The Modern Alchemy of Glass with Laser

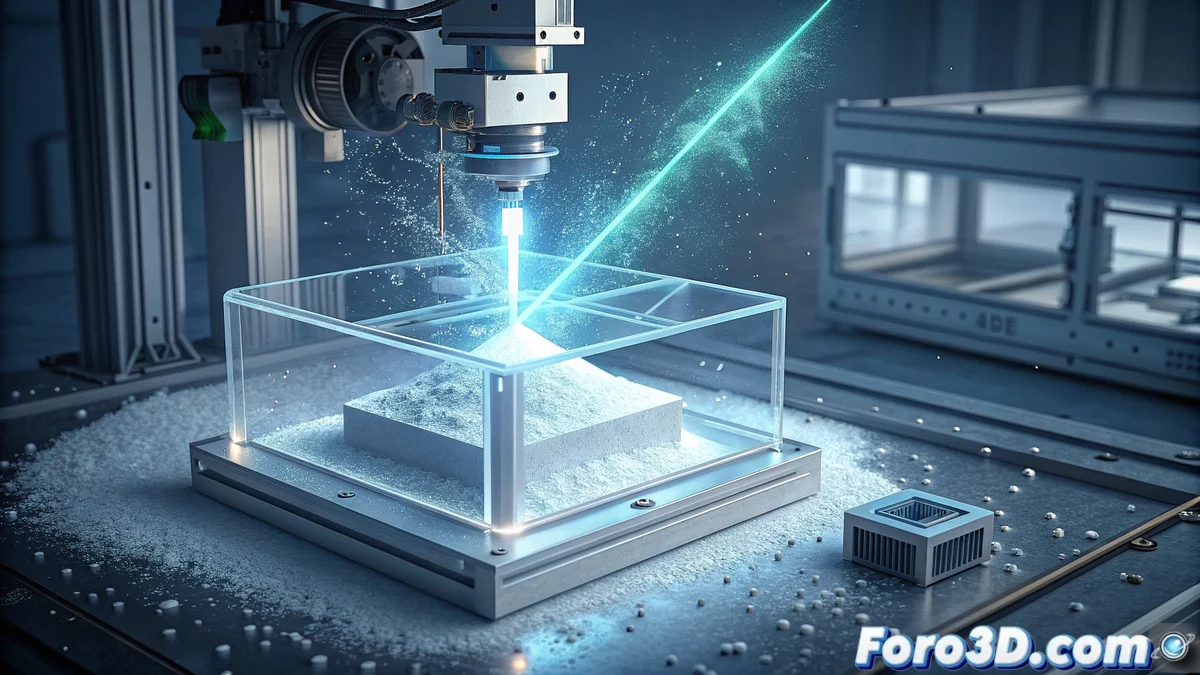

3D printing with silica powder and laser represents the most sophisticated and precise side of additive manufacturing with glass. This technique, which operates through selective laser sintering, transforms microscopic silica particles into solid objects through the controlled application of thermal energy. A process where micrometric precision meets the unique properties of the vitreous material.

The Choreographed Dance of the Laser over the Powder

The mechanism operates through a repetitive ritual of spreading ultra-thin layers of silica powder and selectively fusing them with a high-power laser. Each laser pass digitally draws the cross-section of the object, progressively building the complete piece from the base upwards. The unfused powder acts as a static support during the process, eliminating the need for additional support structures.

Stages of the Sintering Process

- Distribution of controlled-thickness silica powder layers

- Selective fusion using a high-power laser

- Progressive lowering of the build platform

- Removal and recycling of excess powder

Advantages of Laser Precision

This method significantly outperforms hot extrusion when it comes to fine details and surface finishes. The ability to create complex internal geometries, microscopic channels, and optically uniform surfaces makes it the preferred option for applications where every micron matters. The achieved transparency requires much less post-processing than other glass printing methods.

Applications Where This Technology Shines

- Optical components and custom lenses

- Microfluidic devices for laboratories

- Transparent and biocompatible medical implants

- Elements for the aerospace industry

A technology that demonstrates how the most traditional materials can achieve precision levels previously reserved exclusively for microelectronics.

For optical engineers and medical device developers, this technique means being able to prototype and produce components that would be impossible to manufacture using conventional methods. The ability to integrate multiple functionalities into a single monolithic glass piece represents a revolutionary advancement 🔬.

And all this while the excess silica powder patiently awaits its turn to be reused, demonstrating that in advanced 3D printing even waste has value... though you'll probably need a bank loan to acquire the printer that processes it 😅.