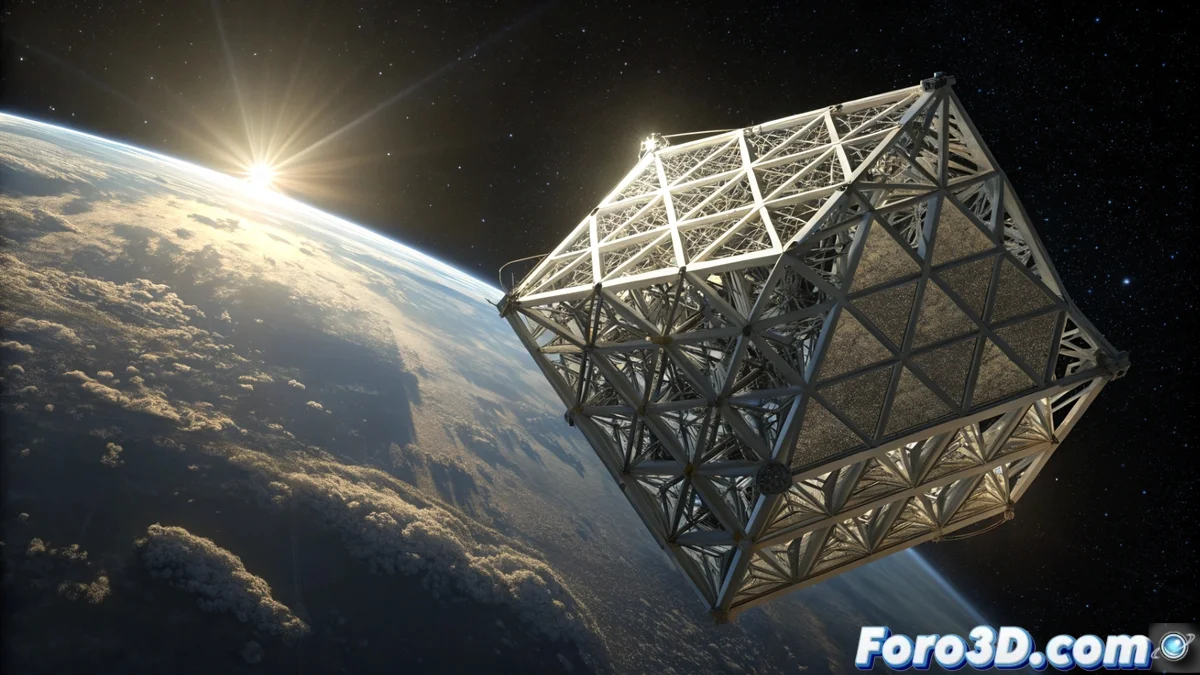

4D Printing Transforms Space Component Manufacturing

Aerospace engineering is advancing toward a model where structures are manufactured in a compact state and are capable of changing their shape on their own upon reaching space. This new paradigm is based on materials that respond to specific external stimuli, such as intense sunlight or vacuum, to adopt their final operational configuration. 🚀

How does the fourth dimension work in manufacturing?

The core technique is called 4D printing. It consists of producing three-dimensional objects using programmable smart composite materials. These materials have a "memory" that scientists define during the manufacturing process. Time acts as the fourth dimension, as it is the factor that controls when and how the structure's transformation occurs. The component only requires the correct environmental trigger to activate its predefined metamorphosis.

Key advantages of this approach:- Radically optimize space inside launch rockets, allowing large antennas to be packed into minimal volumes.

- Reduce the total mass of the payload by eliminating heavy and complex robotic deployment mechanisms.

- Decrease mission complexity and associated launch costs, as final assembly does not require human or external robotic intervention.

The old dream of sending flat-pack furniture that assembles itself finds its application hundreds of kilometers above, with a more ambitious purpose than assembling a bookshelf.

Solving Historical Logistical Challenges

One of the biggest obstacles in space missions has always been sending large-scale hardware using the limited space in rockets. 4D printing solves this problem by allowing structures to be launched in a small and lightweight container. Once in orbit, the component deploys autonomously, without requiring risky extravehicular activities to assemble it.

Autonomous transformation process:- Manufacture the component on Earth in a folded and compact configuration.

- Launch it into space inside a rocket, occupying a fraction of the volume it would need when operational.

- Expose it to the programmed environmental stimulus (sunlight, vacuum, heat) that activates the transformation.

- Observe how the material changes shape autonomously until it reaches its final and functional geometry.

The Future of Structures in Space

This technology marks a turning point for designing and building space infrastructures. By integrating the ability to transform directly into the materials, it opens the door to more ambitious, efficient, and economical missions. The concept goes beyond the simple antenna, imagining future habitats or solar panels that can self-assemble after launch, completely redefining how we explore and utilize the space environment. 🌌