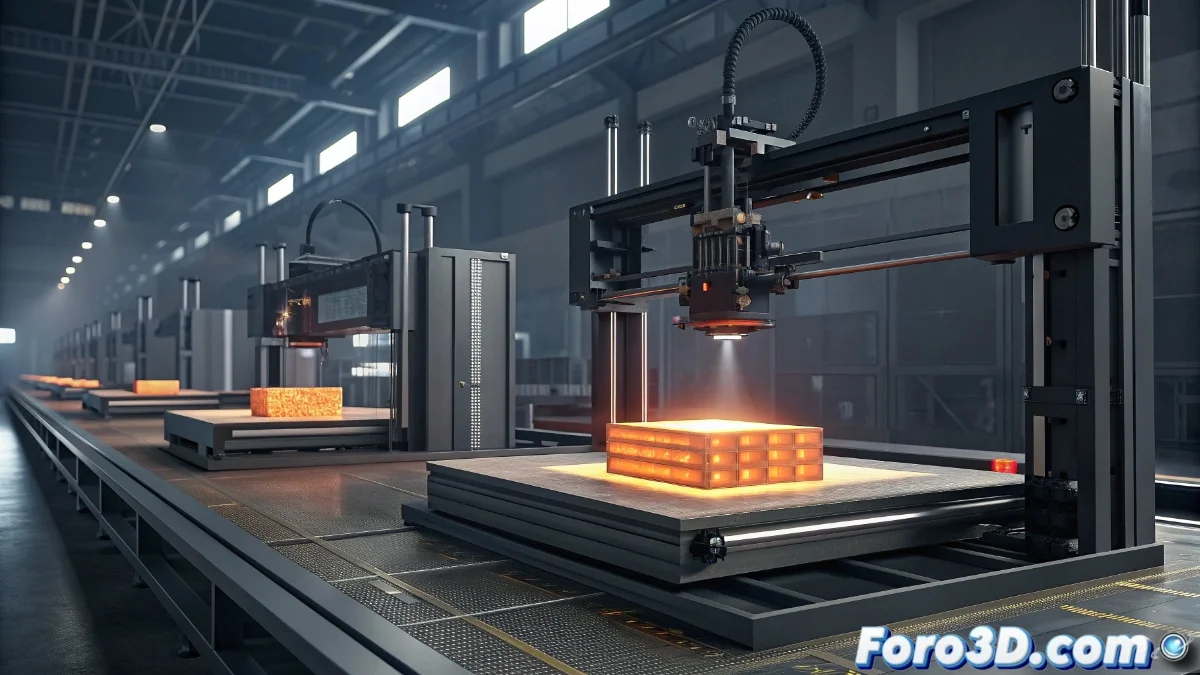

3D Systems Revolutionizes Stereolithography with the SLA 825 Dual System

The company 3D Systems has made a qualitative leap in the field of additive manufacturing with the launch of its innovative SLA 825 Dual system, specifically designed for industrial environments that demand maximum productivity and outstanding precision in component fabrication. This printer incorporates a dual-laser configuration that drastically increases production speed without sacrificing final quality, allowing users to manufacture intricate parts with greater efficiency and significant operational cost savings 🚀.

Technical Innovations of the Dual System

The SLA 825 Dual integrates significant advances in its architecture, highlighting a dual-laser mechanism that works synchronously to cover larger print areas with unprecedented speed. The machine features a build volume of 800 x 800 x 550 mm, establishing itself as one of the fastest large-format stereolithography solutions currently available. Furthermore, it includes an intelligent recoating system that optimizes resin usage and shortens the intervals between layers, guaranteeing dimensional accuracy of up to ±35 microns 💡.

Key Features:- Synchronized dual-laser mechanism for wide coverage and enhanced speed

- Build volume of 800 x 800 x 550 mm, ideal for large-sized parts

- Intelligent recoating system that reduces resin consumption and cycle times

With this speed, your quality control department will have to learn to work at the same pace as the machine, or perhaps they'll need their own dual version.

Practical Applications and Industrial Advantages

This technology is primarily aimed at industries such as automotive, aerospace, and medical devices, where functional prototypes and production components with consistent mechanical properties are in demand. Users will experience a substantial reduction in manufacturing lead times for medium and large series, as well as the ability to produce complex geometries that would be unfeasible or very costly using conventional methods. Compatibility with a wide range of advanced materials, including high-temperature resins and composites, further extends its applicability in demanding industrial environments 🔧.

Key Benefits for Users:- Significant reduction in manufacturing times for medium and large series

- Ability to manufacture complex geometries efficiently and economically

- Compatibility with advanced materials such as high-temperature resins and composites

Impact on the Additive Manufacturing Industry

The SLA 825 Dual not only raises the standards of speed and precision in stereolithography but also redefines productivity expectations in key industrial sectors. By integrating cutting-edge technologies like the dual laser and intelligent recoating, this solution allows companies to accelerate their development and production cycles while maintaining exceptional quality in every part. Its adaptability to diverse materials ensures it can tackle the most demanding challenges, positioning itself as an indispensable tool for the manufacturing of the future 🌟.