3D Systems Redefines Its Software Ecosystem: The Digital Unification of Additive Manufacturing

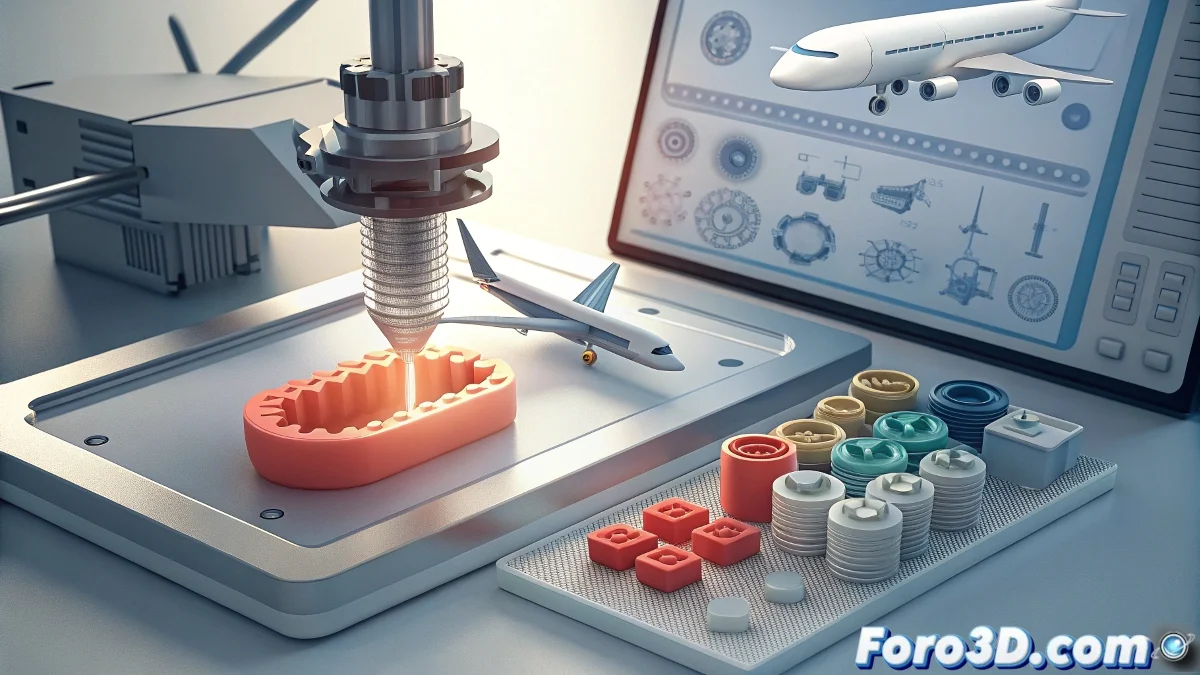

In a strategic move reflecting the growing importance of software in additive manufacturing, 3D Systems has announced a comprehensive update to its software platform strategy. The company, a pioneer in industrial 3D printing, is reorganizing its portfolio to create a more cohesive and integrated ecosystem spanning from design and file preparation to production management and post-process analysis. This restructuring is not just about new features, but a fundamental revision of how software can empower the entire digital manufacturing workflow. 🚀

Geomagic: Towards the Complete Design and Engineering Suite

The Geomagic platform emerges as the heart of the new ecosystem, with significant improvements in its mesh processing capabilities, reverse engineering tools, and tolerance analysis. The new version unifies previously separate products into a cohesive suite that allows seamless transitions between design, 3D scanning, and precision engineering. Improvements in the Control X module now enable faster deviation analysis and automated reporting, while the Sculpt tools have been optimized for organic and customized design. 🎨

Improvements in the Geomagic Suite:- Mesh processing up to 40% faster

- Enhanced alignment and registration tools

- Tolerance analysis with advanced visualization

- Native integration with metrology software

3D Sprint: The Evolution of Job Preparation

The file preparation platform 3D Sprint receives a major update that positions it as the operations center for additive manufacturing. New automatic nesting capabilities optimize part arrangement on the build platform, while predictive failure analysis has been significantly improved using machine learning. Most notable is the new integration with ERP and MES systems, enabling a continuous flow of information from quotation to production. The tool now also offers material recommendations based on specific applications. 📊

Software is no longer a companion to hardware - it is the brain of digital manufacturing

New Production Management Platform: Total Visibility

3D Systems introduces a new layer of management software that provides comprehensive visibility over the entire additive manufacturing operation. This system monitors printer status in real-time, manages job queues, optimizes equipment utilization, and generates analytics on operational efficiency. The platform enables tracking of individual parts throughout the entire process, from preparation to post-processing, creating a complete digital history for each manufactured component. This traceability is especially valuable for regulated industries like medical or aerospace. 👁️ Features of the new management platform:

- Real-time monitoring of multiple printers

- Intelligent queue and priority management

- Automatic productivity and efficiency reports

- Integration with existing enterprise systems

Open API and Partner Ecosystem

Recognizing that no single company can meet all market needs, 3D Systems is adopting a more open approach with a robust API that allows third-party developers and partners to integrate their specialized solutions. This strategy will facilitate the creation of custom connectors for specific CAD software, quality management systems, or advanced analysis tools. The company also announces a certification program to ensure the compatibility and performance of integrations developed by third parties. 🔌

Focus on Industry 4.0 and Digital Thread

The strategic update clearly positions 3D Systems to capitalize on the transition towards the smart, connected factory. The software ecosystem now fully supports the "digital thread" concept, maintaining continuous digital traceability from the initial design to the final part. This capability is crucial for applications where process documentation and validation are