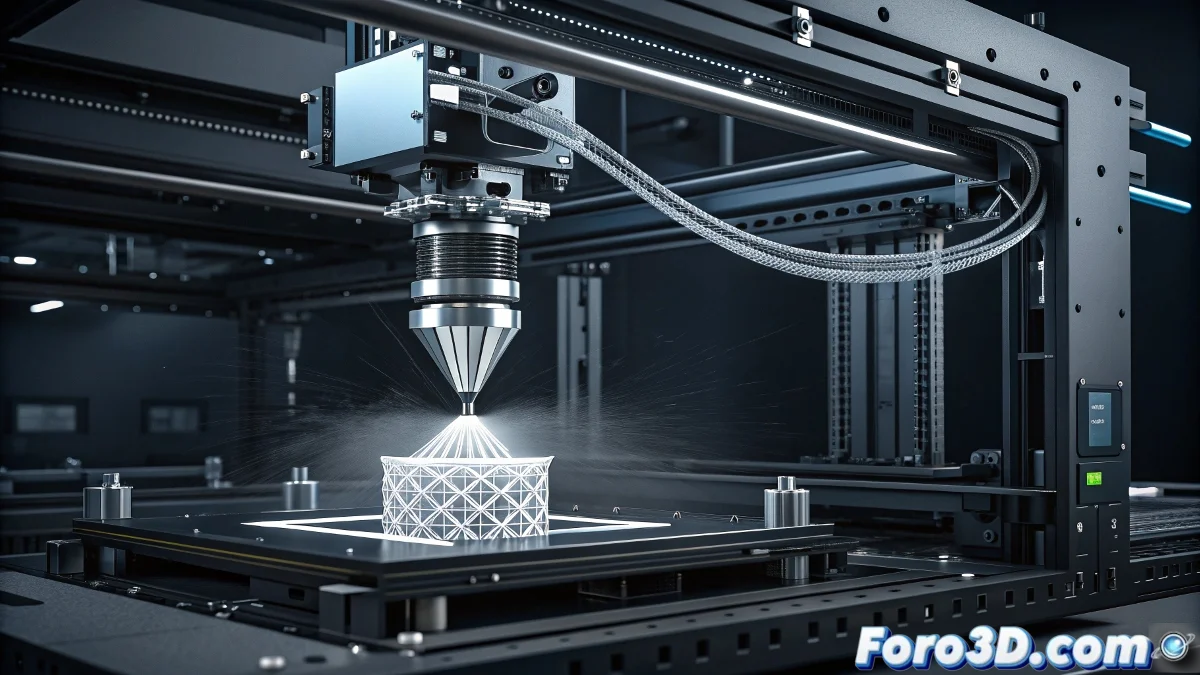

Multiplex Nozzle Technology

Additive manufacturing has just overcome one of its most significant limitations with the development of multiplex nozzles by American scientists. 🔧 This innovative system allows printing with two different materials simultaneously within the same layer, eliminating the need to stop the process to change extruders or make manual adjustments. The advanced print head can switch and combine polymers with distinct properties in real time, creating hybrid structures where rigidity and flexibility coexist in perfect harmony. This capability not only optimizes the mechanical performance of the resulting parts but also represents a dramatic reduction in production times by simplifying processes that previously required multiple stages and adjustments.

Impact on Industry

The implications of this technology extend to sectors where performance and efficiency demands are particularly critical. In industries such as aerospace and automotive, the ability to create ultra-lightweight parts that integrate different material properties into a single unitary structure marks a before and after in design paradigms. The medical field benefits equally, with the capacity to manufacture implants and devices that combine rigid zones with flexible areas that better mimic the behavior of biological tissues. This evolution toward integrated multifunctionality in unique manufacturing processes sets new standards for what can be achieved through additive manufacturing.

This opens the door to hybrid structures where a rigid polymer can be combined with a flexible one in a single piece

The Paradox of Slow Addition Resolved

This innovation represents the solution to a fundamental irony that has plagued 3D printing since its beginnings. Although conceptually called additive manufacturing, the true efficient addition of different materials was always hindered by the need for pauses and hardware changes. Multiplex nozzles finally resolve this paradox by allowing genuinely fast and simultaneous addition, transforming what was previously a sequential and fragmented process into a continuous and cohesive flow. This technical evolution brings additive manufacturing closer to its original promise of layer-by-layer construction without compromises in material versatility.

Mimicking Biology with Functional Materials

One of the most fascinating aspects of this technology is how, without directly intending to, it emulates strategies that nature has perfected over millions of years of evolution. Biological systems rarely employ uniform materials, but instead combine different substances in complex configurations that optimize specific properties. Bones, for example, mix flexible collagen with rigid minerals, while marine shells alternate hard and soft layers to achieve exceptional fracture resistance. Multiplex printing allows for the first time to replicate these natural strategies in manufactured environments, creating composite materials that work in perfect synergy like their biological counterparts.

Advanced Technical Applications

The capabilities of multiplex nozzles open up previously unattainable design possibilities with conventional 3D printing technologies. Each application leverages material versatility in a unique way.

- Gradient structures: Smooth transitions between different mechanical properties within a single piece

- Integrated supports: Soluble or flexible materials printed simultaneously as support structures

- Embedded circuits: Combination of conductive and insulating polymers for integrated electronics

- Variable textures: Surfaces with different friction coefficients in specific areas

Advantages over Traditional Methods

Multiplex printing not only accelerates processes but also introduces significant qualitative improvements in multiple dimensions of the final result.

- Elimination of weak interfaces between materials joined in separate processes

- Reduction of waste by minimizing material changes and purging processes

- Greater geometric freedom by not requiring access for multiple print heads

- Simplification of workflows by consolidating operations that previously required multiple stages

Future of Multifunctional Additive Manufacturing

This technology lays the foundation for even more ambitious evolutions on the horizon of digital manufacturing. Future directions point toward unprecedented material integration.

- Expansion to systems with more than two simultaneous materials for greater functional complexity

- Development of materials specifically designed to work together during the printing process

- Integration with artificial intelligence for automatic optimization of material distributions

- Applications in industrial-scale manufacturing with high-speed and high-volume systems

While nature perfected its composites over eons, 3D printing demonstrates that sometimes the best inspiration for technological innovation already exists in the natural world. 🐚 Because, let's be honest, what could be more elegant than a 3D-printed bone that knows how to behave like a real bone?