points that could initiate a crack. This step is vital for determining whether to repair or replace. 🔧