4D Implants: When 3D Printing Gains the Dimension of Time

The frontier of medicine is being redefined with a new class of devices that transcend the static concept of the implant. 🧠 Manufactured using 3D printing, these elements incorporate a fundamental fourth dimension: time. Once placed in the body, they are programmed to transform their structure or degrade in a controlled manner, synchronizing with the patient's healing process. 🤯

Materials That Dialogue with the Body

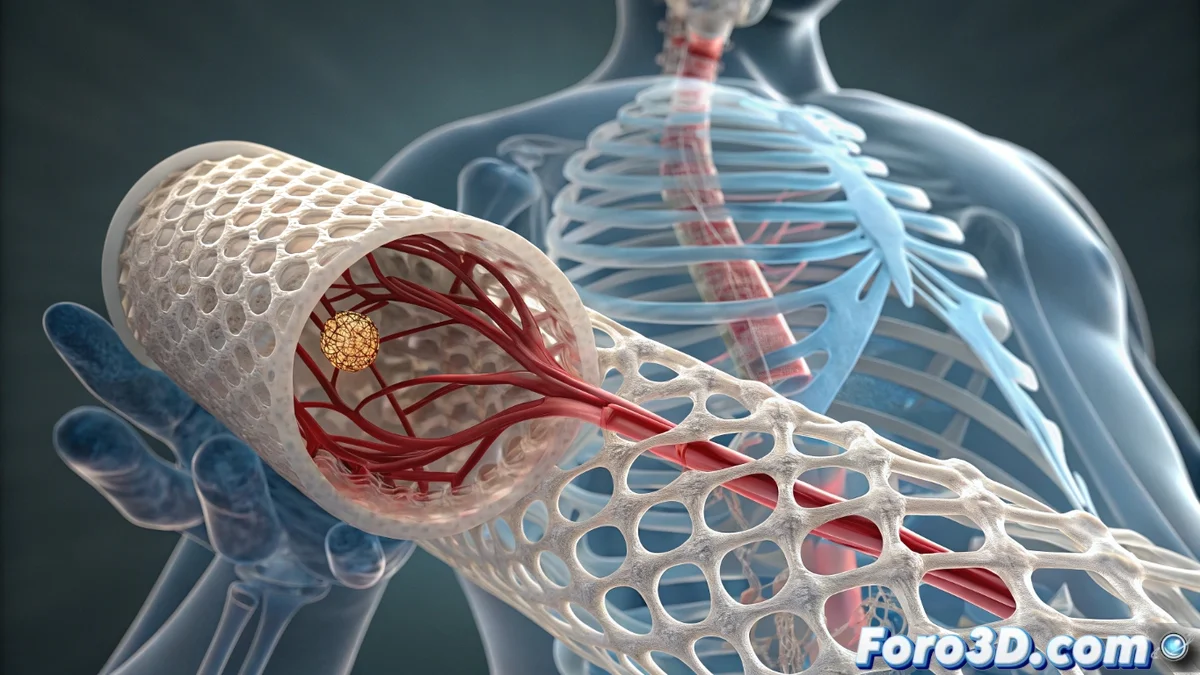

The core of this innovation consists of shape-memory polymers and other biomaterials designed to perceive and react. They are not inert; they respond to specific signals from the bodily environment, such as variations in temperature, acidity level (pH), or concentration of certain enzymes. This allows a device to perform its function autonomously and locally.

Examples of this dynamic interaction:- A vascular stent could expand progressively to adapt to the natural growth of a blood vessel in a child, avoiding repeated interventions.

- A bone support structure could degrade at a programmed rate, just as the natural bone regenerates and gains strength, eliminating the need for a second surgery to remove the implant.

- Drug releasers that activate their release only upon detecting the presence of a specific biochemical marker of a disease.

True intelligence is not in the device adapting, but in achieving that the body does not reject it for being too smart.

The Power of Personalized Additive Manufacturing

3D printing is the key enabling technology. It allows the production of intricate and completely personalized geometries that fit the unique anatomy of each individual. By combining this design capability with programmable materials, an initially static form comes to life and executes a sequence of actions within the organism.

Key advantages of this approach:- Less invasive treatments: Reduce surgical trauma and improve recovery.

- Improved efficacy: The device interacts directly with the patient's biology, actively assisting in healing.

- Personalized outcomes: The therapy adapts not only to morphology, but also to physiology and the temporal evolution of healing.

The Final Challenge: Intelligent Biocompatibility

While technical challenges in design and materials are being overcome, the main obstacle persists in the biological realm. The immune system is prepared to identify and attack what it perceives as foreign. Therefore, the greatest achievement will not only be to manufacture an implant that transforms, but to engineer one that the body integrates permanently and naturally, without triggering a rejection response against its own programmed "intelligence." The future of implants lies in this perfect harmony between materials engineering and human biology. 🔬