When 3D Printing Learns to Hold Its Breath

A group of scientists has discovered how to make large 3D printed parts stop looking like Gruyère cheese. The solution was as elegant as it was unexpected: putting a vacuum cleaner on them while they print. Yes, like when your grandma cleaned the sofa, but applied to advanced manufacturing.

"I never thought my Dyson vacuum would inspire a technological breakthrough" - said no scientist ever

The Problem of Invisible Holes

It turns out that large 3D printed parts had a dirty little secret: inside, they were more hollow than New Year's resolutions. These microscopic voids, technically called porosity, made the parts more fragile than a phone without a case. The new method reduces them by up to 75%, which in practical terms means:

- Parts that don't break when you look at them wrong

- Less material waste (and fewer engineer tears)

- The possibility of printing truly useful things, not just collectible figurines

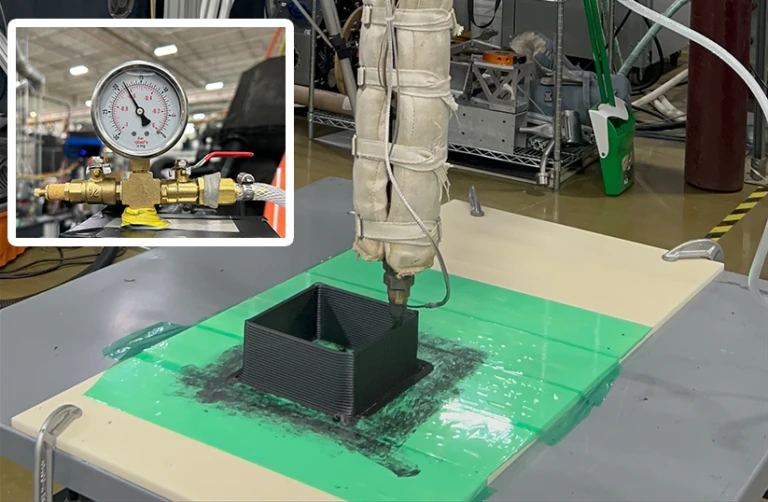

Vacuum Assistance: The New Industrial Must-Have

Vacuum-assisted extrusion works basically like those satisfying slime videos where they remove all the bubbles. The researchers added a suction system during printing that eliminates trapped gases, leaving the material more compact than a student's schedule during exam season.

The best part is that it works with any type of reinforcing fiber, proving that sometimes the most effective solutions are the simplest. Except when you try to fix the WiFi by restarting the router for the hundredth time.

Additive Manufacturing That Actually Adds Up

This breakthrough could revolutionize industries where strength is key:

- Aerospace: because at 10,000 meters, no one wants to hear "that was a print hole"

- Automotive: so cars last longer than just the warranty period

- Defense: because even tanks deserve to be printed with love (and vacuum)

The team is already working on continuous versions of the process, because in the industrial world, time is money, and slow 3D printers are like those friends who always arrive late: useful, but exasperating.

With these advances, we could soon see industrial 3D printed parts that can really keep up with production pace. The next step? Probably printing a vacuum cleaner that assembles itself while you print it. The irony would be delicious 🌀.