3D Printing Transforms Automotive Manufacturing with a Structural Component for the BMW i8 Roadster

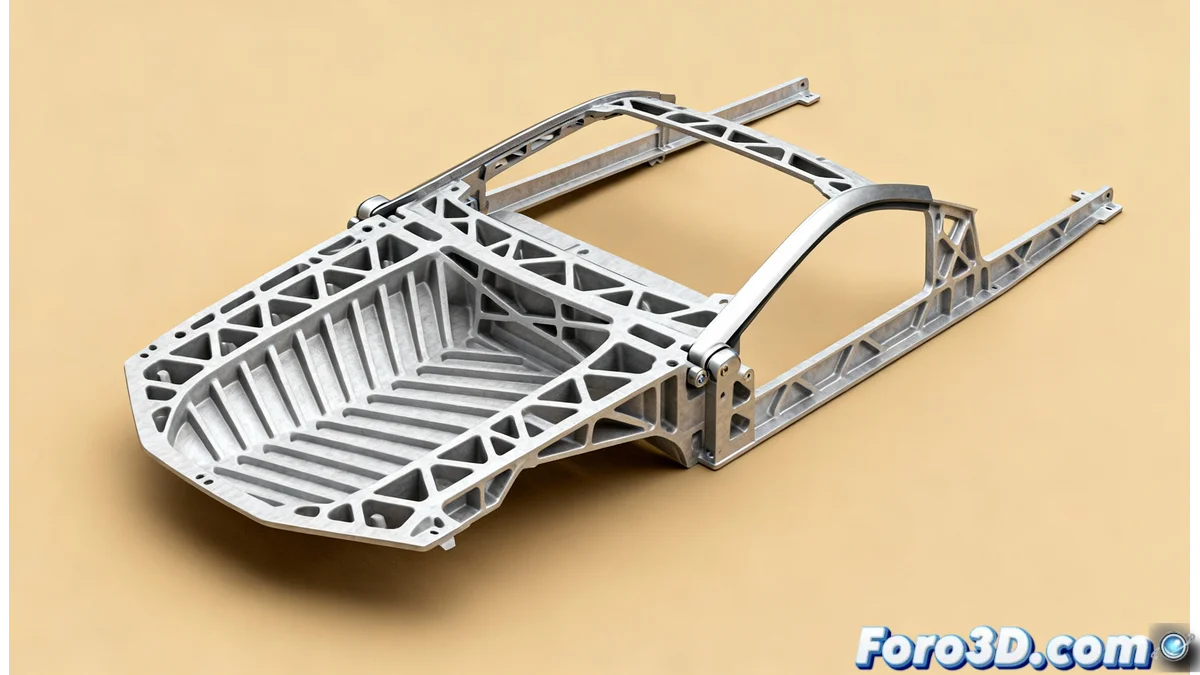

The automotive industry is experiencing a technological revolution with the implementation of a critical aluminum support manufactured using 3D printing for the BMW i8 Roadster. This structural element enables the operation of the convertible roof folding mechanism, demonstrating how additive manufacturing overcomes the barriers of conventional production processes 🚗.

Innovation in Structural Design

Engineers have leveraged the unique capabilities of 3D printing to develop an internal geometry with strategically distributed reinforcement structures. This approach eliminates unnecessary material while preserving the required structural rigidity, resulting in a component substantially lighter than traditional alternatives.

Advantages of the Optimized Design:- Significant weight reduction without compromising structural strength

- Complex internal geometries impossible to achieve with conventional casting

- Integration of multiple functions into a single unified piece

Additive manufacturing enables the materialization of engineers' most ambitious visions, transforming complex concepts into tangible realities that drive the future of automotive manufacturing.

Overcoming Traditional Limitations

Conventional manufacturing methods such as casting are technically and economically unviable for producing the complex internal channels and organic surfaces required by this folding roof mechanism. 3D printing of aluminum eliminates these geometric restrictions inherent to traditional molds.

Benefits of Additive Manufacturing:- Production of complex internal geometries with millimeter precision

- Reduction in the number of components through functional integration

- Excellent repeatability and considerably reduced production timelines

The Future of Automotive Manufacturing

The technological convergence between automotive engineering and 3D printing is redefining the boundaries of design and component manufacturing. This synergy enables the materialization of solutions that previously existed only in the conceptual realm, demonstrating that the path to automotive innovation inevitably passes through additive manufacturing 💡.